Media Questions? Media Content!

A couple weeks ago at Cultivate'22, I spent most of my time attending sessions and walking the floor in search of technical contacts and resources to share with you guys and gals. I also kept my ear to the ground, to pick up on any trends in terms of challenges you folks are facing when it comes to greenhouse production.

One of the common themes I noticed was related to growing media. There are new components on the market, new formulations, and custom and standard blends incorporating a wide range of ingredients, along with a seemingly endless range of questions to go along with them.

In our industry, when there are questions and confusion surrounding a topic, there’s usually research underway and resources being created to help you make sense of things. So it makes sense that in the past few years, we’ve run a lot of articles on growing media in GrowerTalks, and released a handful of in-depth Tech On Demand podcasts featuring media experts.

If media is on your mind looking ahead to 2023, here are some resources to check out:

Articles: THE LATEST ON GROWING MEDIA RESEARCH and SOILLESS SUBSTRATE SCIENCE FOR CURRENT & FUTURE GROWERS by a team of PhDs representing NC State, LSU and USDA-ARS

Article: PUTTING YOUR MEDIA TO THE TEST by the technical team at Premier-Tech Horticulture

Podcast: CONTROL YOUR INPUTS—REDUCE RISK THROUGH GROWING MIX SELECTION by experts from Berger

Podcast Series: Dynamics of Growing Media

Nick’s Tip of the Week: Poinsettia Best Practices

Each week, I’ll work with my buddy Nick Flax, a technical services expert at Ball, to share a concern that’s come up during one of his numerous calls with growers across North America. This week, he’s helping you start your poinsettias off on the right foot with a rundown of best practices.

PROBLEM: You’ve probably grown poinsettias for years and have a good handle on the ins and outs of this crop we all know and love. But with new team members coming on board, plus the inevitable curve balls that come at you every season, we should take some time to review best practices. Feel free to pass these tips on to your crew to make sure everyone’s on the same page and has an easy reference on some of the basics.

NICK’S TIP:This exercise is one that I go through with growers every year regarding best practices for growing poinsettias. Remember: There are many ways to grow poinsettias, not just one. Rather than playing the annual game of going from too wet/warm to too dry/cold, this year let’s all try to nail the optimum conditions from the get-go, and focus on what works best in your greenhouse and region:

Wet or Dry? Whether you prefer to keep your media constantly moist or you dry it down between irrigations, beautiful poinsettias can be grown using both moisture management strategies.

-

Wet: Monitor root health and apply fungicide more regularly to avoid Pythium issues. If you are irrigating with surface water, your risk of getting Pythium is significantly higher, so growing wet might not be the best choice in this case. Keeping crops wet also encourages excessive growth if you’re not careful. Use graphical tracking to hit your growth benchmarks and apply PGRs if needed to slow growth and hit your finished spec.

-

Dry: Fewer irrigations often mean less-frequent applications of fertilizer, especially if you are not doing constant-liquid-feed. Poinsettias are high-feeding crops, so ensure that your feed rate is appropriately adjusted to provide an adequate nutrient load for robust growth. However, feeding at a high rate runs the risk of spiking your substrate EC more easily. If you are growing your crops “high and dry,” regularly monitor your soil EC to avoid salt burn, which can open the door for root rot to strike.

Warm or Cold Finish? Cooler air temps yield a more toned finished plant, but plants grown under moderate temperatures, or “cold-finished” poinsettias, can be equally high-quality at finish.

-

Warm: If your air temperatures are too warm, bract coloring may be slowed, and color might not be as deep/rich at finish as desired. If you are a southern grower who can’t achieve cool temps, be sure to grow varieties that are well-suited to warmer climates. Keep in mind, warmer air temps will likely lead to unwanted growth later in production. Be sure to treat with PGRs earlier in production to curb excess growth without negatively impacting bract expansion and coloration. Also, flush excess feed out of the media toward the end of production to discourage additional soft growth, which will likely occur under warmer conditions if ample fertilizer is still available.

-

Cold: This strategy is much easier for northern growers, but how cold is too cold? Some great work was done at Purdue University that demonstrates the impact this strategy has on finished crop quality, height control, and less need for PGRs. However, keep in mind that cold-growing will reduce water uptake and adjustments to your irrigation frequency and timing are critical to avoid disease issues. Overwatering under cool conditions will lead to Pythium late in production when it hurts most … when they’re almost done! Additionally, if irrigations aren’t timed correctly, excess humidity can build up, cause condensation to rain onto bracts, and cause Botrytis to render them unsalable. Water early in the day, increase air flow and push humid air out of the greenhouse before dusk, and apply foliar fungicides to reduce risk of late-season crop losses.

Outdoor Finishing of Fall Pansies & Violas

To make sure your plants finish uniformly and on time, follow these key steps to ensure strong take-off and growth this fall.

Feeding

-

Feed plugs before planting with 150+ ppm from 20-10-20 or other pansy fertilizer. At 200 ppm, the optimum micronutrients, nitrogen and phosphorus will be around the roots, ensuring the plants will take off and grow rapidly.

-

Planting and then feeding doesn’t result in uniform fertilization to all the roots, due to the “umbrella effect” that occurs when you water right after planting. Make sure that the fertilizer is in the plug not around the plug.

Applying Boron

Irrigation water should have at least 0.5 ppm boron with every watering to make sure that boron is not limiting. Be sure to check your irrigation water for the amount of B, as levels higher than 1.5 ppm can be toxic. Applying extra boron during periods of high relative humidity and warm nights {>70F} will make sure that boron is not limiting. When boron is limiting, tip abortion can occur.

Outdoor Growing-on Fertilizer

-

During periods of high relative humidity and warm nights, apply calcium (Ca) and boron (B) fertilizers since Ca and B are not absorbed during hot, humid conditions. The six-packs pictured above show inadequate Ca and B in the first weeks after transplant.

-

Use fertilizers with high Ca levels and low ammonia levels (such as 15-0-15 or 14-0-14) after the initial feed if the water quality allows. Most fertilizers do not have sufficient B. The recommended rate in the fertilizer solution is 0.5 ppm. Supplementing with B from Solubor or Borax is needed to prevent distorted growth.

-

If B deficiency symptoms appear, apply a one-time application of 4-6 ppm B to prevent further distorted growth. Multiple applications at high rates can cause herbicide-like symptoms.

Fungicide Treatments

-

Rapid plant collapse, lower leaf yellowing and black roots are all symptoms of potential Thielaviopsis infections.

-

A thiophanate-methyl fungicide, such as Cleary’s 3336 (1 lb/100 gallons), applied every 7-14 days during rainy periods will reduce the chance of Thielaviopsis outbreaks.

-

Your plugs should have been treated within 14 days of shipping, so a follow-up application is needed within one week of receipt to protect plants from infection.

Quick Tech Tip: Ca Deficiency in Cabbage & Kale

Young leaf distortion and tip atrophy (tip stops developing) are signs of calcium (Ca) deficiency in flowering cabbage and kale.

These plants have a very high requirement for Ca if you want normal leaf development. The plants will start by having translucent, water-soaked areas on the margin of the leaves. After a short period, the margins will burn, and the leaves will be distorted and fail to size up. The younger leaves will stop any normal development and will become stunted.

One of the diagnostic descriptions of Ca deficiency is “little-leaf syndrome” due to the requirement for Ca to promote normal leaf expansion. With severe Ca deficiency the tips become atrophic and growth stops. This problem is more severe when the nighttime temperatures and relative humidity (RH) are high. Once the temperatures or RH decline, the plant resumes normal growth.

Cultivate 2022: Compatibility of Modern Insecticides with BCAs

Last week, I shared recaps of a couple educational sessions I attended at Cultivate’22, and I heard from some of you that it was good to read notes on sessions you didn’t have a chance to attend. Well, I’m a notetaker, and I sat in on a number of presentations, so I’ll keep going this week.

One of my favorite talks of the show was a forward-looking discussion of “modern” greenhouse chemicals and how they are being developed and deployed in conjunction with biological control agents (BCAs).

The presenter was Carlos Bogran, a technical manager with OHP, Inc. Carlos covered the latest research-based knowledge on the mode of activity and compatibility of common insecticides, and offered suggestions and tips on how to use them effectively before, during and after releases of beneficial BCAs like predators and parasites. Chemical controls are still the #1 way to manage greenhouse pests, but biological control has evolved to a standard. To me, it seems like the future will combine widespread use of biologicals along with selective compatible pesticides. And it also seems that today, the word “chemicals” includes cutting-edge biopesticides. Perhaps the lines are blurring, but I believe the reality is that horticulture is evolving.

Here are some of the notes I took during this super-informative session:

-

Modern insecticides include botanicals and microbiologicals, as well as novel insect growth disruptors and Diamide insecticides.

-

BCAs include predators, parasitoids and antagonists or entomopathogens.

-

There are three types of biocontrols: classical/importation; conservation, which enables natural enemies; and augmentation, the most common, which shifts the balance to make the biocontrols greater than the pests.

-

In augmentation, we’re less concerned with reproduction of the biocontrol agent and the effect of pesticides on its long-term health.

-

Many predatory mites are often not impacted by traditional pesticides because they are not insects.

-

Parasites spend a lot of time cleaning themselves. Some have a unique cleaning habit to remove bacteria and fungus spores that can be used to control pests.

-

Many pesticides that are classified as “soft on beneficials” are harmful to them because risk depends on toxicity and exposure. Concentration and application frequency are critical factors to consider, not just toxicity.

-

Diamides are one of the newest pesticide classes and include selective neurotoxic compounds—sort of synthetic biological insecticides.

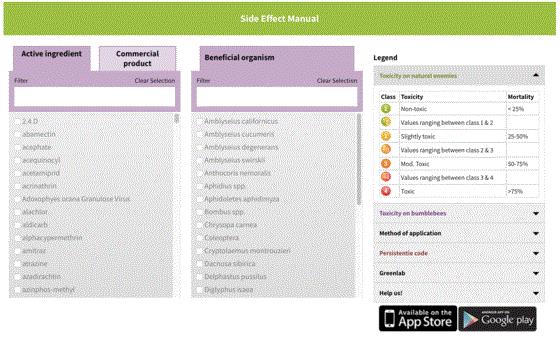

Check out this SIDE EFFECTS MANUAL from Biobest. Carlos refenced it a couple times and used the 1-4 scale of toxicity in his presentation. It looks like a comprehensive tool for determining the safety of many active ingredients to a range of biocontrol agents. It’s available at the link above and also as an app.

Finish Line ...

I actually wrapped up this newsletter early this week (I'm writing this on Tuesday) because tomorrow morning I’m off to West Chicago, Illinois, for the annual BALL SEED CUSTOMER DAYS, Thursday and Friday on the grounds of our world headquarters. It’s a beautiful time of year to visit “the mothership” because acres of gardens on the property are in full bloom, primed for this week’s activities. I hope to see some of you in The Gardens at Ball!

If you’re there, find me and let’s chat about any technical or cultural concerns you have from the past spring or summer. I’d like to learn more about ways we can share information to help you out.

If you can’t catch me beforehand, you’ll see me taking the mic and moderating a panel Friday in the main tent titled Production & Planning: How to be Successful in 2023, featuring Ball Seed National Sales Manager Jim Kennedy, as well as two growers who’ll all have thoughts on how to approach the coming year. Afterwards, I’ll be hanging out around the tent and more than happy to meet with you.

Before I close this newsletter, I want to issue a correction from last week’s edition. I incorrectly identified the geography of the presenter of the temperature management session from Cultivate. I wrote that Dr. John Erwin is at the University of Minnesota. I was quickly corrected by my good pal Dr. Marvin Miller that John spent many years at Minnesota but is now happily lending his services to the University of Maryland. My sincere apologies ... and a shout out to Marvin for reading carefully—love ya’ Marvin!

Please feel free to send your comments, constructive criticism and topic ideas to me at bcalkins@ballhort.com.

Bill Calkins

Editor - Tech On Demand

This email was received by you and 25,915 other fine subscribers!

If you're interested in advertising in Tech On Demand, contact Kim Brown ASAP and she'll hook you up.