Todd’s Top Transplant Tips

For some of you, crops are growing quickly and you’re anticipating spring shipping. For others, transplanting continues, and greenhouses are filling up.

If you’re still knee-deep in transplanting, I want to share a video we made to help your team through the process. Although this might be a refresher, it’s always good to share resources like this with your entire team, especially newer members.

Dr. Todd Cavins is one of our Tech On Demand experts, and thanks to his background as a professor, coupled with more than a decade of experience working directly with greenhouse operations of all shapes and sizes, his style is relatable, concise and no-nonsense.

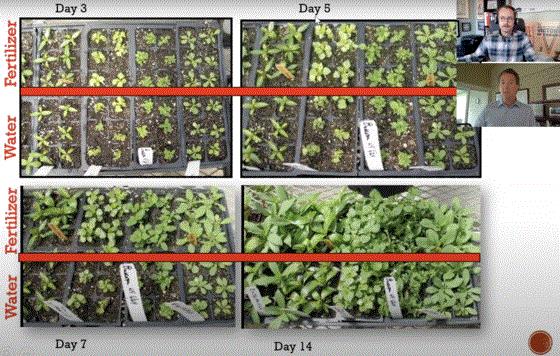

In TODD’S TOP 5 TRANSPLANT TIPS, he shares what you need to know to successfully transplant crops, complete with photos, tips and a time-tested feeding method. Here’s what he covers:

-

Get started immediately—Don't delay!

-

Applying fungicides in the plug or liner tray

-

Plug and liner moisture at transplant

-

Feeding your transplants

-

Cycling your irrigation

Nick’s Tip of the Week: Unrooted Cutting Challenges (Pt. 2)

Each week, I’ll work with my buddy Nick Flax, a technical services expert at Ball, to share a concern that’s come up during one of his numerous calls with growers across North America. This week, he’s on to the second part in his miniseries on the URC challenges he’s helping growers overcome this time of year.

If you didn’t catch last week’s tip, in which we covered moisture management for unrooted cuttings (URCs), be sure to check it out.

As a follow-up to last week, a grower reached out with questions on moisture management for callused cuttings. If you’re not familiar with this product form, think of it as a cutting that is one-third of the way rooted (a callus is already formed at the base) when you receive it. Many suppliers offer callused cuttings for different annual bedding plants, but here’s a nice example of Ball FloraPlant’s Genesis program for more details.

Moisture requirements for callused cuttings are significantly lower than most raw URCs. Moderate misting is often only needed for the first few days (at most); the goal should be to turn off the mist completely as soon as possible.

After the first few days after sticking, only apply mist if cuttings begin to wilt slightly. Also, be sure that the growing media does not get above a moisture level of about 4 on the 1 to 5 scale (1 = air dry, 5 = saturated). Overly wet media will cause the callus to continue growing and delay formation of roots, so it’s critical to run drier than you would raw URCs.

Now on to the second part of URC challenges: focusing on temperature management:

PROBLEM: Fundamentally, temperature controls the rate of plant development on a macro scale (i.e. leaf unfolding rate) and all the cell-level biochemical reactions that drive it. Each genus or species has an optimal temperature range where all the plant’s biochemical machinery runs quickest and most efficiently. Because URCs are incomplete plants that lack roots and, subsequently, cannot grow normally under average greenhouse conditions, the goal is to encourage roots to develop as quickly as possible.

NICK’S TIP: Precisely managing temperature in propagation is critical to get cuttings rooted as quickly as possible. Much like moisture management, temperature should be monitored and managed before, during and after sticking. This week, let’s consider temperature management before and at stick.

Prior to sticking. While it’s impossible to control what occurs to cuttings before they arrive at your facility, knowing what is happening to them in the supply chain can help you prepare for action when they arrive. Keep an eye on any tracking information that you receive from your URC supplier, monitor for any delays, and make necessary preparations if your cuttings get held up somewhere. Ideally, they will arrive at an optimal temperature (somewhere around 40 to 45F), but depending on the time of year and your location, cuttings can get hot or cold in the box. However, if either of these occur, this doesn’t mean all hope is lost for them.

When cuttings are exposed to freezing or near-freezing temps in transit, thoroughly inspect them upon arrival.

-

If they are soft and mushy, they should not be stuck. Cold-sensitive crops like sweet potato vine is a great example of a species that does not tolerate chilling or freezing temps during shipping.

-

If cuttings are still firm and only have minor chilling symptoms, quickly place them in a cooler at around 39F (4C). Allow cuttings to acclimate for about 24 hours and reevaluate. Cold-sensitive species should be acclimated at their lowest safe temperature (generally around 50 to 55F/10 to 13C).

-

If cuttings look okay after acclimating, increase to normal cooler temperatures (40 to 45F) and stick them ASAP.

When cuttings potentially get “hot in the box” during shipping, check cutting temperature upon arrival with an infrared thermometer.

-

Measure the URC stem temperature and not the internal box temp or the temp of the plastic bag in which cuttings are packaged. Stem temperature will give you the most-actionable information, as this is a direct measure of what the URC is experiencing, rather than the packaging around it.

-

For most crops, heat-related stress will likely be minimal if stem temperature is in the 55 to 60F (13 to 15.5C) range. Check for cutting breakdown, but oftentimes these can be stuck right away. However, give stick priority to these over URCs at proper temps or other greenhouse operations. Do not let them sit around!

-

If stem temperatures are much above 60F (13C), place them in a humidified cooler for 24 hours and check again. If cuttings are fully recovered, stick as usual.

Anytime cuttings experience adverse conditions in transit, be sure to apply a fungicide ASAP after they are stuck and fully hydrated. Stress incurred from being too hot or cold will predispose them to disease out in your propagation area, so reduce the risk with timely, preventative treatment.

At stick. The answer to the question, “What is too cold or hot for a given species in transit?” can be a bit murky, but the ideal URC temperature at stick is very straightforward. Until cuttings are ready to be stuck, maintain them at their lowest safe temperature in a humidified cooler. Failure to do so can result in poor cutting performance, even if they were in ideal conditions throughout the postharvest and shipping process.

-

Warm temperatures will encourage water loss and cause cuttings to start burning through their energy reserves (carbohydrates stored in the stems).

-

While not always practical, keep the minimum number of URC bags out and open on the sticking line as possible at any given time.

-

If you want to reduce the number of trips back and forth between the cooler, place insulated coolers along the sticking line as staging areas for the next batch to prevent excessive warming prior to stick.

PGRs Demystified

I’ve seen a handful of plant growth regulator (PGR) questions popping up in the Tech On Demand activity reports, as well as in our Greenhouse Tech Team Facebook Group. It’s probably a good time to direct you to some resources that can help you with PGR selection and use.

One easy-to-digest document I found is from Purdue University Extension, in partnership with a group of researchers from leading universities. It’s one you can print out and post for your production managers to reference when needed.

The Purdue reference explains that many PGRs successfully reduce internode elongation, decreasing plant height to control the crop growth. Some of the active ingredients in this category are ancymidol, flurprimidol, chlormequat chloride, paclobutrazol, daminozide and uniconazole. Other PGRs include plant hormones or gibberellins, which impact cell elongation and division, as well as flowering. All of these and more are covered in this POCKET REFERENCE on PGRs for greenhouse production.

Grow Pro Webinar March 22: Calculating LED Cost

Even if you’re not currently using or trialing LED lighting, you’ve probably been wondering if it’s right for your operation. How will your crops react? How steep is the learning curve? These are common questions, but exploring LEDs often starts with “how much is this going to cost, and is it worth it?”

This question is the topic for an American Floral Endowment webinar next week, presented by one of our industry’s leading lighting researchers, Marc van Iersel from University of Georgia. Here’s what you can expect from CALCULATING THE COST OF LED LIGHTING:

This webinar will showcase free tools that can be used to estimate both capital and operating expenses associated with supplemental lighting in greenhouses.

Supplemental lighting is often necessary for year-round production of greenhouse crops. However, the expenses associated with lighting can be high. That includes both the capital expenses associated with buying or leasing lights, as well as the electricity costs associated with running the lights. Capital expenses are easy to determine based on quotes from suppliers. However, operating expenses are much harder to estimate, since electricity use depends on the lighting needs of the crop, greenhouse configuration and local weather conditions.

Learn more and sign up HERE.

TECH TIP: Verbena Deficiencies

In the past week, the Tech On Demand has been in detective mode helping you and your peers solve greenhouse mysteries, usually from photos, texts and emails.

Here’s a photo we got from a grower who wondered why he was seeing lower leaf chlorosis on a verbena crop. Our team worked with the grower, asking the necessary questions and running through many variables to come up with this diagnosis:

Magnesium deficiency is commonly reported as lower-leaf, interveinal chlorosis. It can happen when too much calcium nitrate is applied in an attempt to keep plugs toned. I think this is the most probable explanation. I would suggest an application of Epsom’s salts (MgSO4) at 1 lb. per 100 gal. of water and see if that doesn’t help correct.

In addition, old PGR phytotoxicity may also be plausible. It appears the new leaf expansion is good, so if this is the cause, there’s no need to be concerned. A distant possibility is potassium deficiency. This can happen when plants don’t have enough fertilizer and are grown cool.

QUICK TIP: Cold Damage

Here’s another photo we received in the past week. The weather lately has been unpredictable (to say the least) and some of your cuttings shipments may be arriving with cold damage. This was the case here:

The necrotic spots seen in the photo, as well as cutting breakdown, are most likely due to cold damage in shipment. Your best bet is to treat with a preventative fungicide for Botrytis in an effort to reduce disease pressure on the damaged foliage as the plant grows out after the cold snap.

Finish Line …

In a couple weeks, your friendly neighborhood Bobbleheads will head West for California Spring Trials to cover all of the key stops and share the latest and greatest in new varieties and concepts. I’m getting excited! Hopefully some of you are also planning to make the trip. If so, be sure to check out our CALIFORNIA SPRING TRIALS website for all the details, including trial stops, lodging and restaurant picks.

If you’re not heading to Cali this year, you can follow us up the coast via our daily newsletter, packed with our takes on the varieties we see each day, as well as the videos you’ve come to know and love (at least I hope so …) Sign up to receive ACRES OF BUZZ to get daily reports.

Talk to you next week!

Please feel free to send your comments, constructive criticism and topic ideas to me at bcalkins@ballhort.com.

Bill Calkins

Editor - Tech On Demand

This email was received by you and 25,550 other fine subscribers!

If you're interested in advertising in Tech On Demand, contact Kim Brown ASAP and she'll hook you up.