12/1/2017

Moving Indoors

Joshua Craver & Roberto Lopez

In the final article of this four-part series, we’ll focus on the production of young plants in highly-controlled environments.

The desire to produce young plants in these environments stems from the fact that peak production of annual bedding plant seedlings (plugs) typically occurs during late winter and early spring. During this time, the daily light integral (DLI) is low due to short daylengths and reduced light intensities from cloud cover. As we discussed in the first article of this series, the target DLI for young plant production is 10 to 12 mol•m–2•d–1. However, in northern latitudes the ambient DLI is often as low as 1 to 5 mol•m–2•d–1 during this time of the year.

Reducing production time, shrink and producing high-quality plug trays can be difficult under these low-light conditions. Therefore, finding ways to increase the consistency, uniformity and quality of young plant production is highly desired.

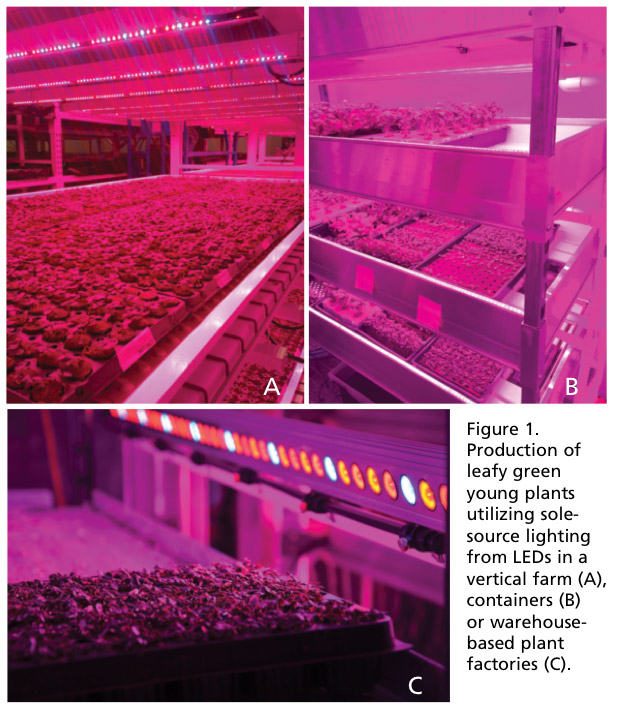

While we discussed greenhouse strategies of utilizing supplemental lighting to produce high-quality young plants in the previous articles, an alternative method is to move production indoors. Over the last five years, we’ve been investigating the effects of sole-source lighting (SSL) in indoor production systems. These systems could include multi-layer vertical, container or warehouse-based plant factories (Figure 1).

For those who may not be familiar with the term, SSL refers to indoor  production where plants receive no light from the sun. In other words, all of the light supplied to the plants comes from electric lamps, such as light-emitting diodes (LEDs). Unlike a greenhouse, this method of production can enable the grower to precisely control most, if not all, environmental parameters and, in turn, increase the uniformity and consistency of production.

production where plants receive no light from the sun. In other words, all of the light supplied to the plants comes from electric lamps, such as light-emitting diodes (LEDs). Unlike a greenhouse, this method of production can enable the grower to precisely control most, if not all, environmental parameters and, in turn, increase the uniformity and consistency of production.

However, there are significant costs associated with the installation and maintenance of these systems. While there’s still much work to be done regarding the economic feasibility of indoor young plant production, this article will focus on how we can optimize three environmental parameters using this technology to produce high-quality bedding plant seedlings. Specifically, this article will center on current research involving light intensity, light quality and carbon dioxide (CO2)

concentration.

Previous sole-source lighting research

Previous experiments our research group conducted have shown that indoor SSL is a viable method for the production of annual bedding plant seedlings. We previously reported that bedding plant seedlings produced under LED SSL with red:blue light ratios (%) of either 87:13 or 70:30 were often more compact and of higher quality than those produced under the same DLI in a greenhouse utilizing supplemental lighting from high-pressure sodium (HPS) lamps or LED fixtures.

Additionally, we evaluated how different light qualities and intensities further affected seedling quality under SSL conditions. Specifically, we looked at LED fixtures providing light ratios (%) of red:blue 87:13, red:far-red:blue 84:7:9 or red:green:blue 74:18:8 under light intensities of 105, 210 or 315 µmol•m–2•s–1. From this research, we determined that light intensity played the dominant role in dictating seedling quality and subsequent flowering, with bedding plant seedlings produced under higher light intensities being more compact and accumulating greater biomass (growth).

Ongoing sole-source lighting research

Currently, we’re investigating not only how light quality and light intensity affect bedding plant seedling production, but also how light interacts with other environmental factors. By understanding these interactions, we can develop a better understanding of how to optimize these SSL systems based on the entire production environment, not just light.

Within this approach, one area of interest is CO2 enrichment. Light and CO2 are both essential in the process of photosynthesis—the products of which are ultimately utilized in plant growth. As we know from our previous discussion, a sufficient DLI is essential to produce high-quality bedding plant seedlings. However, just as low light intensities can be limiting to plant growth, so can low CO2 concentrations.

Along these same lines, just as we found in previous studies that higher light intensities led to reduced production time and higher quality seedlings, we’re also interested to see if higher CO2 concentrations will lead to similar results. Therefore, the objective of our ongoing work is to optimize not only the light quality and intensity, but also the CO2 concentration for the production of high-quality bedding plant seedlings under SSL.

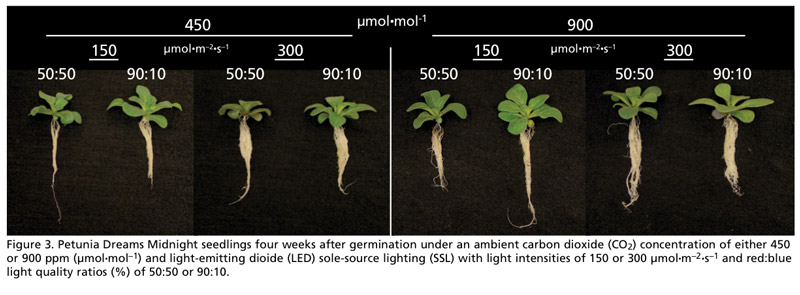

As with our previous SSL research, this study utilized walk-in growth chambers and multi-layered vertical production. In our initial study, LED arrays from Philips (GreenPower LED Research Modules) were used to establish light treatments consisting of two red:blue light ratios (%) of 50:50 or 90:10 and two light intensities of 150 or 300 µmol•m–2•s–1. In addition to the light treatments, we had two target CO2 concentrations of either 450 or 900 ppm (µmol•mol–1).

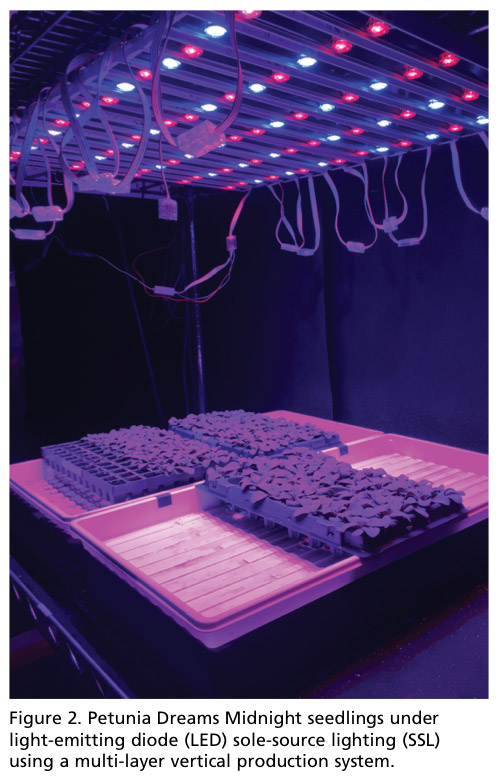

For reference, the ambient CO2 concentration outdoors is approximately 400 ppm, while the ambient indoor CO2 concentration in our facilities is roughly 450 ppm. Petunia x hybrida Dreams Midnight served as our model species for this study, and seeds were sown in both 128-cell and 288-cell plug trays (Figure 2).

For reference, the ambient CO2 concentration outdoors is approximately 400 ppm, while the ambient indoor CO2 concentration in our facilities is roughly 450 ppm. Petunia x hybrida Dreams Midnight served as our model species for this study, and seeds were sown in both 128-cell and 288-cell plug trays (Figure 2).

While the full study is still underway and we’re not yet able to share our complete findings, initial results indicate that elevated CO2 concentrations alongside higher light intensities may produce the highest quality seedlings (Figure 3). Therefore, elevated CO2 alongside increased light intensities may provide a promising approach to further increase seedling quality and reduce production time.

However, additional research is needed to determine the concentration of CO2 necessary to produce desired responses, the proper timing of CO2 injection and whether responses vary among species. We believe that SSL provides a promising alternative for the production of high-value young plants and we look forward to sharing more information and results in the future. GT

Joshua Craver is a Ph.D. candidate at Purdue University and Roberto G. Lopez is Assistant Professor and Controlled Environment/

Floriculture Extension Specialist in the Department of Horticulture at Michigan State University. The authors gratefully acknowledge Ball Horticultural Company for providing seed and Philips Lighting for funding.