Don’t Forget About Impatiens Downy Mildew!

Thanks to new breeding for Impatiens Downy Mildew (IDM) resistance, and more and more colors (and now doubles) available in new Impatiens walleriana highly-resistant varieties, greenhouses are once again full of this key shade bedding annual. But for your part, vigilance is still critical, because susceptible varieties are still in the market and the disease hasn’t gone away.

As our resident jack-of-all-trades, Tech On Demand expert Nick Flax once wrote, “As a group, downy mildew-causing pathogens are difficult to detect, they strike fast, they develop resistance to fungicides very easily, and managing outbreaks can be costly for you and your customers. Downy mildews are systemic (spread throughout infected hosts) and decline and eventual death of infected plants is almost always the result. By the time symptoms and signs appear, it’s too late, so preventative management is critical.”

Last week, I closed the newsletter with some coleus downy mildew tips. This week, I thought it would be a good idea to share resources to help you and your team stay on your front foot when it comes to IDM as we progress further into the spring 2025 season.

A lot of research has been done, and protocols for managing risk are pretty solid. We’ve created a bunch of content; here’s the laundry list:

Nick’s Tip of the Week: Phyto Happens! Then What?

Each week, I’ll work with my buddy Nick Flax, a technical services expert at Ball, to share a concern that’s come up during one of his numerous calls with growers across North America. This week, he’s discussing common causes of phytotoxicity and tips for avoiding it.

PROBLEM: When you see a brewing pest or disease problem, treatment with an appropriate insecticide/miticide or fungicide is typically a key step in your best management practices. However, sometimes phytotoxicity (adverse effects on plant growth, physiology or metabolism)—often called “burn” in general terms—occurs after an application and it’s not always clear as to why.

NICK’S TIP: Let me share a few common causes of phytotoxicity (phyto) and why this happens. There are many reasons that phyto may occur, and often it’s a perfect storm of multiple factors that ultimately cause it. If you’ve experienced a sudden onset of damage to your crops and can’t pinpoint the cause, consider the following:

Genus/Species Sensitivity: Some crops simply do not react well to certain active ingredients in IPM products or other components in the formulation, like carriers, emulsifiers, etc. As part of the EPA registration process, manufacturers screen a wide range of common ornamental genera for phyto.

-

Documented sensitivities are listed on the product label. Sometimes the label on the bottle or jug is difficult to read, so finding an electronic version on the manufacturer’s website is a good place to look if you cannot read the printed label.

-

A quick CTRL (or “command” for Apple users) + F search on a PDF version of the label is the quickest way to find this info. Generally, a search using the Latin genus or common name will bring you right to any notes regarding sensitivity of the crop in question to the product you want to apply.

-

Keep in mind: If a crop isn’t listed in a “sensitive species” section on the label, this does not guarantee phyto won’t occur. Always test a small group of plants when you apply a new IPM product or treat a new crop for the first time.

Inappropriate Tank Mixes: Time is a precious commodity for you and your team during spring and many of us like to save a few minutes whenever possible. This is especially true where pesticide applications are concerned, because sprays and drenches are often time-sensitive but also time-consuming.

-

When multiple products need to be applied to control spikes in pest and disease pressure, many growers will tank mix (combine multiple products) and apply them together.

-

However, not all products are chemically and/or physically compatible with each other. This can lead to phyto and severity can vary greatly, depending on the mix, dosage and other factors.

-

Some products mention specific pesticides with which they should not be combined. Oftentimes these are other products made by the same manufacturer, but it’s best to avoid tank-mixing with similar, off-brand chemistries, as well.

-

Addition of certain types of spray adjuvants in single-product applications can also cause phyto. For example, there are quite a few products we use in greenhouse ornamental production that specify they should not be used in junction with organosilicone surfactants. If you’re ever unsure whether it’s safe to add a new surfactant to a spray solution, consult with your chemical distributor or apply the mix to a few plants first to evaluate.

-

Here’s a link to an excellent University of Florida ARTICLE ON TANK MIXING BMPs. Be sure to review these steps before the next time you decide to tank-mix pesticides to minimize the chances of phyto or ineffective pesticide applications.

Drought Stress at the Time of Application: One for the first rules to follow when you apply insecticides, miticides, fungicides or plant growth regulators (PGRs) is to never apply when crops are too dry.

-

This is especially true for any product that is being applied to the root zone, or if foliage is slightly wilted before a spray. Drought stress lowers the water potential inside plant tissues. Water moves from high- to low-potential systems, so this makes it easier—almost too easy—for drought-stressed tissue to absorb pesticide spray or drench solution.

-

Rapid absorption due to lowered water potential can cause active ingredients, carriers or other parts of the formulation that might not normally be absorbed by plants to be absorbed rapidly by plant tissues. Excessive concentrations of these different components accumulate in cells, which can wreak havoc on cell function and cause phyto. This effect is like what you might see if the product you use was applied at too high a concentration under more normal conditions.

-

Avoid this is by ensuring that plants are well-watered at least 24 hours before you apply insecticide, miticide, fungicide or PGRs.

Next week’s focus will be on how to recover from phyto incidents, so stay tuned!

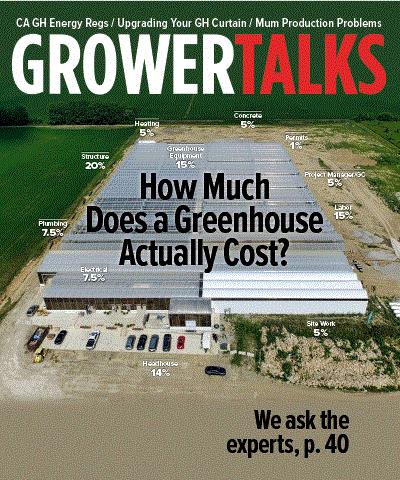

Article (plus a podcast): How Much Does a Greenhouse Cost?

If you didn’t get a chance to read GrowerTalks’ April cover story and you’re considering building greenhouses in the next few years, you definitely want to check it out or at least set the issue to the side and get to it as soon as spring crops are out the door.

In "How Much Does a Greenhouse Project Really Cost?", editor-in-chief (aka Bossman) Chris Beytes tackled the topic of greenhouse costs in a fresh way, talking to three greenhouse manufacturing experts—all with tons of experience executing projects of all sizes—and picked their collective brains on where the obvious costs lie, as well as all of the things that might not be considered when you start budgeting. Many “pro tips” are also included in the article, including mistakes not to make and thoughts on planning ahead for future expansion.

As Chris writes:

You’ve acquired a piece of land and set aside some cash and arranged financing for your very first greenhouse and you’re ready to invest $500,000. You start shopping for structures, thinking that at roughly $10 per sq. ft. (a figure you got from the grower down the street), you can afford as much as an acre (about 44,000 sq. ft.) of greenhouse. Wow! A nice size for starting out!

But wait … haven’t you forgotten something? Or maybe a bunch of things? Like permits, engineering, site prep, gravel or asphalt, concrete, a well, plumbing, electrical, heating, environmental controls, energy curtains, a headhouse … even the labor to build it all?

The answers to these questions and more are presented in HOW MUCH DOES A GREENHOUSE PROJECT REALLY COST?

Spoiler alert—here’s how the costs are broken down in the article.

-

Greenhouse structure: 20%

-

Project manager/GC: 5%

-

Construction labor: 15%

-

Headhouse: 14%

-

Permits/engineering/soil tests, etc.: 1%

-

Site work: 5%

-

Concrete: 5%

-

Electrical: 7.5%

-

Irrigation/plumbing: 7.5%

-

Heating: 5%

-

Equipment/growing systems: 15%

I thought this article was so good that I decided to record it as a Tech On Demand Audio File podcast. So, if you don’t have time to read it now, go ahead and pop in your Air Pods and give it a listen on SPOTIFY, APPLE PODCASTS, YOUTUBE or most of the other popular apps—it’ll only take 10 minutes.

Avoiding Iron & Manganese Toxicity

Ball Seed Technical Services specialist (and frequent Tech On Demand contributor) Josh Henry recently shared some important technical training tips covering iron (Fe) and manganese (Mn) toxicity because these issues aren’t too common with most crops and there are a few that can be prone to such disorders—like geraniums, New Guineas, pentas and marigolds.

Here’s a summary of what Josh covered in HIS LATEST TECH TRAINING DOCUMENT. Click the link for the full two-page whitepaper with tips on the front and a more-detailed breakdown on page two.

Understand your inputs—crops, substrate, water quality and fertilizer selection can all have an impact when dealing with Fe and Mn toxicity.

Monitor substrate pH and scout for symptoms—keeping sensitive crops at a pH between 5.8 and 6.5 will help prevent issues. And watch for symptoms like lower leaf margin bronzing or black spots.

Use corrective procedures to raise pH—flowable lime at 1 to 2 quarts per 100 gallons or potassium bicarbonate at 2 pounds per 100 gallons will increase your pH. Just make sure you rinse these products off foliage to prevent burn. And if using potassium bicarbonate, leach pots out one day after application.

Be sure to download the PDF for much more on each of these tips. It’s the first tech training document on the list.

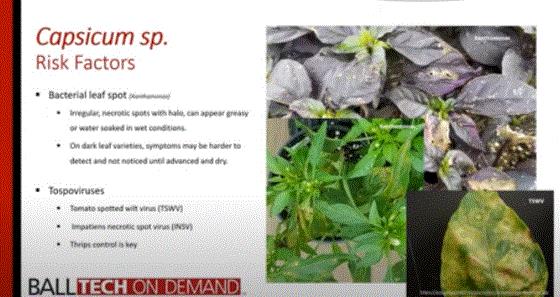

Ornamental Pepper Insect & Disease Risks

I can’t believe I’m about to write about a fall crop! But hey, the goal is always to prepare you and your teams to tackle problems if and when they come up, and part of the trick is staying ahead of common issues. Ornamental peppers are popular fall crops and consumer demand is always high, so let’s ease into fall tips with some info on risks associated with peppers.

If you’re producing a crop of fun and decorative peppers this year, you do need to be aware of some common challenges. In one of our “at-risk crop” videos, I went through RISKS ASSOCIATED WITH PEPPER CROPS with Dr. Todd Cavins, one of our Tech On Demand experts at PanAmerican Seed. The discussion covered bacterial leaf spot and tospoviruses with plenty of information about these potential challenges, as well as proven strategies for control. We also put together a HANDY DOCUMENT with more thorough information on Bacterial Leaf Spot on ornamental peppers that guides you through the stages of plug production and growing on to finish so you end up with a clean crop.

Photo: University of New Hampshire

Another common problem growers experience with peppers is broad mites. Check out the photo above—you don’t see the mites themselves, but the damage is clear. Pesky broad mites can wreak havoc on this crop and most of the time the bugs can only be seen with microscopes found in diagnostic labs and not with the tools we keep in our pocket as growers. Be aware, not all miticides control these bad guys, so be sure to read the labels on your control products so you don’t waste time and money. And consider biocontrols like predatory mites early in your crop cycle if you’ve had issues with broad mites on peppers in the past.

Finish Line … New from PW

Last week, half of the Ball Publishing Bobblehead crew (Chris and Jen) journeyed to Four Star Greenhouse in Michigan for the annual Proven Winners new variety open house. Of course, they captured as much as possible in 4K video glory. Check out these five videos!

NEW ANNUALS FROM PROVEN WINNERS FOR 2026 AND BEYOND!

Chris is joined by expert Tim Anderson for a tour of all the pretty new annuals from Proven Winners, including an all-new agastache series the pollinators will love, a gorgeous pink Supertunia Vista called Cool Jazz and a bright red Jamesbrittania aptly called Lava Flow.

WALTERS GARDENS PERENNIALS FOR 2026

Walters Gardens' Christa Steenwyk takes editor Jen Zurko on a tour of new Proven Winners perennials for 2026 and beyond, including several genera that are brand new for them.

NEW BLACK AND CRÈME (BRULEE) CALADIUMS

Check out the new Heart to Heart caladiums from Proven Winners: Midnight Oil and Creme Brulee.

HOLLYWOOD HIBISCUS

Proven Winners' Tim Anderson tells growers how they can get Hollywood hibiscus as liners and Quick-Turn prefinished plants. They take as little as 12-14 weeks to finish!

THE NEWEST IN SUSTAINABLE POTS AND IRRIGATION

Marshall Dirks from Proven Winners tells Jen Zurko about the latest generation of Eco-Grande zero-plastic pots and the newest solution for efficient watering of your containers.

Talk to you next week!

Please feel free to send your comments, constructive criticism and topic ideas to me at bcalkins@ballhort.com.

Bill Calkins

Editor - Tech On Demand

This email was received by you and 25,614 other fine subscribers!

If you're interested in advertising in Tech On Demand, contact Kim Brown ASAP and she'll hook you up.