NEW VIDEO! Anemone Gemstone Recipe for Success

Last week, I had the opportunity to catch up with a couple of cut flower experts to discuss a popular crop that’s now available in a new form that offers tons of benefits for growers and flower farmers: seed anenomes.

Now, anemones are not new by any means; in fact they’re quite old and were written about in ancient Greece. But traditionally, they’ve been produced from corms planted in fall and harvested in spring.

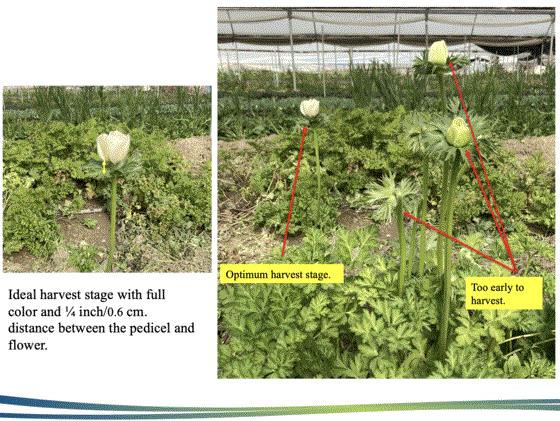

When Sakata introduced anemone Gemstone, an F1 from seed, a few years ago, it was a major breakthrough and quickly generated attention from cut flower growers. I was excited to talk to Bob Croft, Sakata’s product technical manager, and Joan Mazat, Ball’s cut flower business manager, to learn more about Gemstone. They shared tips and tricks for selecting and producing top-quality crops, explaining how to position Gemstone in a cut flower program, and why it’s such a beautiful, popular flower. Oh, yeah, I also learned a new word: pedicel.

Check out GROWING F1 ANEMONE GEMSTONE FROM SEED: EVERYTHING YOU NEED TO KNOW.

Bob has plenty of experience with this F1 seed series. He takes viewers and listeners through crop production and finishing—from germination to transplant and on to postharvest care and even why not to put anemone into vases with daffodils. He helps cut flower farmers manage all factors of plant growth (light, water, nutrition, temperature and gas exchange), offers strategies for controlling pests and diseases, and explains the benefits of starting anemone from seeds versus corms.

This anemone Gemstone tutorial is also available in audio format in case you want to listen while taking care of other tasks. Be sure to subscribe to the Tech On Demand podcast on your favorite app so you never miss an episode. And this winter, why not jump back into the archives and get caught up—there are more than 145 episodes as of today.

TECH ON DEMAND ON SPOTIFY

TECH ON DEMAND ON APPLE PODCASTS

Nick’s Tip of the Week: Injector Maintenance Deep Dive

Each week, I’ll work with my buddy Nick Flax, a technical services expert at Ball, to share a concern that’s come up during one of his numerous calls with growers across North America. This week, some of his fellow Technical Services members have been chatting about videos we have planned for 2025 to help you tackle common greenhouse tasks. Injector maintenance was one topic that came up, and it seemed like a good topic to address in the newsletter for those of you who already have spring production prep on your minds. If you don’t, hang onto this and add it to your to-do list.

PROBLEM: Injectors are the backbone of some of our most critical growing tasks. From fertilizer applications and correcting deficiencies with amendments to applying insecticides and fungicides, injectors are daily workhorses that shouldn’t be neglected. If you haven’t given your injector some TLC in recent months, check your calibration and perform routine maintenance now—or at least before spring crops start arriving.

Photo: Tina Smith, UMass Extension

NICK’S TIP: Over time and with frequent use, your injector's calibration can “drift.” This means you may be over or underfeeding your crops, or not applying insecticide or fungicide drenches at the correct rate. A calibration check is the easiest way to make sure your injector is hitting its mark. To do this, you’ll need the injector (of course), an EC meter, your favorite fertilizer and a cup or beaker for sample collection.

-

First, run your clear water for a couple of minutes and collect a sample in a clean cup. Test your raw water’s EC and write the value down (for example, raw water EC is 0.41 mS/cm).

-

Next, find the label on your fertilizer bag, select your desired feed rate and injection ratio (ex. 200 ppm N at 1:100), and find the corresponding EC value that you should be getting at the end of your hose (for instance, if the label says at 200 ppm N 1:100, EC should be 1.29 mS/cm).

-

Add the raw water and fertilizer target EC values (like … 1.29 + 0.41 = 1.70 mS/cm).

Next, set your injector ratio to the prescribed setting. In this case, adjust to 1:100. Run your injector for a minute or two, allowing fertilizer stock solution to fully enter the injection stream. Collect a sample from your hose and test the solution’s EC.

-

If the EC value is close to what your math says it should be, your injector is good to go. Repeat this quick check several times throughout the season and adjust as follows:

-

If the EC value is too low, reduce the denominator of your injector ratio. (ex. if your target EC is 1.70 mS/cm at 1:100 but the test reads 1.50 mS/cm, change the ratio to about 1:90, run the injector for about one minute, collect a fresh sample and retest.

-

If the EC value coming out of your injector is too high, do the opposite and increase the denominator (An example would be1.90 mS/cm when it should be 1.70 mS/cm).

-

Retest and readjust until the EC of the solution coming out of your hose is close to what it should be, per the fertilizer label and your quick math.

If calibration adjustments to your injector are large (for example, you need to set it to 1:75 to achieve the target EC that your fertilizer bag says you should achieve at 1:100), it’s time to service your injector. For many piston-driven injectors, manufacturers sell rebuild kits that include new O-rings, diaphragms and other parts that wear out over time and need to be replaced. Always follow manufacturer recommendations for self-service repairs and rebuilds, and make sure that you do not void any warranties that may be active for your injectors.

NOTE: For computerized and other digitally-driven injector systems, contact the manufacturer and schedule a service appointment ASAP. Parts and labor availability always get tight leading into spring, so don’t wait until the week before major planting starts in your operation to get your system tuned up.

Two Awesome Educational Opportunities!

I heard from Heidi Lindberg at Michigan State University Extension that growers have until January 1, 2025, to register for this year’s College of Knowledge online courses and the Plant Health Professional Certificate Program. Before things get crazy for the holidays, REGISTER ASAP at the links below:

COLLEGE OF KNOWLEDGE COURSES

PLANT HEALTH PROFESSIONAL CERTIFICATE PROGRAM

This year’s online courses include Abiotic Disorders of Greenhouse Crops, Greenhouse and Horticultural Lighting, Biological Control for Greenhouse Growers and Floriculture Root Zone Management—and are available in English and Spanish. The content is spot-on with what greenhouse professionals are talking about these days and the course content is perfect for new production team members and growers who want to learn more about different areas of crop and pest management. Full course details are available on the website.

Participants have three months (December 1, 2024, to March 15, 2025) to complete the online courses with pre-tests and final exams to determine skill retention. The cost is super-reasonable—just $129 per course!

The Plant Health Professional Certificate Program is a joint program by MSU Extension and the University of Florida, and participating growers can earn their certificate by taking online courses. It’s a training curriculum for greenhouse professionals already working in the industry and requires participants to pass five of six courses taught by university faculty. Full details can be found at the link above.

Sanitation Topics for Your Next Staff Meeting

As you prepare for spring 2025 production, here are a few tricks of the trade to share with your staff. In your next team meeting, consider bringing one of these tips to the table to start a discussion:

Stripes on your bench? If you see irregular stripes within your production zones, it's irrigation tune-up time. In the photo, you’ll see the problem quickly. In this case, begonias are the crop in question. Unfortunately, they’re among the most sensitive crops to uneven irrigation. Take a look at your nozzles and ask yourself, “Are they clean or worn out?” It might be time to replace them before heading into spring production. Uniformity of irrigation can have dramatic impacts on even (or uneven) plant growth.

Are your foot baths and tire baths ready for next season? Are they deep enough and changed regularly? To keep diseases out of your operation you need to make sure that wheels and feet are thoroughly covered with disinfectant. Most disinfectants work by contact. If you don’t have active chemical in contact with the disease, there’s no kill. Another challenge is once all the chemical has reacted with organic matter it’s no longer completely effective in control disease. In high traffic baths, changing the solution two times each day is recommended to ensure that there’s active disinfectant in the bath.

Do you always clean your spraying tank and hoses after spraying? If not, you’re not alone. Unfortunately, not cleaning your tank and hose after spraying creates more risk. You can easily run into phytotoxicity, reduced effectiveness of spray applications and unexpected results from the chemicals you spray, especially PGRs. Always clean your tools, and do so in an environmentally-responsible way.

Tech Tip: Phyto on Viola

Check out this quick cultural and technical tip I pulled from our Tech On Demand database. Seeing real-world production challenges and reading solutions and advice can only help fill your toolbox and arm you with information for if and when you see similar issues in your own production. We collect dozens (maybe hundreds) of photos each month and are building quite a database of tech tips. It’s easy for me to jump in and snag a photo and how we responded to problem.

Here’s a perfect example: A grower saw this in his spring viola production and was concerned about spray damage. Here’s the reply and some words of advice:

In the photo, the new flowers are free of spots. This indicates the old flowers had been damaged during a chemical (fungicide) application earlier in production, when the new flowers were still in bud stage. Be careful spraying fungicides on open flowers. Always test, or avoid spraying on open flowers.

Finish Line ... Thankful!

It occurred to me that this is the final Tech On Demand e-news until after I stuff myself with turkey and mashed potatoes next Thursday. It is this week every year when I like to pontificate on something related to Thanksgiving to close the newsletter, because it’s my absolute favorite holiday and comes with an opportunity to reflect.

The noun thanksgiving is defined (by Mr. Oxford) as “the expression of gratitude, especially to God” and I want to share a few ways to practice gratitude this holiday season. Gratitude is definitely personal so I’ll keep these ideas pretty general, but hopefully they spur some thoughts and ideas about ways to think about others more than ourselves.

Spend quality time with someone. We live in a world filled with distractions, and even face-to-face conversations these days tend to end with glances at phones. Setting aside time for others without distraction benefits both parties.

Show generosity. There’s no lack of negativity out there if you’re not focused on staying positive, and simple demonstrations of generosity and kindness mean more than ever before. Gestures of kindness show people you’re thinking about them.

Practice patience. This is a big one. It’s easy to fly off the handle and not give folks the benefit of the doubt. I remind myself (and my kids) that most people are white-knuckling it through life and we should pause and breathe before reacting. You never know what the other person is dealing with. Try to not be in a hurry this season—it’ll be so much more enjoyable.

Plan a day of service. Just about every organization that works with underserved people is in full gear during the holidays. It should be no problem finding an opportunity to serve others and give back. Drag your family along. No one has ever spent a day helping others and not gained new perspective and felt they made a difference.

Okay … I hope that didn’t sound lecture-y. I feel like it did but that wasn’t the intent. Until next week, stay grateful!

Please feel free to send your comments, constructive criticism and topic ideas to me at bcalkins@ballhort.com.

Bill Calkins

Editor - Tech On Demand

This email was received by you and 25,742 other fine subscribers!

If you're interested in advertising in Tech On Demand, contact Kim Brown ASAP and she'll hook you up.