3/1/2024

Under Pressure

Broch Martindale

With many of you in the middle of another growing season, it’s important that you keep last season’s pest challenges top of mind and use those learnings to help you control future pest pressures. Last season, aphids were the biggest challenge for many. While aphids aren’t particularly difficult to control, the early arrival and persistence made these small sap-sucking insects especially challenging.

When controlling any pest, a program approach can go a long way in reducing pest pressures. Your program should be regularly reviewed and updated to apply learnings from previous growing seasons to avoid insecticide resistance.

If you’re new to integrated pest management programs or looking to improve an existing program, read on for some simple ways to ensure you’re getting the most from your efforts.

Start with training

When I’m looking to improve my IPM program on my cut flower and perennial farm, training is the first place I start. That’s because training can be easily overlooked, especially if you’ve had to hire extra hands during especially busy periods. Training also ensures everyone knows and can identify the pests that affect your facility.

Additionally, it’s important to have a communication plan when pests are identified and train your employees on the proper steps. This ensures the needed information about the location, the crop and the pest is communicated promptly and accurately to decision makers with the information they need to act accordingly.

Don’t be afraid to incentivize or turn scouting into a game and reward those who find pests even if it’s not their primary role. The goal here is to create a work culture where everyone is responsible for controlling pests in your facility.

Don’t be afraid to incentivize or turn scouting into a game and reward those who find pests even if it’s not their primary role. The goal here is to create a work culture where everyone is responsible for controlling pests in your facility.

Create incoming material-handling processes

Proper sanitation is essential when preventing the risk of insect and disease outbreaks in your facility. Pests and diseases are often introduced to production facilities by incoming plant material. All incoming plugs and liners should be placed in a quarantine area that’s regularly monitored and, if necessary, treated for pests and diseases before being moved into the production area.

Often, I’ve observed growers placing this material near other material produced in the facility, putting both groups of plants at risk. The last several years have shown us some quarantinable diseases that have caught some growers unnecessarily quarantining plants in the same area as the infected plants.

Remember: When building quarantine areas, it’s important not to place them in high-traffic areas to limit the risk of spreading pests and diseases to other facility areas.

The importance of a rotation

Repeated use of the same products with the same mode of action (MoA) over an extended period will create pest populations that are less susceptible to those products. To delay or prevent pesticide resistance, growers should develop a rotation of products with a minimum of four and, ideally, six or more different MoA groups. MoA classifications are published by the Insecticide Resistance Action Committee (IRAC) to prolong the effectiveness of insecticides and miticides. (For more information on IRAC and MoA, visit irac-online.org/mode-of-action.)

Pesticide selection is an important task of every grower and your rotation should be evaluated at the end of every season. For many, growing a great crop means following a recipe that’s been refined for years. Controlling pests is no different; it’s all about selecting the right product from the start, which will help make your job easier.

When selecting pesticides, it’s important to consider timing, plant safety and pest pressure to ensure success when using pesticides to control insects and diseases in your facility. However, proper pesticide stewardship is critical to avoid problems, such as phytotoxicity and resistance. Most importantly—read the label of all pesticides before use and follow label directions.

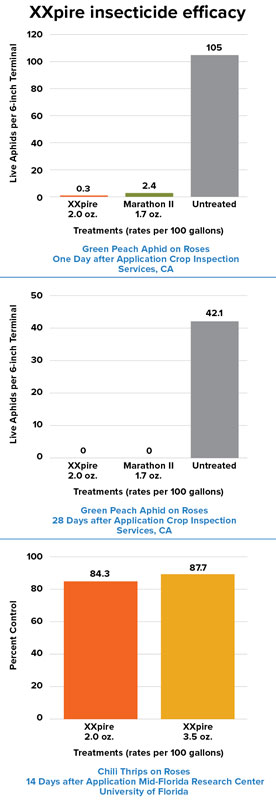

For many growers, XXpire insecticide is the answer

XXpire insecticide contains two ingredients that control a broad spectrum of insect pests on ornamental plants. XXpire insecticide poses minimal phytotoxic risk to plants, is less disruptive to beneficials and controls seven of the top 10 insect pests on ornamentals.

XXpire insecticide is composed of two proprietary active ingredients from Corteva Agriscience, each with a unique MoA. One component, sulfoxaflor, provides outstanding control of sap-feeding insect pests, including aphids and whiteflies, and has been categorized by IRAC as a Subgroup 4C insecticide. The other component is spinetoram, which provides control of chewing pests and has been categorized by IRAC as a Group 5 insecticide.

XXpire insecticide controls most pests and suppresses spider mites on ornamental plants in nurseries and greenhouses.

Key takeaways of XXpire insecticide include:

● Two active ingredients: sulfoxaflor and spinetoram

● Two modes of action

● Effective on more than 39 insect and mite pests

● Controls seven of the top 10 insect pests on ornamentals and suppresses spider mites

● Up to one month of residual control, depending on the pest

● Less disruptive to beneficial insects

● Minimal phytotoxic risk to plants—no plant injury observed on more than 300 plants tested

● No visible spray residue on flowers and leaves after application

● Can be applied in both greenhouse and outdoor production facilities

● Low odor

Proven safety from seedling to shipping day

Ornamental safety is a critical issue for all insecticides. Corteva Agriscience understands the importance of insecticide and herbicide safety and has tested XXpire insecticide against more than 300 types of plants, which has shown an excellent margin of safety in all cases.

Please be aware that ornamentals can respond differently under different application conditions, such as temperature, soil moisture and relative humidity. I recommend testing XXpire insecticide on a small sample of plants to ensure injury will not occur under your specific crop and application conditions.

Adding adjuvants to sprays of XXpire insecticide may improve initial spray deposits, plant coverage, penetration into waxy leaf surfaces, redistribution and weatherability. Select adjuvants that are recommended and registered for your specific use pattern and follow their use directions.

Improved control of whiteflies and spider mites has been observed in research trials when organo-silicone adjuvants have been used with XXpire insecticide. We recommend testing XXpire insecticide with any adjuvants on a small sample of plants to ensure injury will not occur under your specific crop and application conditions. When using adjuvants, always conduct a jar test to determine the compatibility of the various components in the spray mixture. Crop safety should further be evaluated in a small area of the crop whenever there’s a significant change in spray mixture ingredients or source of water for the spray mixture. GT

Discover how XXpire insecticide can help you control more than 39 insects while reducing the likelihood of resistance with two modes of action by visiting Corteva.us/XXpireGT.

Broch Martindale is National Nursery & Greenhouse Strategic AccountManager for Corteva.

™ ® Trademarks of Corteva Agriscience and its affiliated companies. XXpire® is not registered for sale or use in all states. Contact your state pesticide regulatory agency to determine if a product is registered for sale or use in your state. Consult the label before purchase or use for full details. Always read and follow label directions.