1/1/2023

Learning Curves & Data Curves

Bill Calkins

Using vapor pressure deficit (VPD) to manage transpiration and water loss is a technique employed by greenhouse growers around the world. The goal is to accurately manipulate the environment around your plants to achieve the best results in terms of growth and quality. There are different ways to do this—single unit controls or environmental control systems—with the impact on plants being similar.

Research over many years has proven that VPD is a better way to measure and predict soil evaporation and plant transpiration than relative humidity (RH), and growers have learned how to use VPD quite effectively. But, like most greenhouse processes, VPD isn’t a one-size-fits-all tactic and the nuances are seemingly endless, from species and variety to crop stage and unique production goals.

University researchers and technical experts across the industry have spent a lot of time and resources learning the impacts of VPD, and the amount of data collected has led to many breakthroughs and published best practices.

We spoke with one such expert, Dr. Will Healy, about what he and a team of researchers discovered during a long career at Ball Horticultural Company when digging into environmental management topics such as VPD.

Definitions

Let’s start with some terms because this content can be complex if you don’t understand the basic terminology.

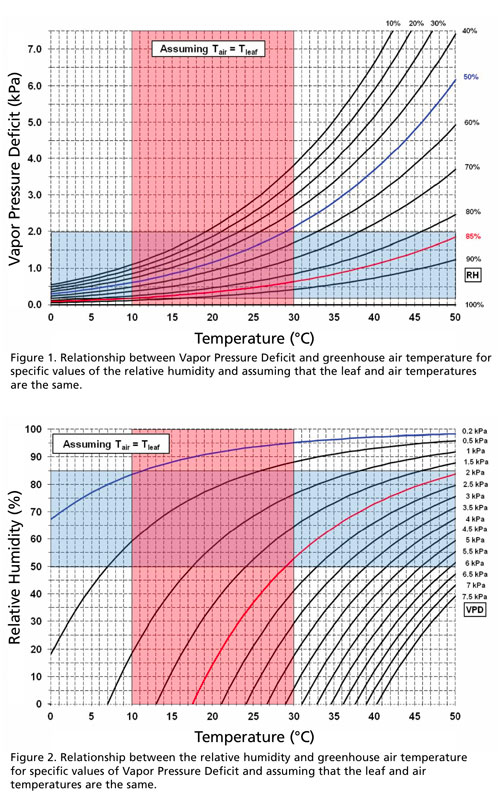

Will said vapor pressure deficit is the measurement of the absolute difference in the amount of water vapor in the air versus how much water can be held by the plant and soil at saturation—adjusted for temperature. Growers use the accumulated VPD over time to determine when enough water has been lost from the plant and soil to trigger misting or irrigation events. VPD is different than “relative humidity,” which, at a specific temperature, measures the relative difference in the amount of water in the air compared to the amount of water in the air at saturation. Here are some terms that describe moisture in different ways:

• Evapotranspiration: Water loss from plants and soil

• Vapor pressure: The point where water changes from a liquid to a gas

• Dew point (fog): At a given temperature, the point at which the air can’t hold any more water and starts to condense into visible droplets

Why use VPD?

Millions of crops have been grown successfully without ever taking a VPD measurement. However, Will explains there are many positive impacts that are realized when incorporating VPD in your greenhouse, from propagation to production to finishing. Furthermore, the benefits of VPD management on insect and disease control can be dramatic and help reduce chemical use, labor and ultimately result in higher-quality crops across the board. In a nutshell, you and your team will water based on your crops’ specific water loss versus dates on a calendar. VPD allows for tremendous accuracy.

“In propagation, using VPD to maintain proper URC hydration and turgidity during rooting helps get crops off to a strong start. Reducing soil moisture as roots begin to develop is another critical benefit,” Will said. “Moving into the main production stage, using VPD to more accurately manage and control irrigation results in faster growth, lower disease and insect pressure, as well as controlled stem elongation.”

When it comes to insect and disease management, he says employing VPD can help reduce fungal spore germination and spread, not to mention the spread of bacteria. Accurately measuring and managing VPD can have a tremendous impact on pests and diseases in young plant production, Will says.

“If crops are too dry, spider mites can explode in your greenhouse, but if they’re too wet, diseases can rapidly occur and spread.” For example, low VPD can result in increased Botrytis risk, among others.

Treating pests and diseases often requires spraying, which in turn adds moisture to the environment and messes up optimal VPD, he adds. Plant disease runs rampant when foliage is wet and the overall greenhouse environment is moist, so maintaining the proper VPD can go a long way in reducing risk.

VPD and young plants

When cuttings arrive at a greenhouse, they tend to be dehydrated due to unfriendly shipping environments and general moisture loss from dry boxes and temperature fluctuations. Using VPD control to bring them back up to an optimal hydration level can be the difference between a strong, healthy crop and one you constantly have to battle throughout production.

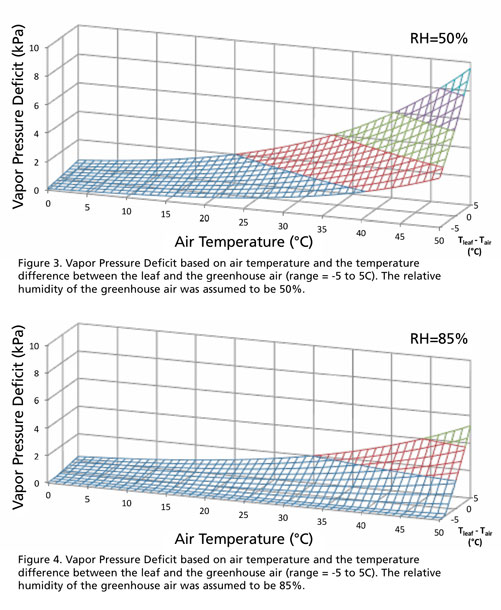

According to Will, inaccurate temperature control during transport and heating in the box will trigger an intra-URC temperature increase (inside the plant). Plant respiration rates are greatly impacted by temperature and as temperatures go up, VPD increases. Then you might put them in a cooler overnight to increase turgidity before sticking, but Will reminds us that coolers are dry (high VPD) by nature, which also must be considered.

Once cuttings are stuck and moved into propagation zones, VPD becomes an excellent tool. Your environment is probably quite humid, and when the air is saturated, VPD is zero, and water loss from the plants and soil is minimal. Will suggests early in propagation the VPD measurement should be less than 1 or even less than 0.5 so plants will become fully turgid. When using VPD instead of a timer in propagation, you can reduce the frequency of misting, which leads to less nutrient leaching and algae growth.

Once cuttings are stuck and moved into propagation zones, VPD becomes an excellent tool. Your environment is probably quite humid, and when the air is saturated, VPD is zero, and water loss from the plants and soil is minimal. Will suggests early in propagation the VPD measurement should be less than 1 or even less than 0.5 so plants will become fully turgid. When using VPD instead of a timer in propagation, you can reduce the frequency of misting, which leads to less nutrient leaching and algae growth.

A great deal of research has been done to determine VPD requirements for rooting and propagating specific crops because we all know some species and varieties root quickly, while others are slow rooters. Your VPD/irrigation triggers should be adjusted accordingly to maximize propagation quality.

Will explains that quick-rooting crops like impatiens require a shorter period at a low VPD with a higher VPD after three to five days to help dry the soil out and force rooting. Compare impatiens to slower-rooters like lavender, which benefit from a longer period at a low VPD to prevent the cutting from dehydrating before roots begin to develop.

One result of this crop research is an ability to track and employ growth curves, charts that show the specific curve to follow when increasing VPD as rooting stages progress. For fast-rooting crops, the increase in the VPD is very steep, like the proverbial hockey stick, and for slow-rooting varieties, the increase is much more gradual. Having a file with these curves will offer an excellent reference point for future seasons.

Moving to stage two, when the callus begins to form at about days four to seven, Will suggests continuing to increase the VPD trigger point above 0.5. As roots begin to develop in stage three, this is where your VPD strategy changes, he says. “From about day seven to 21, VPD should trigger at 2.0 or above.”

Remember: the higher the VPD measurement, the drier the plant and soil. Maintaining optimum wet-dry cycles is the key to a healthy greenhouse environment. As your roots grow, you’ll want to work with your team to make sure the plants are irrigated up to a level 4, before drying down to a level 2 to promote good root development.

Modern controls take VPD measurements every minute or more, creating graphs that allow you to “scientifically” determine the accumulation of VPD units and know precisely when to irrigate. GT