11/1/2022

Best Management Practices for Unrooted Cuttings

Julie Martens Forney

Having someone who can help you weather storms and solve problems is priceless. If you’re growing commercially, you actually have that kind of invaluable partner: the American Floral Endowment (AFE). Funded by growers for growers for over 60 years, this organization helps determine effective, reliable solutions to real world production problems—things like pest and disease control, cost-effective crop lighting, and improving cut flower and plant longevity.

One problem that AFE has been unraveling is handling and propagating unrooted cuttings (URCs). Dr. John Dole, North Carolina State University, and Dr. Jim Faust, Clemson University, helped lead studies on unrooted cuttings.

With current supply chain challenges, handling URCs properly is vital to successfully sticking, rooting and growing a uniform, ready-for-market crop.

Make sanitation your top priority

Prior to cutting arrival, the best thing you can do is sanitation.

“Clean the cooler and then look at traffic flow, at where cuttings will be staged,” John says. Sanitize benches—top and bottom. “The area beneath benches is easy to overlook, but weeds under a bench can have insects and diseases that can affect your cuttings.”

Pictured: Post-storage dips improve cutting turgidity (bottom photo), which makes sticking tiny cuttings like these New Guinea impatiens much easier. Dips also improve rooting.

Pictured: Post-storage dips improve cutting turgidity (bottom photo), which makes sticking tiny cuttings like these New Guinea impatiens much easier. Dips also improve rooting.

Trays and equipment need to be sanitized, along with employee clothing and hands.

“Make sure everything is clean,” he adds. “This is something we typically do at the beginning of propagation season, but you should also look at all of these things periodically during the season. It’s not unheard of that problems crop up because of not paying attention to sanitation as things move into the heat of propagation season.”

Train your staff

“I can’t overstate the importance of training your team on how to handle unrooted cuttings,” John says. “Training needs to be ongoing—it requires commitment. We’ve all been there—we had a training, but if we don’t repeat the training, we can tend to drift off the mark.”

John specifically urges growers to train their crew in these areas related to handling and propagating URCs: unboxing, sorting, assessing cutting quality, processing, prioritizing and sticking.

“Of course, we also need to train on scouting for insects and diseases,” he adds.

Four choices for cuttings

To maximize URC performance, the top issue to consider is temperature versus time. This is the key to handling them successfully. When URCs arrive, you have four options:

• Stick immediately

• Hold cuttings in a cooler for < 24 hours

• Hold cuttings on a propagation bench for < 24 hours

• Store cuttings for > 24 hours

Knowing when to choose each option is vital to your success with URCs. Immediately stick any plants that are poor shippers or that don’t hold well in storage. This includes coleus, crossandra, euphorbia hybrids, lantana, portulaca and sweet potato hybrids. You also want to prioritize sticking any difficult-to-root species or cultivars, such as thunbergia or lavender.

“Pull those URCs out of the shipment and propagate as soon as possible,” John says.

If you hold cuttings in a cooler for less than 24 hours, a temperature of 50F (10C) works for nearly every plant type. For cold-tolerant species like geranium and petunias, 35 to 40F (1.6 to 4C) brings benefits—you can hold things longer at a lower temperature and the quality keeps better. A few tropical plants need a warmer 55F (12C) cooler; these plants are actually damaged at 50F.

John suggests that when you unpack boxes, “check plant temperatures with an IR gun or temperature probe. If it’s over 70F (21C), remove the cuttings from box so they’ll cool quicker. Spread cuttings out on a tray, put them into coolers and get the heat out. A warm box is not going to cool down fast enough. Insulated boxes keep cuttings cool in shipping, but they also trap heat.

Use this same method of unpacking URCs and getting them into the cooler if temperature upon arrival is between 60F (15.5C) and 70F, if the shipment has been delayed or if you plan to stick cuttings the next day.

“What we really love to see is when that temperature is 50 to 60F,” John says. “If that’s the case, simply stick the boxes into your cooler.”

If you opt to hold URCs on the propagation bench so light can jumpstart photosynthesis and recharge cuttings with some carbohydrates, make sure they’re not stressed.

“During shipping, cuttings have been in a box with no light, so this method can help. Just be sure to turn off the bottom heat and turn on the mist,” John explains.

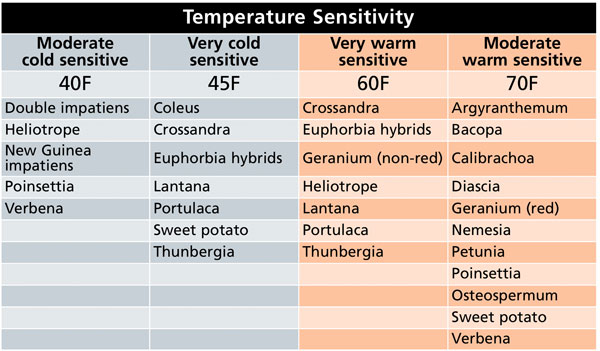

Table: Know the temperature sensitivity of the crops you propagate. Use this guide to help you store cuttings properly.

Table: Know the temperature sensitivity of the crops you propagate. Use this guide to help you store cuttings properly.

The last option, holding cuttings more than 24 hours, is simply not recommended.

“Some species store well if temperature control is excellent,” John stresses. “But in the middle of the season, temperatures in the cooler can shift a bit because you’ve been putting a lot of plant material in there. That’s not a good situation.”

Some species that do store well if cooler temperatures are spot on include argyranthemum, chrysanthemum, New Guinea impatiens, osteospermum and petunias.

Best sticking practices

Only take the number of cuttings into the greenhouse that can be stuck within an hour.

“At this point, cuttings are near the end of their storage time, so they’re going to have a low carbohydrate status. That means they’re even more sensitive to temperature,” John explains.

As cuttings sit on the bench waiting to be stuck, keep them out of direct sunlight. They should be loose on trays, not sitting in bags that can heat up. You can even put a little shade cloth or Reemay on them to help keep the temperature down.

“Crew leaders should be aware of upcoming work breaks, too,” John adds. “Don’t let cuttings sit out while the crew is on break.”

Delayed shipments: Stick or replace?

When delays are excessive, cuttings experience moisture loss, low carbohydrates and possible pathogen development. In some species, ethylene sensitivity increases as carbohydrate levels drop. If cuttings are stressed due to shipping delays, you might see dropping leaves, leaf yellowing or death, dead growing tips or disease.

Some signs, like slow and uneven rooting, won’t show right away.

“Those are some of the worst problems in some ways,” John says. “Cuttings won’t root and grow uniformly, which will mess up production schedules.”

At this point, the question becomes: Do you stick a low-quality cutting and risk poor quality or request a credit and replace the cuttings? Either way, you risk missing production schedules on crops, which is a big deal.

“As we pondered this question, we came up with another one: Can we replace the water cuttings have lost prior to stick?” John shares. “Is it possible to rejuvenate cuttings and shift them from low quality to high quality?”

His team researched recovery solutions that could be applied to cuttings to try and recover quality when shipments are delayed.

“We realized that if we’re trying to treat cuttings with water, we could easily add other compounds, including spray adjuvants, fungicides, sugars and hormones,” he says.

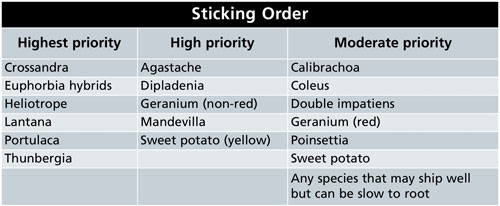

Table: If you get boxes with a lot of mixed species, this chart shows the best order for sticking cuttings.

Table: If you get boxes with a lot of mixed species, this chart shows the best order for sticking cuttings.

They used plain water as a control for comparison. Here are the results:

• Postharvest cutting dips in recovery solutions clearly improved rooting with all three plants used in the study—geranium, New Guinea impatiens and poinsettia.

• The best recovery solution recipe for geraniums and poinsettias: 30-minute dip into 400 ppm K-IBA (water-soluble IBA) plus either fructose or Pageant fungicide.

• The best recovery solution recipe for New Guinea impatiens: zero to 30-minute dip into K-IBA solution (400 ppm).

• Not only do recovery solutions help rooting, but turgid cuttings are physically easier to stick.

• Unstressed cuttings also benefitted from being dipped in a water + adjuvant solution

All recovery solutions included CapSil, a spray adjuvant or wetting agent. Adding wetting agent lets water bridge the waxy cuticle on leaf surfaces.

“CapSil improved cutting turgor, which was particularly important with tiny cuttings, like the New Guinea impatiens,” John says. He can see these dips playing an important role with sticking other bedding plant crops.

“Because we saw positive results, even with unstored cuttings using the wetting agent solution, I suggest working dips into your propagation process no matter what,” he advises.

Overall a 0-minute dip produced slightly less rooting than a 30-minute dip. “We didn’t have time to do intermediate dips, but I’m guessing an intermediate dip would work as well as a 30-minute. A quick dip works, but if you have the time, the longer duration could be better.”

He suggests testing dips, trying different recipes to see what works best for you. To refine timeframes, pull the cuttings out every few minutes to check turgidity. A clue that cuttings are submerged too long? Water-soaked patches on leaves where tissue has died and cells have exploded.

(The full research report contains the recipes used in the research. To view the free report, visit endowment.org and go to “Final Research Reports” under the Research tab. Scroll down to Post Production—400 series, and look for report #460.) GT

Julie Martens Forney is a freelance writer with more than 25 years of experience writing about floriculture industry issues and gardening for consumers. To read her current bylines, check out ASCFG’s Cut Flower Quarterly, SAF’s Floral Management and HGTV.com.