1/1/2022

The Latest on Growing Media Research

Drs. Brian Jackson, Jeb Fields, James Altland & Jim Owen

Research programs, both public and private, around the country are working individually and collaboratively on many projects aimed to address current problems, as well as future opportunities in the soilless substrate industry. As is true with most all research, there are short-term fixes and long-term solutions that can be achieved through data-driven, science-based, industry-linked projects. Ultimately, our stakeholders and those whom we serve are growers, home gardeners and the broader scientific community.

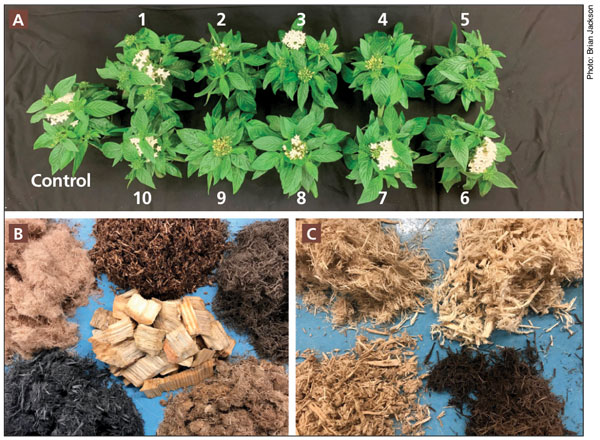

Figure 1. Pentas (A) grown in sphagnum peat moss amended with 40% (by volume) of 10 different commercial wood fiber products from Europe and North America (B-C). Photo: Brian Jackson.

All things wood

At North Carolina State University, a large focus of past and current research efforts has been on the engineering, characterization and utilization of wood-based substrate components. Wood remains one of the least understood, yet most promising, materials that continue to be viewed as one of the primary sources of substrate materials of the future to meet growing demand for soilless products. Recent trials in the Horticultural Substrates Lab have been evaluating commercially available wood products from both North America and Europe.

In 2021, researchers conducted lab and greenhouse trials on 10 wood products to compare fertility requirements, pH adjustments and modifications, PGR efficacy and hydration efficiency (comparing overhead and sub-irrigation). As one example of our observations from these trials, Figure 1A shows plant growth (with pentas) after six weeks when grown in Canadian sphagnum peat moss with a 40% wood inclusion rate of each of the 10 products tested. Plants in this photo were fertigated with 200 ppm N and irrigated similarly (other trials irrigated substrates independently based on water loss).

While there were some growth differences observed, the overall performance and quality of plants was positive. This, as well as other trial data, provide further evidence that while there are differences among wood products (Figures 1B-C) based on how they were processed, as long as they’re nontoxic, cultural modifications (water, fertility, etc.) can be adjusted to produce high-quality plants. Of course, as the wood inclusion rate increases, more challenges occur and more modifications have to be made compared to peat-based mixes without wood additions. More grower-focused information is forthcoming on wood substrate trials from NC State, as well as other research institutions.

Defying gravity

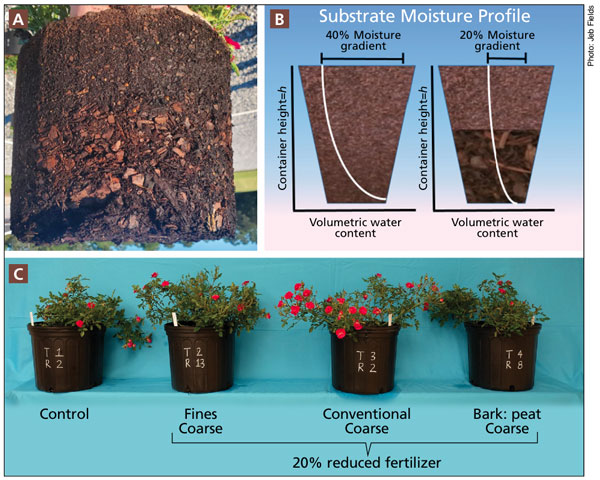

Stratified substrates, or layering unique growing media within a container, is a recent innovation in substrate management being led by Dr. Jeb Fields with the LSU AgCenter and Dr. Jim Owen with USDA-ARS. Stratifying substrates within the container was initially designed to improve resource management within container crop production. Primarily, improving water management and root growth through altering the physical nature of the container.

Layering substrates with high water-holding capacity on top of coarse materials to promote drainage allows re-engineering of the water distribution within the substrate system. Thus, defying gravity by promoting increased water holding in the upper portion of the container and reducing water holding in the lower—a reversal of a typical container system. This creates a more uniform moisture profile throughout the substrate and allows for improved water resource management, in addition to supporting improved root growth (Figures 2A-B).

Layering substrates with high water-holding capacity on top of coarse materials to promote drainage allows re-engineering of the water distribution within the substrate system. Thus, defying gravity by promoting increased water holding in the upper portion of the container and reducing water holding in the lower—a reversal of a typical container system. This creates a more uniform moisture profile throughout the substrate and allows for improved water resource management, in addition to supporting improved root growth (Figures 2A-B).

Figure 2. Novel stratified (layered) bark substrates are improving water and nutrient efficiencies in container crops. Photo: Jeb Fields.

Moreover, increasing fertilizer efficiency within the container through incorporating fertilizer in the top strata reduces fertilizer leaching and remains available to plants (Figure 2C). This concept is still in the primary phase of research, but early observations show that stratified substrates can produce similar crops with less water and fertilizer.

Stratified substrates also have the potential to lower media costs by stacking high-cost substrates on top of low-cost substrates (i.e., utilizing a low-cost pine bark substrate on the lower portion in high-performance, peat-based media) may cut media costs with additional potential benefits.

More coir, please

Researchers at NC State and the University of Arkansas (Dr. Ryan Dickson) are teaming up to conduct a robust evaluation of coconut products (fiber, chips, coir, etc.) with the goal of supporting the global manufacturers, suppliers and distributors of these critical substrate materials that are, and will remain, in extremely high demand.

Figure 3. Coconut substrate products are being evaluated for physical and chemical consistencies, and advanced preconditioning methods for product enhancement. Photos: Brian Jackson & Dutch Plantin.

Figure 3. Coconut substrate products are being evaluated for physical and chemical consistencies, and advanced preconditioning methods for product enhancement. Photos: Brian Jackson & Dutch Plantin.

Coconut substrates are utilized extensively in the production of container-grown soft fruits, cannabis and foliage plants, as well as other greenhouse mixes and retail consumer products. Working with the industry to further improve or advance processing and preconditioning methods, and helping to develop novel mixes and product formulations, could help to further bolster the global use and reliance of these substrates in current applications and in future markets. Specific efforts to work with the coconut industries in Mexico, as well as those in the South Pacific, to understand the needs and opportunities will be critical to our comprehensive endeavors.

Soilless, not soulless

Research at the USDA-ARS Application Technology Research Unit and The Ohio State University (OSU) is unraveling the biological properties of soilless substrates. Silvia Valles, a Ph.D. student at OSU, is leading this effort by using Next-Gen (NG) amplicon sequencing techniques on soilless substrate DNA to determine the impact of substrate management practices on the microbial community.

For decades, scientists have studied the bacteria and fungi in soilless substrates by observing the growth or suppression of one organism (beneficial or pathogenic) at a time. Using the NG amplicon sequencing approach, Silvia is identifying the entire microbial community (bacteria and fungi) living within the substrate.

The first goal of her research was to document the breadth of the community and how it changes over time under different management strategies. In this work, substrate components such as pine bark, peat and compost affected the makeup and diversity of the microbial community early in the experiment. However, over time, the communities tended to become more similar regardless of substrate components, as the environment (temperature, irrigation water, etc.) had more influence on the community than the original substrate.

Figure 4. Silvia Valles, a Ph.D. student at The Ohio State University, is studying the microbial community of soilless substrates using Next Gen amplicon sequencing techniques. Photo: James Altland.

Figure 4. Silvia Valles, a Ph.D. student at The Ohio State University, is studying the microbial community of soilless substrates using Next Gen amplicon sequencing techniques. Photo: James Altland.

Silvia is also developing streamlined procedures to rapidly collect, isolate, purify, amplify and analyze samples and provide a succinct report for growers and substrate professionals. This and other work at USDA-ARS and OSU is beginning to shed light on the increasingly important biological properties of container substrates.

The need for stability

The authors of this article are also working together to understand the current and future substrate needs of the ornamental and specialty crop producers in North America. As more consumable perennial crops, (i.e., cane berries and citrus) are shifting production to soilless cultivation systems, the need for longer-term substrate stability has to be addressed. For fruit crops, for example, that will spend five to eight-plus years in containers, the substrates used in those systems have to be resilient enough to provide the physical, chemical and biological stability/properties needed by the crops to optimize yield and productivity throughout their production life.

Innovative strategies by our research team (and others, notably Dr. Gerardo Nunez at the University of Florida) are being conceived, strategized and employed to develop soilless substrate solutions for the future. GT

Brian Jackson is a Professor of Substrate Science and Director of the Horticultural Substrates Laboratory at North Carolina State University. Brian can be reached at Brian_Jackson@ncsu.edu. Jeb Fields in an Assistant Professor at Louisiana State University. James Altland is a Research Leader and Horticulturist, and Jim Owen is a Research Horticulturist, both at USDA-ARS in Wooster, Ohio.