11/1/2021

Growers Talk About Their Cutting Robots

Chris Beytes

Aaron Van Wingerden, Dutch Heritage Gardens (two ISOs)

How many years have you run your machines and how many cuttings do you stick per year?

“Three years, 5 million-plus cuttings per year, with two machines. We set up the line for an additional two, which we will install next year.”

Pictured: AutoStix’s multiple grippers (three or six depending on model) grip and plant individual biodegradable “clips” that come in 34- or 51-count “strips.”

What do you like best about it?

“It never takes off due to COVID concerns! (insert smiley face). On a serious note, one machine plants 1,800 to 2,000 cuttings an hour, perfectly, while one really good employee can stick 400 to 500 cuttings an hour.”

What do you wish it could do or could do better?

“Plant larger cuttings better. If the cutting is top-heavy, then the gripper fingers have a hard time keeping the cutting straight up and down during stick.”

Has it paid for itself? How and how quickly?

“Yes! In labor-saving. Took two years.”

Any advice to other growers considering a URC-sticking machine?

“Any greenhouse that sticks 500,000 cuttings or more a year will have one machine pay for itself in five years or less. It’s almost foolish NOT to get one or the other, especially with the labor shortages we have going on now.”

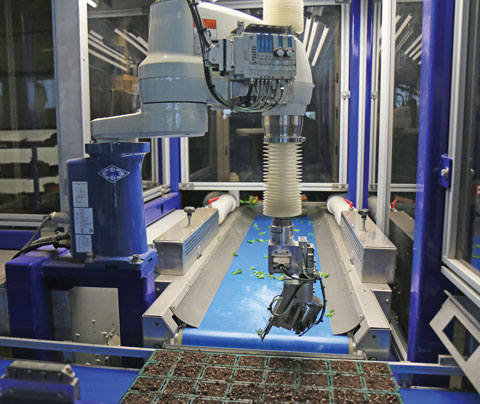

Pictured below: ISO’s gripper, guided by cameras and a computer, picks up and sticks individual loose cuttings from a belt.

Glenn Anderson, Nordic Nurseries, Abbotsford, British Columbia (one ISO)

How many years have you run your machine and how many cuttings do you stick per year?

“We are going into our third season with our ISO Cutting and TransPlanter [Editor’s note: this model can stick URCs and transplant rooted liners], and it has helped us a lot. In the three months we stick cuttings, it sticks three million cuttings. We start running it in December and run two shifts, six days a week, sticking cuttings until mid-March. We then change it over to transplanting for five to six weeks. The changeover takes only five minutes.”

What do you like best about it?

“What we really like about the ISO is that it sticks cuttings very consistently. It sticks 2,500 cuttings per hour and transplants at the same speed. Also, the model we have, the ISO Cutting and TransPlanter, allows us to use it longer and we love this versatility.”

What do you wish it could do or could do better?

“We have found that it’s important to use varieties that work best on ISO in order to achieve the highest production. We stick primarily calibrachoa, nemesia, osteospermum, verbena and bacopa, as they run the best. The operator does have to patch the trays a bit, but if cuttings are good quality this is minimal.

“We have found that the key to running ISO efficiently is to have a good partner in our URC supplier who understands ISO’s needs and an operator who is attentive.”

Has it paid for itself? How and how quickly?

“Our ISO has not paid for itself yet, but it has greatly helped us in managing our peak weeks sticking cuttings and has reduced our labor needs. Finding good seasonal labor has become increasingly challenging, as we all know. ISO is not cheap, but automation is here to stay.

We love our ISO machine and hopefully will add another one soon.”

Any advice to other growers considering getting a URC-sticking machine?

“Work with your URC supplier to ensure that cuttings have enough of a stem for ISO to see it clearly. Use ISO for the varieties that run best on it and let people stick the more difficult ones.

“To be efficient, you want to run bigger batches on ISO. Switching over between every tray or two causes too much down time.

“ISO doesn’t need coffee breaks, so have someone run through breaks so the machine keeps running. Run as many hours a day as possible to make it pay for itself faster.”

Chris Hansen, Hampshire Farms, Hampshire, Illinois (one AutoStix)

How many years have you run your machine and how many cuttings do you stick per year?

“We got our AutoStix in August of 2017, so four seasons. We plant roughly 3 million cuttings.”

What do you like best about it?

“The ability to run volume through it. Historically, we’d get in large lots of cuttings—10,000 or 20,000 of this or that. When that happened, everything would stop. We’d pull the planting crew and the production crew and the shipping crew and everybody would go back and stick cuttings for a couple days and everything else stops. With the AutoStix, we have one or two people operating it to do the same amount of cuttings in a couple of hours that 15 or 20 people could do in a couple days.”

What do you wish it could do or could do better?

“I can’t really say anything because I don’t think we tapped its full potential at this point. I know we have the ability to hook it up to monitoring systems to record a lot more data than we are. At this point, we’re using it as a sticking machine rather than a sticking and data-accumulation machine.”

Has it paid for itself? How and how quickly?

“Short answer? Many times over. As far as the absolute dollars, we paid it down within two years. You have the choice between a human sticking a cutting—which, depending on how good they are, can do 600 to 800 an hour. The AutoStix can do up to 10,000 an hour if it’s rocking. But the choice has not been paying a human to do it or paying a machine to do it. The choice has been having a machine do it or buying in rooted cuttings from another supplier. We just can’t find people [to stick cuttings]. We just don’t have the people to do it even if we wanted to do it.”

Any advice to other growers considering getting a URC-sticking machine?

“Automate as fast as you possibly can. If you can put a motor on it or a belt under it, do it as soon as you can.”

Art VanWingerden, Metrolina Greenhouses, Huntersville, North Carolina (five ISOs)

How many years have you run your machines and how many cuttings do you stick per year?

“We’ve had them five seasons now. We’re running them 38 to 40 weeks out of the year now. And we’re averaging about 2,200 cuttings per machine per hour. During the busy times—I’d say 12 weeks out of the year—we’re running 24 hours a day.

What do you like best about it?

“Speed. Speed and consistency. The cutting is always in the middle and the cutting is always the same depth.”

What do you wish it could do or could do better?

“The only thing I wish it could do is go faster … and they’re working on that … they’ve got new models that are going faster now. And there are some items that we’re getting close to 3,000 per hour. They’re definitely making them better and better.”

Has it paid for itself? How and how quickly?

“I’d say they paid for themselves in three years, that’s my guess. And that’s when labor was available. I think they’d pay themselves off a lot quicker now because labor is so tight.”

Any advice to other growers considering a URC-sticking machine?

“To me, if you are what I’d consider a medium-sized grower, say 6 or 7 acres up to about 20 acres, in my opinion you ought to take a hard look at AutoStix. I think that’s the way to go because you have so much change-over time. Unless you’re a one-crop facility—which we have very few of in America.

“Once you get over 30 acres, the ISO makes sense. I had both of them, ran them side by side for a year, and that’s what I saw. When you have a lot of changeovers, the AutoStix is better, but you’re going to spend a little more money on the cuttings.

“The way I look at it, it basically costs a penny in labor (per cutting) to run an ISO, two cents in labor to run an AutoStix and three cents to stick it by hand. That’s Art’s easy math.”

Bob Dickman, Dickman Farms, Auburn, New York (three AutoStix)

Which machines do you have and how many have you got?

“We own three AutoStix machines and will take delivery on number four in early January.”

How many years have you run your machines and how many cuttings do you stick per year?

“Five years, 13 million cuttings per year.”

What do you like best about it?

“Versatility, accuracy and speed of sticking cuttings in peak.”

What do you wish it could do or could do better?

“The first three machines are generation 1 AutoStix and we have had problems with wear parts in season that take time to fix. The machine we purchased that will arrive in January is a newly developed AutoStix that we believe it will be much more reliable in peak season and not have wear part issues.”

Has it paid for itself? How and how quickly?

“It has paid for itself by allowing us to stick a high volume of cuttings in peak season without having to bring many more seasonal workers. We also see better uniformity and crop performance.”

Any advice to other growers considering getting a URC-sticking machine?

“When we look at automating production, we consider three factors: volume of product (batch size and versatility of the machine); ROI (benefit of true monetary return on investment based on overhead and looking at being able to get work done more efficiently); and will it improve overall quality to the product we are producing.”

James Darrow, Jolly Farmer, New Brunswick, Canada (two ISOs)

Which machines do you have and how many have you got?

“We have two ISO Cuttings Planters and expect to add two more next year.”

How many years have you run your machines and how many cuttings do you stick per year?

“First machine 2018, second machine 2019. Approximately 2 million cuttings per year. This number grows every year.”

What do you like best about it?

“Considerable labor saving. During the busy season we run them around the clock, reducing peak labor needs considerably.”

What do you wish it could do or could do better?

“We wish we could do more varieties on the machines. (But) suppliers are getting better at producing ISO-friendly cuttings, resulting in more varieties each year.”

Has it paid for itself? How and how quickly?

“YES! As we all know, hitting peak labor needs is a big challenge. These machines have been instrumental in shaving this peak to a manageable size.”

Any advice to other growers considering getting a URC-sticking machine?

“Look hard at what will work for you. We ran an AutoStix and an ISO machine side by side in 2018 and found the ISO fit our needs better without the ‘per-stuck’ cost for the AutoStix cuttings.

“If you purchase an ISO machine, work with your (URC) supplier on stem length to accommodate the machine better.”

Jeff Back, Four Star Greenhouses, Carleton, Michigan (four ISOs, one AutoStix)

Which machines do you have and how many have you got?

“We have the ISO 2500 machine, four of those; and we have one AutoStix.”

How many years have you run your machines and how many cuttings do you stick per year?

“The ISOs we’ve had since 2017. We bought two the first year, then we added a third in 2019 and a fourth in 2020. The AutoStix we’ve had since 2018. Last year we ran 8 million cuttings on each—almost a dead heat.”

What do you like best about it?

“The ISOs we like because they’re very versatile. We can do several different items [at the same time] because we have multiple machines. And we can do a lot of different varieties. We can do small batches on them … versatility is the key to them.

“The AutoStix is speed, straight-out. It is a speed machine. The output is about the same running four ISOs as running one AutoStix. AutoStix is really easy to use—it’s about the same as running a transplanter.

“When we get down to the smaller batches, we definitely go towards the ISOs. We run the ISOs all year, we run the AutoStix from about Week 48 to Week 14.”

What do you wish it could do or could do better?

“If anything, I guess it would be nice if you could [stick] more with one machine. You end up taking up a lot of room buying four, five, six machines … it takes a lot of machines to get things done.” (Jeff says they’re sticking 2,200 to 2,600 cuttings per hour per machine.)

“The AutoStix is a little bit cost-prohibitive. There’s definitely more expense in using the AutoStix just because of what we’re paying for the clips. You’re always going to have the cost of the clip and that ends up being a per-cutting cost—you’re talking a couple of cents per cutting and that can be pretty expensive.”

Has it paid for itself? How and how quickly?

“Yes. [But the challenge] when we talk about the AutoStix is the input. How do we make the input pay because there’s always the cost of the input, the clip.

“The ISOs can pay for themselves in four years, especially when you run them as much as we do. I’d say you need to be running at least 2 million (URCs) a year on the ISOs to get a four-year payoff.

“On the AutoStix, I’d say just in pure labor-savings, it paid for itself within three years. I mean, it’s infrastructure, right? The amount of people it takes to stick 8 million cuttings that I’m doing on that AutoStix … I don’t have breakroom space, I don’t have restrooms … there are unseen costs that you have to calculate.”

Any advice to other growers considering getting a URC-sticking machine?

“Really have a good handle on what your labor costs are. And run them hard—really get the hours out of them. For us, running them 20 hours a day is where we really gained the most.”

Times change—you can, too

Don’t feel that investing in a URC planter locks you into the annual and perennial business forever. Take Jim Gibson of Timbuk Farms, who sold his three ISOs last year to a major East Coast grower.

Explained Jim, “Our business changed with the trend of foliage and succulents, and we had to choose a focus. Young plants are very labor intensive and we all know the struggles with labor. In the end, we decided to shrink our young plant business to only begonias and the machines were not used as much.”

He added, “We have no issue with the machines and felt we did get a good ROI.” GT

Machines

Cutting-sticking technology continues to evolve, thanks to the two machine manufacturers, ISO Group and Visser, who listen to customer feedback and upgrade their machines with the latest hardware and software improvements. Here’s what’s on their drawing boards:

ISO has launched a new robotic solution for growers: the ISO Sorter and Planting Machine. Like the original ISO Cutting Planter 2500, it sticks URCs into your choice of media consistently and dependably. But it adds a grading element, using a camera system to check the size of each cutting, then planting it with other similar cuttings. It can grade into four sizes—small, small-medium, medium-large and large—giving you more uniform trays of cuttings in the greenhouse. It’s well-suited to propagation specialists doing large quantities of the same crop.

Visser is working on a new generation of AutoStix that will feature several updates, most notable of which is a new path of motion for the gantry, which will be more linear and less stiff, making for more efficient planting with less stress on the machine components. They’re also upgrading the strip bed (where workers place the AutoStix strips) to be less complex and easier to set up. And as Bob Dickman mentions, they’re improving the durability of many components. Software-wise, they’ve added Spanish to the control menu. The revised machine will be tested this coming spring at a major U.S. grower before launching commercially. —C.B.