9/1/2021

Cultivate’21: Live and In-Person Once Again!

Chris Beytes, Jennifer Zurko, Bill Calkins & Jennifer Polanz

Did you attend Cultivate’21 in Columbus, Ohio, in July? If so, we’re sure you noted the same three things we did:

1. Everyone was in a good mood—we were out in public! Without masks!

2. Everyone had money to spend and was doing some serious tire-kicking.

3. Everyone was told, “Sure, we’ll gladly fill that order … hopefully by Christmas!”

The mood was good because of #2 above, since most of the industry had a fantastic spring. Overall, it felt as much like a “normal” Cultivate as one could hope for.

Attendance-wise, we heard good things. GrowerTalks Managing Editor Jen Zurko attended a meet-and-greet with AmericanHort CEO Ken Fisher, and while it was too early for concrete numbers at the time, Ken reported that pre-registration numbers were very good, at about 7,400, and walk-in traffic seemed to be excellent. There were many fewer international visitors and about 100 fewer booths (most of those being Canadian or European companies), but overall attendance wasn’t down by much. (We’ve since asked AmericanHort for final attendance numbers, but they haven’t shared exact totals.)

Most importantly, the right people were in attendance: customers. Throughout the three days of the trade show, we asked various exhibitors about how their show was going, and 100% of them were content with the quality of the audience and the business that was taking place.

The Ball Publishing editors spent all three days working the show to sniff out the best and most interesting new products from a wide range of categories. Here are the highlights:

Applicators

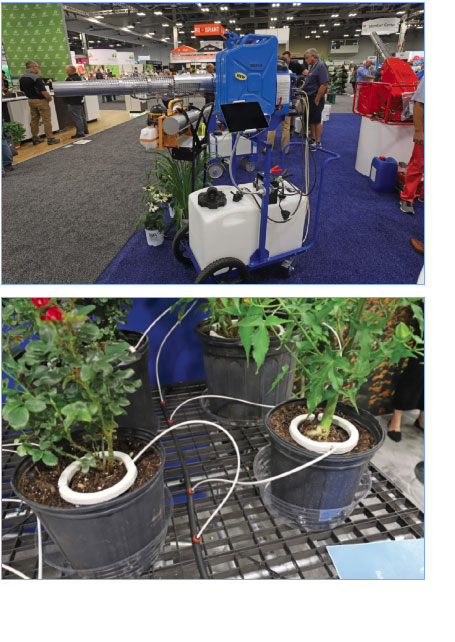

Dramm’s Dual-Start PulseFog

Dramm’s new K-30/20 BIO DS Dual Start PulsFOG is the smallest unit they now offer with a Dual Start option. The Dual Start offers two starting mechanisms: a push-button, compressor-driven system for easy starting when connected to a 12-volt battery, and the manual priming ball for when no larger battery is available. The K-30/20 BIO DS can treat areas up to 210,000 sq. ft. with the included 55-liter tanks. The BIO feature uses a secondary tank for plain water and a separate set of injection nozzles. This system cools the exhaust produced by combustion before the chemical solution is injected, preventing damage to heat-sensitive products.

Irrigation

Netafim’s NetBow

Netafim’s NetBow is a container irrigation ring that replaces spray stakes. The benefits include more uniform distribution of the water, less water use and no water spraying on the lower portion of the plant. NetBows come in two sizes: 10 in. and 5 in. The 10 in. has eight Typhoon emitters that put out ½ gal. of water per hour; the 5 in. has four emitters.

Automation

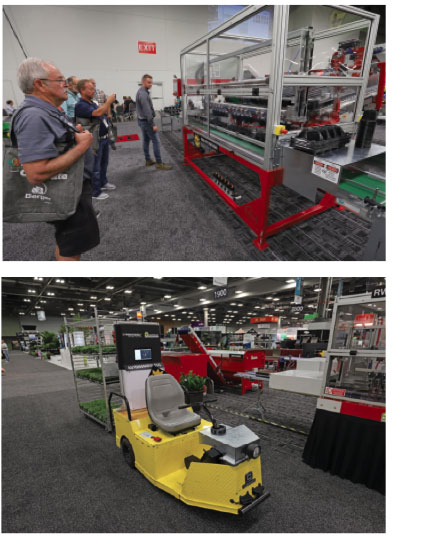

The Autonomous Tug from AgriNomix

If you don’t know, a tug is a battery-powered vehicle used for towing shipping carts (or trailers) around the greenhouse. It requires a human operator to drive it, meaning a staffer is tied up doing unfulfilling, low-value work.

In Europe, there are autonomous tow vehicles, but they always require a wire in the floor for guidance, meaning they’re stuck following a set path. AgriNomix’s machine, developed in partnership with Cyberworks Robotics of Ontario, isn’t guided by four cameras and 2D “April” barcode tags. You set its route simply by driving the route (which has to be a loop, as it can’t currently back up), then turning the machine loose to repeat the loop all day long. It can be set to stop along the way, like a bus route, for workers to detach, attach, load or unload carts. Sensors prevent it from running over your staff. If you have multiple tugs all running autonomous routes, there's “air traffic control” software to control multiple paths.

In Europe, there are autonomous tow vehicles, but they always require a wire in the floor for guidance, meaning they’re stuck following a set path. AgriNomix’s machine, developed in partnership with Cyberworks Robotics of Ontario, isn’t guided by four cameras and 2D “April” barcode tags. You set its route simply by driving the route (which has to be a loop, as it can’t currently back up), then turning the machine loose to repeat the loop all day long. It can be set to stop along the way, like a bus route, for workers to detach, attach, load or unload carts. Sensors prevent it from running over your staff. If you have multiple tugs all running autonomous routes, there's “air traffic control” software to control multiple paths.

For outdoor nursery use, the system can be fitted to a tractor for hauling wagons. It’s controlled by GPS and orange cones can be placed where you want the tractor to stop.

Best of all, if you already have tow vehicles, the system can be fitted to them—you don’t have to scrap your fleet and buy something special. Cost is about $15,000 to $18,000 per vehicle, plus $10 per hour per vehicle for the cloud software that controls them.

Most interesting is that this cool technology didn’t come from the Netherlands—it came from right here in North America.

Also new from AgriNomix: three new pot dispensers that are arranged with the pots laid almost horizontally next the conveyor belt rather than suspended vertically over the belt. Why this setup? It’s easier for employees to load; the trays don’t have to be turned on the belt; and the dispensing head only moves 120 degrees, not 180 degrees, for more speed and efficiency. The PDX1 has one pot transport head, the PDX3 has three (to fill three trays). Heads can be changed for various pot sizes. About the only drawback is its footprint. There’s also a CDX1 for nursery cans.

Containers and tags

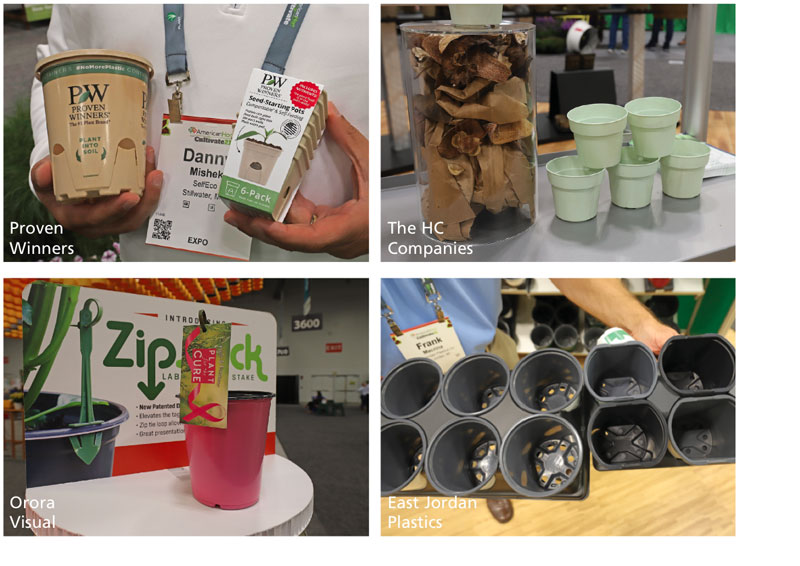

Sustainability is making a comeback (not that it ever went anywhere). Here are three bio pot solutions:

Proven Winners is launching their first compostable pot, the Eco+Grande. It’s plantable—you tear away tabs from the bottom to expose the roots to the soil. The pot is made from plant-based material (PLA, or polylactic acid, made from starchy plants) and it includes plant-based nutrients in the pot to help feed the plant. Watch for it in ’22 (we believe it's going to be white when it's introduced).

Proven Winners is launching their first compostable pot, the Eco+Grande. It’s plantable—you tear away tabs from the bottom to expose the roots to the soil. The pot is made from plant-based material (PLA, or polylactic acid, made from starchy plants) and it includes plant-based nutrients in the pot to help feed the plant. Watch for it in ’22 (we believe it's going to be white when it's introduced).

The HC Companies has a new line of bio pots called BioPax, made from more than 50% biodegradable and compostable materials, mainly wood pulp and wood pulp resin. They're compostable, taking three to five years to break down in the landfill, meaning they should hold up well in the greenhouse. In fact, other than the swirly, marbled color, you can’t tell they aren’t traditional plastic. Said HC, this product is a good first step into using bio pots and you don’t have to change your production systems or methods.

Orora Visual showed their first-ever line of 100% post-consumer recycled plastic packaging, which includes pots (from Nursery Supplies), stakes and tags. The stakes are especially interesting: called Zipsticks, they have a zip tie built into the top of the stake, with which you can affix the plant tag or tags. The base of the stake features a pot lock. And their recycled tags come in both locking and hanging styles.

East Jordan Plastics offers a new “Stadium Pot” designed to give you the same soil volume, but in a narrower tray, giving you free space in the greenhouse and shipping rack. The 1-pint, 1.5-pint and 2-pint sizes are 20 to 50% smaller than standard round pots. The flat sides make for easy labeling, while the curved sides can accommodate your brand messaging.

Chemistries

Avelyo and Finale XL from BASF

BASF introduced two new products at Cultivate. The first is called Avelyo, a fungicide that they say includes a first-of-its kind chemistry called Revysol, which is the active ingredient mefentrilfluconazole that helps to provide preventative control of foliar, crown and root diseases. You can use it as a spray or drench to control Anthracnose, black spot, leaf spot, powdery mildew, rusts (suppression only) and stem blight. Avelyo is labeled for uses in commercial and retail greenhouses and nurseries, for cut flowers and houseplants, plus juvenile fruit and nut trees.

The second is an herbicide called Finale XL T&O. With many companies phasing out glyphosate, BASF says that Finale XL is a good alternative that for weed control. Their trials have shown that it doesn’t cause plant damage, so it can be used in the greenhouse when plants are present. When applied, weed growth is stopped within hours to days. It’s also a great tank mix partner with preemergence herbicides.

Fine Americas’ Advocate and Crest

Here are two rooting and growth enhancement products from Fine Americas. Advocate is a new formulation of IBA rooting hormone. It’s a very potent 20% liquid concentrate (“A little bit goes a long way!” they say) so it’s economical. It's also unique in that you can use it as a dip or you can spray it on the plant after sticking—a bit of a labor-saver. Fine says it can also be applied during growth as a root stimulant.

Product #2 is Crest, a “three-way biostimulant.” Crest contains IBA, for rooting; cytokinin, for branching; and gibberellic acid (A3), for vigor. The combination is said to boost seed germination, shorten germination and emergence time, and boost the vigor of young plants.

Fine says you can use the two products in tandem (but not as a tank mix; just in rotation) to boost rooting and encourage vigor in all crops.

Nutrition

Dosatron’s no-metal D40

Dosatron’s no-metal D40

The latest injector from Dosatron is an upgrade of their D40 that now features all-plastic construction—they removed ALL the metal components (screws and springs) from the interior mechanism so you no longer have to worry about corrosion or breakage (apparently, the springs could snap if you exceeded the maximum flow rate).

It also features a replaceable flange, so you don’t have to worry about the body getting nicked and damaged after repeated maintenance. Other than that, you can’t tell the new D40 from the old D40! The D40 handles 2.2 to 40 gallons per minute.

MycoApply EndoThrive from Mycorrhizal Applications

MycoApply EndoThrive is a new concentrated liquid formulation that contains multiple types of endomycorrhizae in a non-aqueous liquid carrier. That means it can be pushed through drip tape, emitters and even mixed into fertilizer stock tanks. According to Sales Manager Blair Busenbark, the carrier protects the mycorrhizae so they're not damaged during the distribution process. He adds that if it’s being used in hydroponic growing, the mycorrhizae need sufficient oxygen.

Just as a refresher, mycorrhizae colonize the root system of many plants, branching out to bring more nutrients and water to the plant. This product comes in a 1-pint container that equals 200 gallons of drench in a greenhouse or application on 80 acres of turf.

PurKote controlled-release fertilizer from Pursell

It was only Pursell’s second year exhibiting at Cultivate, but they’ve been in the fertilizer biz for years. You know the Sta-Green controlled-release lawn fertilizer you’ve seen everywhere? Sales & Marketing Director Jason Woulfin said that the Pursell family invented it years ago. Sta-Green Fertilizer was originally called Sylacauga Fertilizer Company, then Parker Fertilizer Company, after its founder, DeWitt Alexander Parker started the company in 1904.

The Parker Fertilizer Company was handed down to DeWitt’s son, Howard Arrington Parker then his son-in-law, Jimmy Pursell, became his partner. The company is now known as Pursell Industries and is in the hands of DeWitt’s great-grandson Taylor and they’re still based in Sylacauga, Alabama.

Although the company’s history is based on turf and lawncare, they have controlled-release fertilizer formulations for row crops, ornamentals and what they call “specialty ag,” which is for fruit and nut trees, etc. The ornamentals formulation is called PurKote, which is noticeable because of its purple coating. “We wanted it to stand out,” said Jason.

Pursell has five formulations for the horticulture market under the PurKote brand, with custom formulations available, too, and each one offers a way for growers to create a targeted program. Find out more at pursellfertilizer.com.

Growing media

HydraFiber’s product expansion

HydraFiber’s product expansion

During the last few years, HydraFiber’s wood substrate products have been gaining unbelievable traction in our industry. They just installed their 100th machine and many large growers have added HydraFiber formulations to their growing media.

But not all growers have the resources to have their own HydraFiber machine, so Jennifer Neujahr, Director of Business Development, said that they continue to look for new ways to get their product to these operations.

One new product that’s ideal for growers that don’t have a lot of automation is the EZ Blend that includes more bark, so it breaks apart much easier in most peat or bale-busting machines (and it looks similar to peat, so that helps). And EZ Blend is available as 40-lb. bales through multiple companies, including Griffin, Berger, BFG and Midwest Trading.

We’ve mentioned HydraFiber’s partnership with FibreDust in these pages before when we first saw it at the MANTS show in January 2020, but this was the first full roll-out of the compressed blocks that contain the HydraFiber wood substrate along with FibreDust’s coir. Jennifer said they work just like coir blocks and are engineered to be used on their own or blended. You can also add whatever amendments you’d like.

When you take washed coir and add HydraFiber, you can have better control of your salt levels, she said. And it provides a great option for cannabis growers, who usually can’t grow in buffered coir because it’s not organic.

One block expands to six times its original size and one pallet covers 520 cu. ft. (In comparison, a typical coir block expands to five times its size.)

Some session recaps

By Bill Calkins

Is Your Water as Good as It Could Be?

Presented by Al Zylstra, Dramm Corporation

One of the Saturday sessions I sat in on was a discussion about water quality presented by Al Zylstra, one of the technical guys at Dramm. He’s an industry vet with a lot of experience in many greenhouse systems, and was quick to share tips and tricks, as well as plenty on what NOT to do.

Here are his five high level tips for those of you looking to improve water quality in your greenhouse:

1. Know the chemistry of your water. Al talks to tons of growers and says too few of you really do the analyses required to truly know what you’re working with. Analyze the nutrients and ions. Know your Biological Oxygen Demand and Chemical Oxygen Demand. Consider a DNA scan of your water, and at the very least, send in a water sample so you understand your major and minor nutrients and metals.

2. It sounds intense, but Al recommends constant monitoring of your water and irrigation process. This includes all levels. EC, pH, Pressure and Flow Rate should be monitored hourly, while Dissolved Oxygen and Oxidation Reduction Potential should be on your daily list of levels to watch, according to Al.

3. Use the right tools. Al spent a lot of time talking about Reverse Osmosis (R.O.) He says sometimes it’s the best tool for the job, but it’s all-too-often overused or not used correctly. He reminded attendees that the R.O. process “throws away” 25%+ of your water. It’s expensive to operate, adds to your necessary maintenance and doesn’t ensure disinfection. It does, however, remove salts, polishes water and benefits crops that need VERY precise chemistry.

4. Prioritizing irrigation efficiency is key. Don’t waste your water or nutrients. According to Al, this comes down to knowing the plant demand and watering to meet the needs. He says water won’t be cheap for much longer and keeping data on the amount of water going to each zone is important. Efficiency comes down to professional system design, precision emitters and automated controls.

5. You can safely recycle leachate water. Al was quick to point this out, saying modern systems can be effective and the tools are available to filter, disinfect and mix leachate water back in. There’s cost savings to be gained and the payback for systems can be as short as two to three years in fertilizer use alone.

The Template Method for Growing: Case Studies in Maximizing Quality and Efficiency

Presented by Matt Foertmeyer, Bob Dickman & Jason Twaddell

On Sunday, three growers presented an eye-opening discussion about production planning that takes strategy to the next level. Matt Foertmeyer, Bob Dickman and Jason Twaddell shared an exploration of how they build production templates that allow for strategic direction, data collection and improvement immediately, and for subsequent years.

Developing a defined production template for every crop sets expectations and results in a guide for the entire team to follow. According to the presenters, it’s proactive vs. reactive, allows you to hit tight sales windows and even tighter retail specs, reduces guesswork, and improves training and helps your group plan tasks by creating roadmaps. Having a clear template for all phases of every crop, saved digitally, includes creating visual and measured specs at each stage of production (propagation, vegetative growth, flower and finish). The speakers add data on ship week, height, width, number of blooms, percentage of color and more. Consider what’s most important for your crop and include those things in your template.

Lastly, here were the dos and don’ts they shared:

DO:

• Photodocument

• Keep notes

• Stay focused on what’s critical

• Look at new genetics as improvements

DON'T:

• Guess

• Be too rigid

• Forget to review

• Forget to communicate with team

Where Did That Come From? Disease Control in Propagation

Presented by Dr. A.R. Chase, Chase Horticultural Research

We all love Ann’s no-nonsense style and it was clear this topic is one that’s near and dear to her as a greenhouse problem solver. She went through common sources of disease in propagation, the most likely pathogens that result and then offered steps to take to reduce risk.

Here’s a quick overview and a good reminder about the importance of vigilance and not cutting corners when it comes to cleanliness:

• Liners and plugs (all pathogens)

• Unrooted cuttings (all pathogens)

• Seeds (bacteria, Alternaria)

• Water (Pythium, Phytophthora)

• Airborne (Botrytis, downy mildew, powdery mildew)

• Benches (Fusarium, TMV, Rhizoctonia, Phytophthora, Pythium)

• Containers & Media (Rhizoctonia, Pythium, Fusarium, Phytophthora) GT