1/1/2021

A Case Study in Lean

Jennifer Zurko

It’s not uncommon for those new to Lean Flow to be skeptical. Major change can be an inconvenience even for the most adaptable of us. But many have said once they see the benefits and results from implementing Lean Flow practices in their operations, they’re sold.

It’s not uncommon for those new to Lean Flow to be skeptical. Major change can be an inconvenience even for the most adaptable of us. But many have said once they see the benefits and results from implementing Lean Flow practices in their operations, they’re sold.

Pictured: Before they went to progressive sticking, each tray was transplanted by one person. Photo courtesy of Gail Berner.

This was the case with Spring Meadow Nursery in Grand Haven, Michigan. Propagation Manager Gail Berner, who’s been with the company for 27 years, said they’ve always tracked their productivity and knew there was room for improvement. In 2009, FlowVision first came to Spring Meadow to train the managers on how to utilize their staff in the most efficient ways possible. And from there, they’ve been implementing Lean Flow in different areas of the operation. It’s been a 10-year “journey,” said Gail.

Progressive carrots

FlowVision’s progressive sticking process is inspired by the famous Henry Ford, who came up with the concept of building cars using an assembly line of workers. In the greenhouse, instead of one person sticking one tray, the tray is split into thirds and multiple people finish the tray together.

When progressive sticking was first explained to Gail, she wasn’t so sure. “It made no sense to me why more touches would equal higher productivity—I thought it was just counterintuitive.”

And it was challenging to get buy-in from their employees. The first year they tried progressive sticking it didn’t get off the ground.

“People don’t like change; they will come up with a million reasons why it’s not a good idea,” said Gail, so they dropped the trial and made some small, incremental changes instead.

The next year, after introducing some new employees to the mix and getting current staff used to the idea, they tried it again.

“We get some new people every year, and they’re a little more open-minded and not so set in their ways, and lo and behold, it did make a difference,” said Gail. “We got about 13% higher productivity by just doing that.”

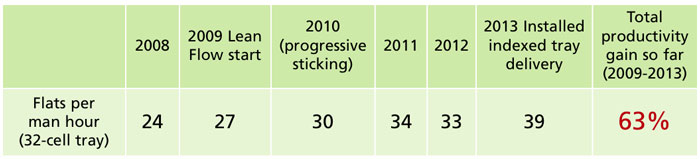

Gail said that Spring Meadow does a direct stick into 32-cell trays, and before they implemented Lean Flow, they were finishing 24 flats per person per hour. Once they changed over to the assembly line concept of progressive sticking in 2010, the production increased to 30 flats per hour per team. And it went up from there—in 2011, Gail said they were sticking 34 flats per hour. Within five years, combining Lean Flow and automation (like an index tray sticking machine), they saw a 63% increase in productivity (see Figure 1).

Figure 1. With progressive sticking and additional automation, Spring Meadow saw a 63% increase in productivity over a five-year period. Courtesy of Gail Berner.

Figure 1. With progressive sticking and additional automation, Spring Meadow saw a 63% increase in productivity over a five-year period. Courtesy of Gail Berner.

“Everything takes time to get used to and get it ingrained in your head, and I think that the progressive sticking was a two-year implementation to really get it,” Gail explained. “We have people come and go, so you always have inexperienced people and they’re the ones that pull down the rate. But in a progressive team, for example, you put that slower person in the middle and you have an experienced person on the left and right, so they’re getting pushed and pulled at the same time, and they get into a rhythm easier than if they were just by themselves at their own table.”

For over 20 years, Spring Meadow has offered productivity incentives for employees if they stick and transplant beyond a set goal, and Gail has noticed that the team dynamic provides them a way to help each other out.

“It makes us money when people are incentivized to produce more, quality product,” she said. “So that was the carrot that gets people to open their mind a little bit—because they may make more money.”

Eliminating the bottlenecks

Spring Meadow has also used Lean Flow to improve its order-fulfillment process. Shipping Manager John Papes said it’s helped eliminate unnecessary steps and alleviated the bottlenecks they were experiencing on the shipping dock.

Before, someone would take an order and travel to multiple locations throughout the nursery to fill the order. Now, Spring Meadow does “batch picking,” where they put all of the orders together and then pick the items by location for the entire week.

“It was very simple and quick way to reduce our No. 1 cost, which is labor,” said John. “Spring Meadow has 2.2 million sq. ft. of space to pick from, essentially—that’s all the buildings and greenhouses at just the main facility. So any time that you can eliminate those footsteps, you win in the efficiency category.”

Another major change was in the shipping area. When a greenhouse collapsed after a winter storm, it provided the opportunity to really build a more efficient space to move racks around, which was much more difficult with the gravel floors in the old greenhouse. Now the new shipping greenhouse includes a concrete floor with a conveyor system to move more product from place to place faster.

“When I first came here [11 years ago], we picked all of the material for the week, we laid it down, and then on Monday, we would pick it all back up, put it on carts and move it into a storage barn,” John explained. “With concrete, we could pack it right in place, so we eliminate all of those extra movements. Today, on a typical Monday, it takes about nine to 12 people to pack and we get essentially 50% more volume in six to eight hours. When we had the old greenhouse, we used to use 40 people and it would take us two days to pack just half.”

John said they also have a new software program that’s integrated directly with their freight carriers. They used to do everything manually—print the bill of lading and fill it out by hand—but now the new software does all of that with a few clicks. Remember when I said Spring Meadow has been tracking their productivity? It’s not just in propagation. John said it used to take seven minutes to process one order; now it takes 30 to 40 seconds.

“We try to make it all a math problem,” he said. “We know what our output is per day and how many orders come in. We figure out how many employees we need for this amount of hours and then move forward.”

Leaning in for the future

Spring Meadow continues its partnership with the folks at FlowVision, whether it’s for something small or something major. A year and a half ago, they were looking to build a new head house to serve as a production room for sticking and transplanting, and one of the first people Gail called was FlowVision to help them come up with the most efficient layout. She said they went through 25 different iterations before they decided on the right one.

“They just break it down simply,” said Gail. “Reducing steps. Not pre-working—you don’t build ahead because that just means you have to move things from Point A to Point B to Point C. That’s repetitive, not value-added. So it’s getting you to think—is your process adding value or are you just touching things that are just taking time? It’s coming up with a standard operating process and looking at how you can combine efficient, flexible positions so people aren’t standing around waiting 50% of the time.”

And starting in March, they’ll have computer monitors placed in the sticking and transplanting rooms to help track hourly output. These will replace the white dry erase boards they’ve been using to track employees’ progress and incentive goals.

“I think that it’s always good [to look at improving your processes]—especially when you’ve done something for so long—to get another opinion, a different way of looking at a process,” said John. “We all get very comfortable with what we do every day, but we have to embrace change. It’s a big sell to our crews, it’s a big sell for someone who’s maybe on the fence, but the benefits outweigh that. To do things better than you did last year, last week, or even yesterday, you have to be open to looking at things in a different way.” GT