1/1/2021

Pesticides, Water Quality & $$$

Dr. Sarah A. White

Pesticides are relied on to protect crops, manage weeds and reduce labor costs. Much of the time, the only factor considered when mixing a pesticide is how much active ingredient to add to control a troublesome pest. This strategy works in most cases, yet sometimes, the pesticide doesn’t work even though you mixed and applied it correctly. Why? Well, read on.

Pesticide degradation

Alkaline hydrolysis is a chemical reaction that occurs when a sensitive pesticide is added to water with a high pH. The degradation rate depends on solution pH, time in the spray tank (half-life) and temperature. Warmer temperatures (>88F/31C) increase the rate of pesticide degradation. To minimize potential for alkaline hydrolysis and ensure the efficacy of pesticide applications, you can manage spray water pH and application timing.

Pesticides and pH

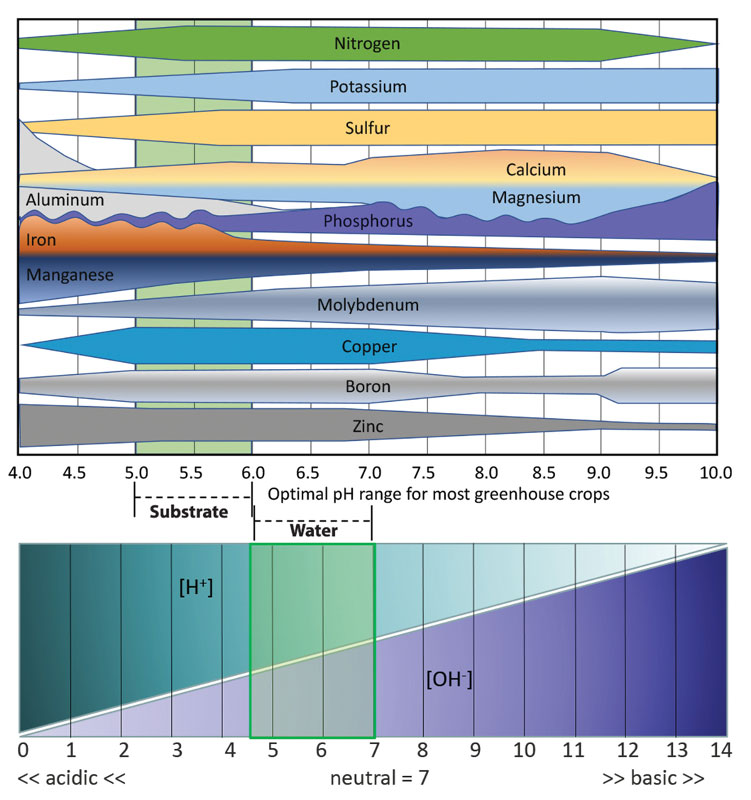

Let’s first discuss pH and why it’s crucial to know the pH of your water. Just like Goldilocks and porridge temperature (not too hot, not too cold), and fertilizers and nutrient availability in substrates (ideal range 5.0 to 6.0, Figure 1 top), some pesticides are more effective when the pH of the spray solution falls between 4.5 and 7.0 (Figure 1 bottom).

Figure 1. pH and nutrient availability in soilless substrates when growing greenhouse crops (upper image) and pH scale with the relative presence of hydrogen (H+) and hydroxide (OH-) ions as influenced by solution pH (lower image). Green shaded areas represent ideal pH range for substrates and water.

Images adapted by Sarah A. White.

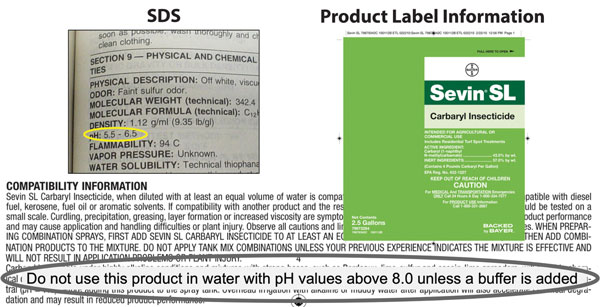

Most pesticides are stable when the spray solution pH is between 5.0 and 6.0. Some pesticides degrade if added to a solution with a pH greater than 7.0. Occasionally, the Safety Data Sheet (SDS) details the pH tolerance range of the pesticide (Figure 2). In other instances, the label might describe the stability of the pesticide in the Compatibility Information section.

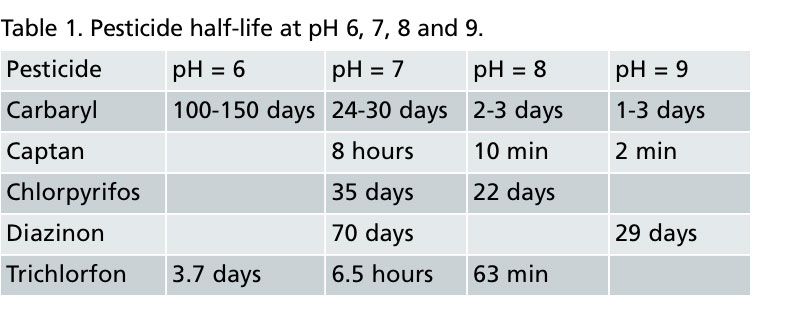

Pesticide half-life

Pesticide half-life

A pesticide half-life is the amount of time it takes for half the pesticide’s active ingredient to break down. Each half-life that passes reduces the amount of active ingredient in the water by one-half (i.e., 100% to 50% to 25%, etc.). The more the pH of the spray water diverges from the ideal pH range, the faster the pesticide will break down (Table 1).

In practical terms, have you ever mixed a pesticide for application and then not immediately applied it to a crop? If so, how did the pesticide perform? Was the control similar in the crop areas where you sprayed the product directly after mixing and after an hour (or more) delay? If the pesticide had a short half-life or was sensitive to pH, some or most of the active ingredient might have been lost to degradation while it was sitting in the spray tank.

Spray water pH

If you haven’t already done so, invest in some way to measure the pH of your water. Whether you use pH test strips (accurate within 0.5 pH units) or a calibrated handheld meter (accurate within 0.05 pH units), it’s essential to know and track your water’s pH. Water pH impacts pesticide efficacy and fertilizer availability (if pH is too high or too low various nutrients become less available, see Figure 1).

When is water pH suitable for pesticide mixing? In general, if water pH is between 4.5 and 6.0, it’s suitable for most spray applications and it’s okay to store the spray mix for 12 to 24 hours without loss of pesticide efficacy. This range isn’t accurate for all pesticide chemistries, as some pesticides (e.g., sulfonylurea herbicides) degrade if mixed into water with lower pH values (less than 6.0). If the pH range is 6.1 to 7.0, the solution is generally okay to use immediately or to store for use within one to two hours. If the pH is greater than 7.0, add a buffer, acidifier or both (depending upon the product mixed).

When is water pH suitable for pesticide mixing? In general, if water pH is between 4.5 and 6.0, it’s suitable for most spray applications and it’s okay to store the spray mix for 12 to 24 hours without loss of pesticide efficacy. This range isn’t accurate for all pesticide chemistries, as some pesticides (e.g., sulfonylurea herbicides) degrade if mixed into water with lower pH values (less than 6.0). If the pH range is 6.1 to 7.0, the solution is generally okay to use immediately or to store for use within one to two hours. If the pH is greater than 7.0, add a buffer, acidifier or both (depending upon the product mixed).

Figure 2. Example of a Safety Data Sheet (left) and product label information (right and bottom) that detail pesticide stability and pH.

Modifying water quality

You can modify the pH of your water in various ways and scales. Suppose you note issues with nutrient availability operation-wide. In that case, it might be time to consider injecting an acid (lower pH) or buffer (stabilize pH) to get the pH of water applied to crops into the range suitable for plant growth. If you simply want to modify the pH of water used for mixing pesticides, various buffering agents, acidifiers and water-conditioning agents are available. Talk with your extension agent or crop advisor to select the right product for your operation.

Check spray water pH and adjust with a buffer or acidifier BEFORE adding the pesticide. pH-sensitive pesticides start to degrade when they come into contact with a solution if the pH is wrong, even if you adjust the pH shortly after its addition. Not all pesticides react similarly to the pH of the spray water solution and some products shouldn’t be used with buffering agents. Always read pesticide labels for any precautions with respect to pH and potential product incompatibility issues. Apply pesticides soon after mixing and avoid leaving pesticide tank mixes in the spray tank overnight (even if your water pH is in the safe range).

Keep a log

Regardless if you have to modify spray tank pH or not, it’s wise to keep track of:

1) The pH of your water when you mixed the pesticide

2) When you sprayed it

3) How long it took to spray (was there a break in the middle of the spray application?)

4) What climatic conditions were like when you sprayed (windy, hot, humid, etc.)

5) Efficacy (how well pest was controlled)

These are likely all items you keep track of for your pesticide applicator license, but they’re also useful for figuring out what happened if a pesticide didn’t work properly.

Take-home points

• Check the label and Safety Data Sheet for water quality compatibility issues

• Test your spray water pH before adding the pesticide

• Modify the pH of spray tank water BEFORE adding the pesticide

• Spray immediately after mixing

• Keep a log

Please don’t hesitate to follow up with me, your local extension agent, specialist or crop advisor to learn more about managing water quality to ensure pesticide efficacy. GT

Dr. Sarah A. White is a Professor and Nursery Extension Specialist at Clemson University. She can be reached at Swhite4@clemson.edu.