6/1/2020

Managing Propagation Mist

James E. Faust

Mist is just one component of the propagation environment and a successful propagation program requires balancing the mist program with the temperature, humidity and light environment. So we’ll start with the premise that the cuttings are being kept at temperatures from 70 to 80F (21 to 26C) and the plants are receiving a daily light integral of 5 to 10 moles/day.

What does mist do?

Before the cuttings have roots, they cannot take up enough water through the stem to maintain normal plant functions, so mist reduces the rate of water loss from a cutting from the time of stick until sufficient rooting has occurred, and irrigating the growing media provides the necessary water for normal plant growth. This time is typically 10 to 14 days for cuttings of most herbaceous species.

Mist applied to cuttings reduces water loss by two methods: 1) by increasing the humidity in the surrounding microclimate and; 2) by evaporating and keeping the plant tissues cool. Mist doesn’t add very much moisture directly to the cutting because the leaves are covered with a waxy material that limits water uptake. Surfactants can be used to allow water to penetrate the waxy cuticle.

Mist isn’t the same as irrigation

Irrigation is the process of adding water to the growing media so that it can be taken up by the roots or by the stem for unrooted cuttings. The purpose of mist is not to add water to the growing media. If the growing media is getting wetter throughout a day of misting, then the volume of mist applied is excessive and is dripping into the media and accumulating. This is a common error. The ideal situation is to apply enough mist to wet the foliage and then reapply mist before the leaves are completely dry. A breaker and hose are used to manage the proper soil moisture content, while the mist is used to keep the foliage moist.

What’s the ideal soil moisture content?

Cuttings root best when the propagation medium is moist, but not soaking wet. Soaking wet is defined as 100% saturation, so the ideal moisture content is 85% to 95% saturation. Soil moisture content >95% will limit oxygen from diffusing to the base of the stem where root initials are formed. This will inhibit rooting. Soil moisture content <80% will result in wilting during sunny days and the leaves will be damaged.

How much mist does a cutting need?

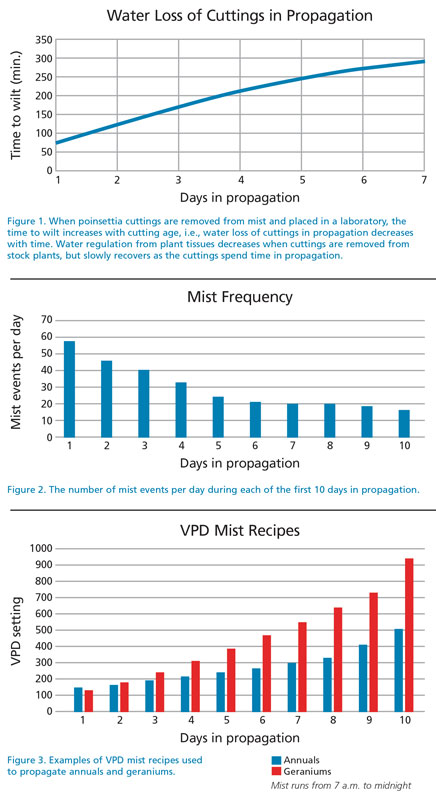

The answer to this question changes every day that the cutting is in propagation. When cuttings are harvested from stock plants, they lose their ability to efficiently regulate water loss, so the cuttings wilt aggressively on Day 1 in propagation (Figure 1).

In most situations, mist is required during the first night or two after sticking because the cuttings are “leaky” and have difficulty taking up water as rapidly as they’re losing it through transpiration. With each passing day in propagation, the cutting regains its ability to regulate water loss. Consequently, the frequency of mist required to keep a cutting turgid will decrease on a daily basis. Figure 2 demonstrates the change in the number of daily mist events that occur in a typical greenhouse during early spring propagation.

Mist frequency x Mist volume per mist event = Total water applied

The total volume of water applied during propagation can be calculated as volume of mist applied per square foot per mist event by the mist frequency (the number of mist events per day). The volume of mist is determined by the mist nozzle being used and either the duration that the mist runs or the speed of the mist boom. If a light mist is applied, the mist events must occur more frequently. If a heavy mist is applied, there’s more possibility that water will drip into the propagation media.

The propagator’s job is to properly balance the frequency and volume of mist so that the plants stay moist and turgid while the propagation media doesn’t become soaking wet (saturated). Excess mist will leach plant nutrients out of the media and promote algal growth on the media and walkways. No amount of biocide will control algae if excessive misting occurs during propagation.

The propagator’s job is to properly balance the frequency and volume of mist so that the plants stay moist and turgid while the propagation media doesn’t become soaking wet (saturated). Excess mist will leach plant nutrients out of the media and promote algal growth on the media and walkways. No amount of biocide will control algae if excessive misting occurs during propagation.

Perhaps the best technique for assessing the volume of mist applied is to peek underneath the propagation trays to observe how much water is dripping out of the bottom of the propagation medium. Ideally, just a drop or two of water are observed under each cell. If a pool of water is collecting beneath the tray, too much water is being applied.

Mist control systems

For commercial propagators, there are essentially four mist control systems:

• Time clock. The oldest system is a simple and inexpensive time clock. The grower determines when the mist starts in the morning, stops in the evening and the frequency of the mist events during the day. It’s not perfect, but it works, and millions of cuttings have been successfully propagated with this method.

The major problem is that the frequency of misting is set to keep the plants hydrated during the harshest portion of the day. Consequently, the remainder of the day (e.g., the morning and evening), the cuttings will receive excessive water that only results in problems.

• Computer-controlled time-clock. This is essentially a fancy time-clock. A computer-control system or programmable boom is programmed to have the day broken down into two or more sections.

For example, there may be a morning mist program, a mid-day program, an evening program and a night program. Each program is controlled by a simple time-clock control (e.g., mist on every 15 minutes), but the different programs allow the grower to adapt the mist frequency for the low and high demand portions of the day and night. This is the primary system used by the majority of large commercial propagators in the U.S.

Note that growers using the two above systems have a standard mist recipe that they’ll use and then they adapt the recipe to the ambient weather. If it’s cloudy, they’ll manually modify the settings from the standard recipe. To be successful, both of these systems require the propagator pay close attention to the weather and make manual adjustments throughout the day. Thus, time-clock systems require skilled and attentive growers to work effectively.

• VPD control. Mist systems can be controlled by the estimated amount of water evaporating in a propagation environment. These are termed VPD systems because the vapor pressure difference between the plant and the surrounding air is the driving force for water loss. High humidity and/or low temperature reduce the VPD and thus reduce the mist frequency. Low humidity and/or high temperature increase the VPD and thus increase the mist frequency.

An estimated 10% of large commercial propagators use VPD control. The beauty of the system is that the mist frequency is constantly changing to adapt to the constantly changing greenhouse environment. The propagator simply identifies the threshold VPD that triggers a mist event. This threshold changes every day from stick to rooting, so the propagator will have a recipe that has a unique VPD threshold for each of the first 14 days in propagation (Figure 3).

VPD control doesn’t remove the need for experienced oversight. Growers that have invested in and learned how to use VPD control systems tend to love them. VPD control makes the propagator’s job easier and more repeatable with each crop. Meanwhile, the growers that still use computer-controlled time clocks make the argument that they have an extremely high rate of success with their system, so why invest in the additional expense of VPD control? Why buy a Prius when my Ford Focus is still working quite nicely?

• Solar control. The least common mist control method uses a computer-monitored weather station to measure the light intensity delivered to a crop and then provide mist proportionally. Essentially, the weather stations “count” the light delivered to the crop and turns the mist on every time a certain threshold of light has been delivered. The principle here is that that evapotranspiration is closely related to the incident solar radiation. Like the other systems, it can work well, but is only as good as the person that’s overseeing the system.

The bottom line

It takes experience to be a good propagator. Propagation systems can make one’s job easier and allow the propagator to be distracted by other tasks throughout the day without risking severe casualties. Ultimately, any system is only as good as the operator.

A good propagation facility provides a uniform, moderated environment that’s not prone to harsh conditions, such as excessively high temperatures, a lack of bottom heat and drafts. Good water quality is also required (e.g., low EC water). Otherwise, even experienced propagators and well-designed mist control systems can struggle to overcome poor facilities or poor water quality. GT

James E. Faust teaches floriculture at Clemson University.