7/1/2019

30 Years of DIF

Julie Martens Forney

The year was 1984. Ronald Reagan was president, the first Apple McIntosh computer debuted and DNA fingerprinting became reality. In East Lansing, Michigan, a team of floriculture researchers working under the direction of Dr. Royal Heins were unraveling the interaction of day and night temperatures, average daily temperature and daily light integral on plant growth. This article focuses on how that work resulted in some of the most common ways today that growers control growth and reduce plant regulator costs in production.

Vic Ball, founder and editor-in-chief at GrowerTalks magazine, had been visiting the team at Michigan State University for years during his annual greenhouse travels. In a 1984 article in GrowerTalks, he reported some of the earliest results of the temperature-for-height-control work.

With Easter lilies, Vic noted that “low day temperatures materially shortened lilies. Conversely, a high day temperature with a low night temperature produces taller plants.” That difference between day and night temperatures would later become known as DIF.

Three decades later, DIF is accepted as common practice in the industry.

“It has become a matter of fact for growers,” said Roger McGaughey, Senior Head Grower at Pioneer Gardens in Deerfield, Massachusetts, and a GrowerTalks columnist. “It wasn’t always like that. I was one of the growers in Michigan that was able to work with Royal and his team. The basic concept—the difference between day and night temperature and how the plant reacts to that—has got to be paramount in any grower’s toolbox.”

What is DIF?

DIF is simply the difference (DIF) between the day temperature (DT) and night temperature (NT) that plants experience where they’re growing. If you put that into a math formula, it would look like this: DIF = DT – NT. Why is that important? Because plant height increases as DIF increases. Here’s how it works:

Positive DIF: When day temperature is warmer than night temperature that produces a positive DIF (for instance, 74F DT – 60F NT = 14F). A positive DIF promotes stem elongation—taller, stretched plants.

Negative DIF: When day temps are cooler than night temps that yields a negative DIF (for instance, 65F DT – 72F NT = -7F). A negative DIF suppresses stem elongation—shorter, compact plants.

Zero DIF: If there’s no difference between day and night temps, that’s a zero DIF— and stem elongation is

intermediate.

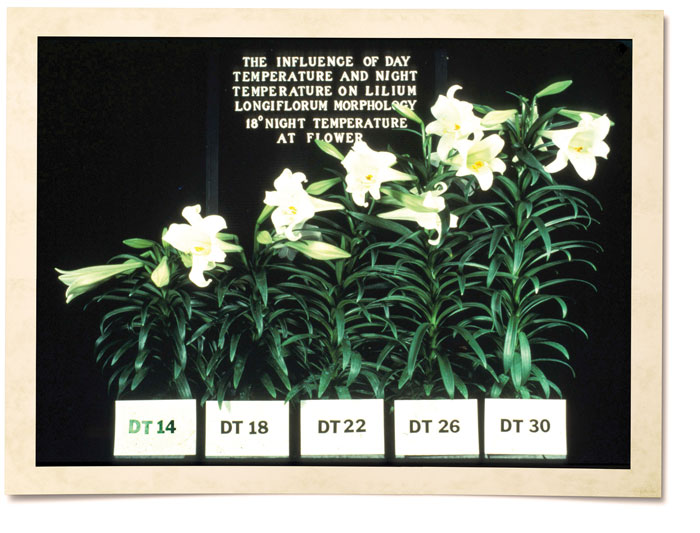

Pictured: See the effect of increasing day temperatures on Easter lily plant height at flowering. These lilies were grown at a steady 64F (18C) night temperature and increasing day temperatures from 57F (14C) to 86F (30C). As day temperature exceeds night temperature, positive DIF occurs and stems stretch. Photo courtesy of Dr. Royal Heins, circa 1986.

Pictured: See the effect of increasing day temperatures on Easter lily plant height at flowering. These lilies were grown at a steady 64F (18C) night temperature and increasing day temperatures from 57F (14C) to 86F (30C). As day temperature exceeds night temperature, positive DIF occurs and stems stretch. Photo courtesy of Dr. Royal Heins, circa 1986.

The bottom line is that plant stem elongation increases as DIF increases. By manipulating production air temperatures, you can control plant height in a way that doesn’t necessarily require growth regulators. For growers, that delivers an immediate savings—in dollars and chemical use. In this age of sustainability, any practice that helps reduce chemical use and labor costs is a very good thing.

When the research team first noticed how plants responded to day and night temperature, Royal was discussing the results with Andy Mast, owner of Andy Mast Greenhouses in Grand Rapids, Michigan. Andy wondered aloud if low day temperatures would work on Easter lilies to help bring a crop in on time at the proper height. Thanks to Andy’s numerous donations of Easter lily bulbs, the MSU team (which included then-graduate student and now professor Dr. John Erwin) determined that Easter lilies responded to day and night temperature. When John lined up plants, he noticed that plants grown with a similar relationship between day and night temperature were the same height. That is how DIF was discovered.

From DIF to DROP

The early work with DIF was promising and yielded consistent results—in university greenhouses. In 1987, it was time to take DIF into commercial production settings. That’s when DROP, or “morning drop” was born. Two growers were having trouble that year controlling Easter lily height using DIF.

One, despite using negative DIF treatments, wasn’t seeing shorter lily stems. Another was successfully using negative DIF to control stem height, but the cooler day temps were slowing overall plant growth—enough that the grower was worried about having the crop ready for Easter.

In the university setting, John was able to measure when plants elongated over a 24-hour period. He found out that most stem elongation occurred at the end of the night and the beginning of the day. That lead to the question of whether an abrupt temperature change to create the needed DIF at the end of the night and beginning of the day might be especially effective.

In the production greenhouse setting, growers were opening thermal blankets slowly at dawn to avoid a sharp temperature drop. At that point in time, all growers avoided abrupt temperature changes because it was considered bad for the plants. Quickly opening a thermal blanket and letting cold air slam into plants was heresy at best.

Pictured: Forced perennial Campanula carpatica Blue Clips shows the effects of DIF and DROP on plant height. The most compact plants occur when grown using negative DIF or DROP. Photo courtesy of Dr. Royal Heins, circa 1986.

Pictured: Forced perennial Campanula carpatica Blue Clips shows the effects of DIF and DROP on plant height. The most compact plants occur when grown using negative DIF or DROP. Photo courtesy of Dr. Royal Heins, circa 1986.

But at Royal’s urging, the desperate grower agreed to try it. The result paved the way for what’s now known as DROP or DIP. In this practice, growers lower air temperature around plants at dawn by 5 to 15F for two to three hours. The result? It’s similar to growing with a negative DIF: Stems don’t stretch. Better still, you don’t delay crop time as much as with cool temperatures all day.

“The shortest plants occur when they’re grown with a negative DIF all day, but the morning DIP does reduce stem height even if day temps exceed night temps later in the day,” John said. Royal and John were able to confirm this quickly with a group of 25 lilies; that work resulted in DIP.

Working with growers to solve industry problems is a hallmark of American Floral Endowment-funded research and DIF was no exception. The MSU researchers collaborated with growers who trialed the concepts, including people like Leroy DeVries, production manager at Henry Mast Greenhouses.

“Using temperature manipulation as a tool to control height literally changed the way we looked at crops,” he said. “DIF allowed us to reduce growth regulator use on many crops. Sometimes DIF is the only tool we can use to control plant height because growth regulators delay plant growth too much.”

Making it work

As DIF and DROP became widespread practice, growers fine-tuned the process based on regional and seasonal differences. For example, growers in cooler regions could successfully use DIF and DROP from winter through June, while growers in warmer areas (think Florida) might use it from mid-December to mid-March. John notes that in both cases, growers can let temperatures ramp down at the end of the night and keep temperatures cool the first three hours of the day and save on heating costs as well.

Another aspect that growers learned to tweak had to do with heat source. With plants grown on heated concrete floors, achieving the early morning DROP wasn’t really possible because the air around each plant’s shoot tip stayed warm. In this situation, a negative DIF couldn’t really be maintained, so growers relied on growth retardants to control plant height.

With naturally ventilated greenhouses without fan and pad cooling, cooling the air at dawn depends solely on convection flow. In larger operations, growers overcame these issues by segregating plants into temperature zones and applying DIF in houses with cooling pads.

Another issue growers encountered was that hanging baskets in the eaves of greenhouses experienced different temperatures than plants on the bench, resulting in two DIF figures in each house. In that case, many growers succeeded by using a higher negative DIF combined with either more growth retardant (on baskets only) or adding horizontal airflow fans to help equalize air temps at all levels inside the greenhouse.

As with any new technology, as growers used DIF and DROP, they uncovered—and tackled—the nuances, translating the tech into real-world practice. The bottom line that many growers agreed on in the late 1980s was that maintaining a zero or slightly negative DIF (especially in the morning) gave very effective height control. The other overwhelming conclusion was that DIF worked on all plant sizes—plugs, finished packs and pots—with or without an environmental computer.

Impacts of DIF

DIF created the proverbial ripple effect among growers who used it. Growth regulator use decreased and energy costs shifted downward as greenhouses adopted the early morning DROP.

“The air exchange with DROP adjusts the microclimate around plants, reducing humidity and helping reduce disease,” Roger said. Early morning DIP also exposed plants destined for outdoor gardens to cold pre-dawn temperatures, creating tougher, well-acclimated plants that should ultimately perform better in the consumer’s garden.

In terms of industry development, the timing of DIF research came just before buyers at the big box stores started issuing plant orders with precise date, plant height and flower specs. Up until this point, growers could get by with plants that were too tall or too short because buyers focused more on quantity. For instance, orders went from “65,000 poinsettias” to “65,000 poinsettia plants between 14- and 16-in. tall with seven flowers per pot on November 15.”

“Those precise orders led to endless headaches for growers who were trying to produce the perfect plant on the exactly right day,” Royal recalled. “DIF combined with graphical tracking was helping growers meet the challenges. As one grower said to me: ‘Now I can sleep at night.’”

Roger also cites another strong impact of DIF on crop growth.

“Using DIF properly, by taking plant measurements, forces you to go in and look at your crops,” he said. “It gives you a whole understanding of how plants function and what you can do to change them. Research like DIF and DROP that’s practically oriented has a tremendous impact in our industry and benefits everyone—the grower and the industry. If a consumer gets a lot of satisfaction from the products they buy, they’ll come back and buy more. That’s a win for everyone, and it starts with good growing practices like DIF.”

John mentioned that “growers can now literally change crop elongation rate daily with DIF and DIP. With PGR applications, growers lose that control and can sometimes over- or under-apply PGRs.”

The result of university research, DIF gives growers another viable option for controlling plant growth. “AFE has funded research projects like DIF that have transformed industry practices in production management and technology, pest management and postharvest handling for over 50 years,” said Terril A. Nell, Research Coordinator for AFE. “Every advancement is thanks to generous support from the industry.” GT

Plants respond to DIF or DROP growing practices in various ways. These plants respond strongly to DIF.

African Daisy

Ageratum

Aster

Astilbe

Basil

Begonia

Broccoli

Brussels Sprouts

Cabbage

Cantaloupe

Cauliflower

Celosia

Chrysanthemum

Coleus

Cosmos

Croton

Cucumber

Cyclamen

Dahlia

Dianthus

Easter Lily

Eggplant

Fuchsia

Geranium

Hypoestes

Impatiens

Italian Bellflower

Kalanchoe

Morning Glory

Oriental Lily

Pansy

Petunia

Polka Dot Plant

Poinsettia

Portulaca

Rose

Salvia

Snap Bean

Snapdragon

Streptocarpus

Sweet Corn

Sword Fern

Tomato

Verbena

Watermelon

Wheat

White Potato

Endnotes: Researchers who helped develop the DIF concept include: Dr. Royal Heins (retired, Michigan State University), Dr. Rob Berghage (Penn State University), Dr. John Erwin (University of Minnesota), Dr. Jim Faust (Clemson University), Dr. Paul Fisher (University of Florida), Dr. Meriam Karlsson (University of Alaska-Fairbanks), Dr. Roar Moe (Agriculture University of Norway, now deceased), Dr. Erik Runkle (MSU) and Dr. Will Carlson (retired, now deceased MSU).

University researchers like the team that developed DIF are eager to tackle industry issues. The American Floral Endowment (AFE) welcomes feedback and suggestions from the industry to help identify new key research needs. Also consider a tax-deductible contribution to the American Floral Endowment. It’s an investment with a terrific return. Industry-funded research benefits every grower when AFE is behind it. Reports on DIF and other AFE-funded research are available at endowment.org.

Julie Martens Forney is a freelance writer with more than 25 years of experience writing about floriculture industry issues and gardening for consumers. To read her current bylines, check out SAF’s Floral Management, HGTV.com and DIYNetwork.com. Julie’s also an avid gardener, tending edibles and perennials in a wildlife-friendly garden that features year-round color.