6/1/2019

Cutting Sticker Update

Chris Beytes

ISO Group Cutting Planter 2500

We last brought you an ISO Cutting Planter update in March, from the recent IPM Essen show, where ISO had touted their advanced software, Robovision AI, which uses artificial intelligence to “learn” more about the cuttings it’s planting and to get even better at sticking them. Since then, several growers have purchased machines to test on non-bedding crops, including heather (caluna), raspberry and even conifers, says International Sales Manager Raymond van den Berg.

The planting of heather, being successfully trialed by a German grower, is especially interesting, as the cuttings come from an automatic mowing of the crop, meaning they’re quite irregular in size and length. Robovision allows the machine to grade out cuttings that are too small or too large, only planting those that are within specs. And the more cuttings it sorts and sticks, the more it learns and the better it operates. Raymond says grading is becoming possible with more and more crops, thanks to artificial intelligence.

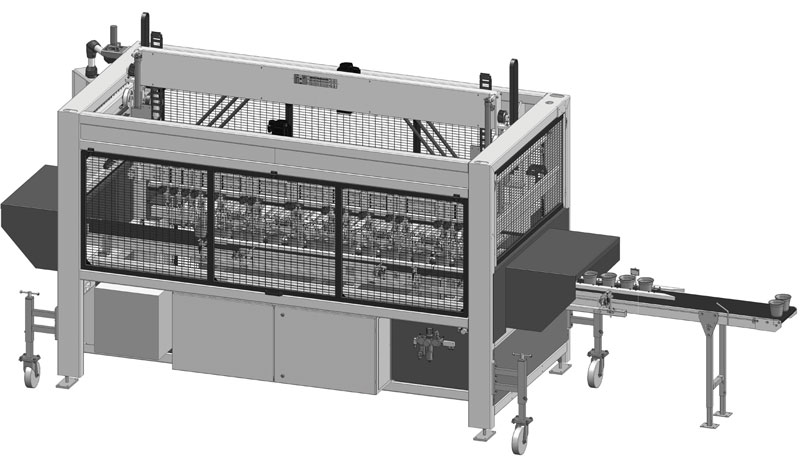

Pictured: ISO Group’s newest planter does bulbs for the cut flower industry. Photo courtesy of ISO Group.

ISO Group now has 130 machines in service, with 30 of those in North America. Raymond says they expect to have sold 150 by the end of the year.

What’s next for ISO? More interchangeable grippers to make the machine more versatile. They already have three additional grippers: One for cuttings that need to be stuck deeper, one for thicker cuttings and—even though no grower has yet asked for it—one that will plant individual AutoStix cells, such as Dümmen Orange’s Basewell or Selecta’s ROCS.

Oh, and bulb planting! At GreenTech in Amsterdam this month, ISO will introduce the ISO Bulb Planting System, designed to plant tulip bulbs into growing crates, as used by the greenhouse cut tulip industry. Hundreds of millions of tulip bulbs are hand-planted each year into growing crates—this will automate the process. It uses one computer and four robots, each capable of planting 2,500 bulbs per hour. A good employee can plant 3,000, says Raymond, but it’s hard on the back. With this new system, one or two workers can oversee two to four ISO Bulb Planters, capable of up to 40,000 bulbs per hour. There’s currently one machine in the field and three more to be delivered this year.

Visser AutoStix

In the same March issue of GrowerTalks, we ran a two-page photo in our “In Brief” news section on an AutoStix in use at Hampshire Farms in Illinois. What was newsworthy is that they use it exclusively for perennials—a new direction for the machine, which plants unrooted cuttings that are suspended by biodegradable plastic strips.

We also reported on the launch at IPM Essen of the AutoStix “Multi-Media” strip, which holds a bit of rooting media, the idea being an offshore farm can root cuttings right in the strip, which can then be shipped north for transplanting. Of course, that only works for countries that allow the importation of plants in media, which the U.S. does not.

Pictured: The brand new AutoStix 6GP, just unveiled this month in the Netherlands, is designed to plant into finished containers. Illustration courtesy of Visser.

The latest news from Visser, says Sales Manager Robbert-Jan in‘t Veld, is the launch of three new AutoStix models. The first, to be introduced at the aforementioned GreenTech show, is the AutoStix 6GP. Like the original, it’s a six-gripper unit, except it’s designed to be positioned in line with a carousel-style pot filler for sticking directly into finished containers—anything from small pots to hanging baskets. You’ll be able to plant from one to six cuttings in each container, in various patterns, so it’s perfect for making multi-color or multi-variety containers. It will use the same strips as the original machine.

The second machine, to be launched at Cultivate’19 in Ohio, will be a three-gripper AutoStix—basically a downsized machine suited for small and medium growers who don’t need the capacity (or price tag) of the original unit. Robbert says it will be a “reasonable price” for the smaller grower.

Lastly, the third machine will be a three-gripper version of the potting machine unit that will sit next to a pot filler. It’s for smaller growers who have a carousel-style pot filler and who want to stick cuttings directly into the final container.

“AutoStix is actually becoming the new way of transplanting,” says Robbert of the direction Visser is headed with the strip technology. “Our vision is that we have one machine at the grower that can be used for sticking unrooted cuttings, bareroot cuttings, soil-based rooted cuttings. And in the future, we’ll be adding more strips for larger liners as well.”

As for how many AutoStix machines are in the market, Robbert says 28, with 26 of those in North America. Visser expects to ship 10 to 15 more this year of the original unit.

The last thing we can say about cutting stickers is that we’ve gotten wind of a third competitor coming into the market. We can’t say who or when or with what exactly, but you can bet we’ll tell you all about it once they finally tell us! GT