4/1/2019

Keeping Your Herbs Under Control

Christopher J. Currey

Controlling containerized plant growth to produce plants that are aesthetically balanced is essential and culinary herbs are no exception to this. However, while floriculture and ornamental containerized crops can be treated with anti-gibberellin PGRs to keep them compact, there are no PGRs labeled for use on containerized herbs. Without any “silver bullet” to control crop size, containerized herb growers need to use multiple strategies to produce appropriately sized, marketable plants.

Crop scheduling

The first step in controlling growth is to schedule your crops. You’ll avoid excessive bench times by outlining, and following, an accurate production plan. Every extra day plants are held in plug trays or containers is another day of unexpected (and likely unwanted) growth, and minimizing or eliminating extra bench time will help you keep your crop growth in check and in sync with your target production plans.

Figure 1. Phosphorous is one factor promoting stem elongation. For example, restricting the amount of phosphorous provided to culinary herbs produces short, more compact basil and dill compared to plants provided the higher phosphorous concentrations usually applied during production.

Cultivar selection

The number of geranium, impatiens and petunia cultivars available is almost staggering, with appropriate genetics for almost any situation. While the number of cultivars available for culinary herbs isn’t on the same scale as floriculture crops, there’s still a range of herbs genetics for you to select from to control finished product size.

A great example of using compact cultivars for height control is dill. Traditional dill has a fast growth rate and can get tall quickly. While this may mean you hit your target height more quickly, the fast growth rate means you also surpass your target height just as fast. Using compact dill cultivars such as Fernleaf or Compatto provides you with a more compact finished plant that’s well-suited to containers.

Basil has, by far, the most cultivars available to choose from, including more compact cultivars that are well-suited to container production. Refer to the first article in this series (August 2018) for more information on cultivar selection.

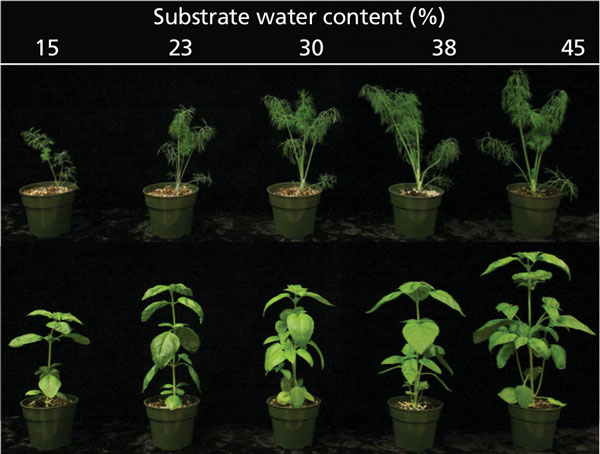

Fig ure 2. Restricting irrigation and growing culinary herbs drier can suppress growth. The dill and basil plants were grown in substrate maintained extremely dry (15%) to very wet (45%) throughout finishing.

ure 2. Restricting irrigation and growing culinary herbs drier can suppress growth. The dill and basil plants were grown in substrate maintained extremely dry (15%) to very wet (45%) throughout finishing.

Fertilizer concentration

Fertilization was discussed more in depth in a previous article in this series (December 2018). That article primarily focused on using fertilizers to meet tissue nutrient concentrations and produce deficiency-free foliage. We won’t review all of the content of that article, but there were two salient points pertaining to growth control.

First, using lower fertilizer concentrations [~75 to 100 ppm N for water-soluble fertilizers (WSF) or ~2 to 3 lbs./yd3 for controlled-release fertilizers (CRF)] allow for more healthy-appearing plants and minimize excessive growth during container production.

Additionally, growth of containerized herbs fertilized with CRF tends to be more compact than herbs fertilized with WSF. While CRFs can make fertilization easier, it’s harder to control growth, whether “pushing” or “slowing” crops, when using CRF. WSF fertilizers are easier to provide or withhold as needed during production.

Phosphorous restriction

Another effective method of height control is reducing phosphorous (P) concentrations. In addition to restricting P during seedling plug production, it’s also an effective method of suppressing height when finishing containerized herbs (Figure 1). As the P concentration increases from 0 to 20 ppm (0 to 45 ppm P2O5), plant growth (mass, height and internode length, etc.) increases linearly. Herb growth is generally maximized or saturates around 20 ppm P (45 ppm P2O5) and more P doesn’t promote additional growth.

You can’t simply eliminate all P from your finishing fertilizer program. With 0 ppm P, herbs will be severely stunted, the foliage will have signs of nutrient deficiencies and plants will be unmarketable. However, using 5 to 10 ppm P (~11 to 23 ppm P2O5) in your fertilizer solution during finishing will result in plants that appear healthy with a more compact appearance than plants provided with higher concentrations of P regularly when fertilizing containerized herbs.

Substrate moisture

Like fertilizer, you can use water as both the gas or brake pedal. Keeping plants well-watered pushes containerized herb growth and can maximize growth. However, when irrigation is restricted and plants are grown drier throughout production, herb growth is suppressed.

Herb species vary in the magnitude of response to being grown dry (Figure 2). For example, dill is more responsive to restricted irrigation, with proportionally greater growth control the drier crops are grown. Alternatively, growing basil dry results in only moderate growth control. Regardless of the degree of growth control, growing drier will have other benefits, such as less disease incidence and water use.

Growing dry has its challenges. The biggest challenge with dry growing is a crop can quickly go from being dry to being fried if a close eye isn’t being kept on plant moisture status and you neglect irrigating before crops suffer permanent damage.

DIF

The DIF is the difference between the day temperature (DT) and night temperature (NT) (DIF = DT–NT) and this directly affects stem elongation. The more positive the DIF, or the warmer the day and cooler the night, the more stem elongation is promoted.

Alternatively, as DIF becomes less positive, zero (the same day and night temperatures) or negative (a cooler day than the night), stem elongation is suppressed. This can be an effective method for controlling herb growth. However, it’s more economical to run a positive DIF, since it’s cheaper to heat during the day than the night.

A morning DIP can be an affordable alternative. The day temperature that the plant “registers” for DIF responses is right at sunrise. By dropping your air temperature below the night temperature, holding it there for the first few hours, then allowing it to raise to normal day temperatures, you’ll get a negative DIF response with a positive DIF heating bill. (See the article from February 2019 focusing on temperature for more details on this strategy.)

Mechanical control/brushing

Another non-chemical height control method is to brush plants. When plants feel force, whether wind or physical contact, they have a thigmotropic response, resulting in less stem elongation. By brushing plants with some flexible material, like shade cloth fabric or something more rigid like a PVC pipe or a wooden dowel, plants elongate less and are more compact (Figure 3).

Figure 3. While the crop getting brushed with this boom are containerized tomato and not culinary herbs, it can be a useful non-chemical growth control method. Keep a careful eye out for mechanical damage whenever brushing crops

The two biggest considerations with brushing crops are physical damage to plants and labor associated with application. Regardless of what you use to brush plants, you’ll want to take care not to brush so vigorously or quickly so as to cause physical damage to foliage.

The take-home message

Containerized herbs are a popular product, but controlling growth of these edible crops is more challenging than flowering ornamentals. Not only can herbs have a relatively fast growth rate, there are no chemical options for suppressing unwanted growth. The non-chemical growth control strategies outlined in this article present an array of opportunities to check growth and produce appealing containerized herbs.

Likely no single approach will provide you with all the growth control you need; however, aggregating as many of these approaches as you can will enable you to produce more compact herbs and grow a higher-quality product. GT

Christopher J. Currey (ccurrey@iastate.edu) is an assistant professor in the Department of Horticulture at Iowa State University.