2/1/2019

Managing Temperature in Herbs

Christopher J. Currey

Temperature affects growth rates, plant size and appearance of containerized plants, and culinary herbs aren’t an exception. Different aspects of air temperature affect containerized culinary herb production, but you can manipulate temperature to improve crop timing and quality.

Average daily temperature

The growth rate or rate of development of culinary herbs is controlled by the average daily temperature (ADT). There are three “cardinal temperatures” that can be identified when looking at the response of culinary herbs to ADT: The base temperature (Tb) is the temperature at or below which plant development ceases; the optimal temperature (Topt) is the temperature at which plant development is the greatest; and the maximum temperature (Tmax) is the temperature at or above which development ceases. Additionally, developmental rates at temperatures between Tb and T opt follow simple linear relationships—development increases with increasing temperature or decreases with decreasing temperature.

opt follow simple linear relationships—development increases with increasing temperature or decreases with decreasing temperature.

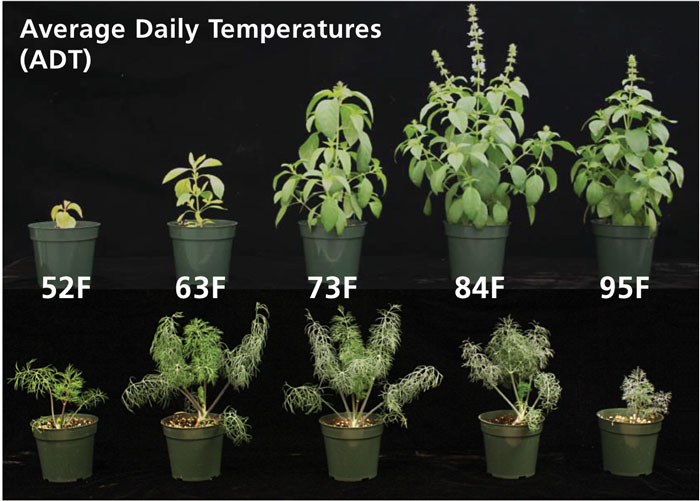

Figure 1. Lemon basil (Ocimum x citrioxdorum, top) and dill (Anethum gaveolens, bottom) grown at average daily temperatures (ADT) of 52, 63, 73, 84 or 95F for three weeks.

As we see across the variety of species in floriculture crops, culinary herbs vary in their response to ADT (Figure 1). For example, sweet basil (Ocimum basilicum), lemon basil (O. x citriodorum) and holy basil (O. tenuiflorum) are all warm-growing species, with an optimal temperature around 84F (28C). Alternatively, dill (Anethum graveolens), flat-leaf parsley (Petroselinum crispum) and cilantro (Coriandrum sativum) are moderate- to cooler-growing species by comparison.

The temperature requirements of several herbs are shown in Table 1 and serve as a general guideline for production. Crops can be grown outside of their recommended ranges, to a varying degree, depending on their sensitivity to sub- or supra-optimal temperatures.

There are a few ways to try and accommodate the different temperature requirements across your culinary herb crops. First, if different spaces with independent temperature control are available, you can group species by temperature requirements (i.e., warm-, moderate- and cool-growing species) and set temperatures accordingly in the different greenhouses. If you don’t have separate environments for the different temperature requirements, you’ll need to work to accommodate the variety in temperature requirements among your crops.

Look across all the herb species you produce and identify the different temperature requirements. Next, look at the proportion of space the different crops occupy. For example, basil (a warm-growing crop) is usually grown the most in any herb program. As a result, the air temperatures you choose may tend to favor basil compared to those cooler-growing crops that occupy a smaller proportion of both production space and sales.

Once you’ve selected your production temperatures, remember the linear range between Tb and Topt. That simple linear relationship—cooler temperatures slow down development and warmer ones speed it up—gives you a great tool to use to keep on track during production. Your ADT is both your gas and brake pedal, depending on how you use it.

DIF

DIF

One of the most important goals in containerized herb production is controlling growth and unwanted stem elongation. Several factors affect stem elongation and air temperature is one of them. The difference (DIF) between the day temperature (DT) and night temperature (NT) (DIF = DT – NT) affects stem elongation. As the DIF becomes greater or more positive (warmer day and cooler night), stem elongation is promoted, while as the DIF becomes less positive, zero (same day and night temperature) or negative (cooler day and warmer night), stem elongation is inhibited (Figure 2).

Figure 2. Sweet basil (Ocimum basilicum) grown at the same average daily temperature (65F), but with different day/night temperature combinations, resulting in (left to right) -10, 0 or +10F DIFs. Note how stem elongations are positively correlated with DIF—as DIF increases, so does stem elongation.

Using DIF can be an effective non-chemical method of controlling containerized herb growth. This is especially useful for culinary herbs, since there’s a lack of any chemical plant growth retardant labeled for use on culinary herbs.

One of the challenges with running a zero or negative DIF is the increased energy costs associated with running warmer nights with current fuel prices. An alternative is to use a morning DIP or DROP. This strategy involved running a traditional positive DIF regime: a warmer day and cooler night. However, just before sunrise occurs or electrical lights turn on in the morning, drop the temperature below your regular night temperature and hold it there for the first few hours of the morning, allowing the greenhouse to heat up to a regular temperature afterwards.

Using a DIP or DROP is more economical because you get the benefits of running a warmer day (capitalizing oin the greenhouse effect) and cooler night (minimizing heating during the coldest part of the day), reducing energy use and the associated costs.

Extreme temperatures

Extreme temperatures

In addition to managing the ADT and DIF, you’ll also want to avoid extreme temperatures. Damage can occur to plants when they’re exposed to extreme temperatures, whether exposure is isolated to chronic.

Chilling injury occurs when plants are exposed to damagingly cold temperatures, usually experienced around or below the Tb. As a result, culinary herb species vary in their susceptibility to cold temperatures.

Figure 3. Sweet basil (Ocimum basilicum) is a culinary herb that’s notorious for its susceptibility to chilling injury when temperatures are below 55F. The bronzing on the foliage is a common sign of chilling injury on basil species and cultivars.

For example, some herbs with low Tb, like dill and parsley, are less susceptible to chilling injury compared to species with a higher Tb, like basil (Figure 3). In a greenhouse facility, chilling injury is less common, occurring when there’s a failure in heating systems or plants are placed too close to drafty areas or the outer wall. After production, chilling injury can occur when plants are being loaded or unloaded onto trucks and are exposed to cold air, or in retail settings if they’re placed too close to entrances during the winter.

Exposure to extreme warm temperatures, or heat stress, is more common than chilling injury since warm ambient temperatures and strong sunlight during the summer make it challenging to sufficiently cool greenhouse facilities for extended periods of time. While warm temperatures can delay flowering for some floriculture crops, the vast majority of herbs are grown for their foliage and this isn’t a problem. However, warm temperatures combined with long days cause some species like cilantro (Coriandrum sativum) and dill to “bolt” or flower prematurely. Not only does this stop foliage production, it can also result in bitter-tasting foliage. Use shade, temporary or permanent, to help with temperature control during the summer for these sensitive species. Additionally, look for cultivars that are considered heat-tolerant and resistant to bolting.

The take-home message

Managing every aspect of crop culture and the production environment can be challenging. However, reviewing how you’re currently managing ADT, DIF and extreme temperatures may provide you with some opportunities to improve and fine-tune your containerized herb program. When making adjustments to air temperatures, try to anticipate how potential changes in your day and night temperatures will affect both ADT and DIF. By integrating the different effects temperature has on crops into your decision-making, you can better anticipate your expected results and minimize unintended consequences. GT

Christopher Currey (ccurrey@iastate.edu) is an assistant professor in the Department of Horticulture at Iowa State University.