2/1/2019

Injector Tune-Up Time

Lela Kelly

One of the only tools that can tell if your fertilizer injector is injecting accurately—meaning actually putting out the correct amount of fertilizer or pesticides—is a calibrated EC meter. These meters aren’t expensive, and when calibrated, will tell you if your injector needs maintenance. The growers I talk to tell me they check their fertilizer output at least weekly.

In order to produce high-quality plant material, how much you feed your plants matters. If your injector is in need of say, a seal kit, it may only be putting out half of the parts per million (ppm) it needs. By the time you see your plants aren’t thriving, it’s too late.

A basic seal kit change on most injectors shouldn’t take very long. (Check with your manufacturer on how to perform their maintenance and how often.) Most growers like to perform a routine seal kit change at least once a year. If you’re injecting mostly pesticides, like wettable powders, plant growth regulators or harsh cleaning products, be sure to change your seals two times a year.

Take a few minutes to read the installation directions if you’re not familiar with how to change the kits. Think about it like changing the oil in your car—as you put more miles on your vehicle, you change the oil more often. You would be shocked to know the amount of growers who contact us every year who have never changed a seal kit or checked their injectors for accuracy.

(Cost of maintenance: Approximately 14 cents a day on a 40-gal. per minute fertilizer injector.)

Need help? Have questions?

Most fertilizer injector companies have trained technical personnel standing by to assist you. Another resource is your horticulture distributor, usually the company you purchased the injector from. They can get you in touch with the manufacturer and they should carry the seal kits you need.

(Please note: If you’re using a piston-driven injector that makes a “clicking” sound as it operates, a seal kit won’t fix it. That clicking sound is the motor moving inside the injector. If it’s not clicking, it’s a motor problem and a maintenance seal kit won’t fix the motor.)

Should I clean my fertilizer injector?

Water quality definitely affects the performance of your equipment. We highly recommend the use of 200 mesh filters on all incoming water to the injectors (except reverse osmosis). Filters prevent fine sand or grit from damaging the insides. Good filtration is beneficial to all of your irrigation.

Hard water minerals will need to be removed from the inner workings of your injectors. It’s a good idea to dismantle the fertilizer injector the day before and soak it in citric acid, CLR or an 8-to-1 solution of white vinegar. (Always follow label directions and be sure to contact the injector manufacturer for what they recommend for their equipment.)

When injecting materials like organic fertilizers, biologicals or thick concentrates, be sure to clean the injector dosing parts often. It may be necessary to agitate your stock tank, and be sure your suction hose strainer that goes down into the stock tank isn’t sitting on the bottom pulling up undissolved particles.

Tips on using your fertilizer injector correctly

• Using a Standard Bypass Installation: A bypass for all in-line installations allows you to completely turn off the water to your injector. When you need to do any maintenance, this will let clear water go out to the greenhouse.

• Where to install the filter: Install a filter upstream of the injector, especially if you’re using T Tape. This will prevent clogging of your emitters. Many growers will also install another filter downstream of the injector for added protection.

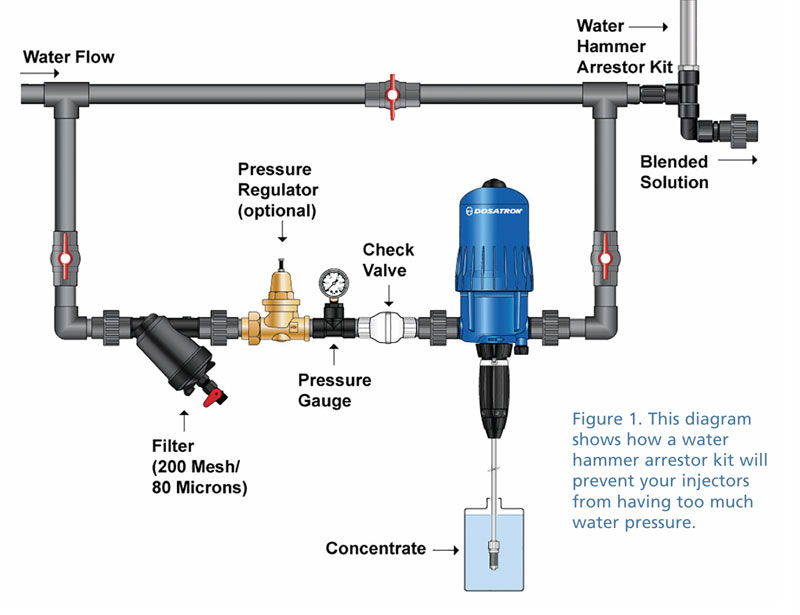

• Are you using solenoid valves? Solenoid valves installed downline of the injectors will close quickly causing water hammer. Water hammer will send a shockwave back to your injector three to four times the line pressure. If your line pressure is 50 PSI, that could mean 200 PSI will come back towards your injector and severely damage it. In order to prevent this, install a water hammer arrestor kit as shown in the diagram (Figure 1). Notice where it’s placed and how it’s installed. If you’re using a watering boom, this is extremely important. Most watering booms all use solenoid valves.

• Are you using the correct size fertilizer injector? All injectors have a maximum water flow rate in gallons per minute (GPM). Most growers have a hard time knowing what their maximum water flow rate is. This can be easily figured out by knowing how many hoses are used at once, or adding up all the drip tubes or nozzles in use at one time. Sometimes multiple zones can be running at the same time; all of this must be taken into consideration. If you try to run too much water through your injector, it will damage the motor and stop working, or it may not work correctly.

• Visit manufacturer websites: There’s a wealth of information available to you 24 hours a day on most websites. Look for instructional videos on how to do maintenance and change seal kits easily. Look up parts diagrams if you need to replace a part. You’ll find correct installation instructions to follow as well; there are great ideas on how to use your injectors you may not have thought of.

Maintaining your fertilizer injectors will make you money, not cost you money! GT

Lela Kelly is Vice President and Horticulture Specialist for Dosatron International, Inc. in Clearwater, Florida.