1/1/2019

Trays Too Dry?

Ryan Dickson & Rosa Raudales

Watering to the right substrate moisture level is critical for rapid and uniform rooting in propagation, especially during the first couple of days after sticking cuttings (Figure 1). Substrate that’s too wet or too dry can delay callusing and root initiation, promote disease and increase shrinkage (plants not sold).

Figure 1. New unrooted vegetative tip cuttings in propagation.

Many growers propagating in liner trays share a common watering problem—as the substrate dries it turns more hydrophobic (repels water) and it becomes difficult to wet before sticking. Trays can dry during shipping and storage, especially if not wrapped or covered properly, or when placed in too warm of a location (for example, next to heating pipes). If the substrate becomes too dry, growers may need to reapply wetting agent to restore water-holding capacity.

In a perfect world, substrate moisture across trays would remain uniform. In reality, trays can sometimes dry unevenly. Initially watering all trays the same can result in uneven moisture, and therefore, inconsistencies in rooting. Irrigating heavily and leaching is a strategy to make sure all trays have uniform moisture. However, this takes additional time and labor, and washes out pre-plant nutrients.

In this article, we discuss a case study in a commercial greenhouse operation in New England that implemented strategies to improve the uniformity of substrate moisture levels in liner trays during sticking of cuttings.

Commercial greenhouse operation

This operation propagated vegetative cuttings of spring bedding plants in liner trays containing paper-wrapped and loose-filled substrate. Trays were prepared ahead of time and stored on pallets, and were passed once through a watering tunnel set at medium speed just before sticking cuttings (Figure 2).

This operation propagated vegetative cuttings of spring bedding plants in liner trays containing paper-wrapped and loose-filled substrate. Trays were prepared ahead of time and stored on pallets, and were passed once through a watering tunnel set at medium speed just before sticking cuttings (Figure 2).

Figure 2. Propagation trays passed through a watering tunnel for the first irrigation.

Many trays appeared uniform in moisture, but some had a light-brown color and were lightweight when picked up, indicating low moisture. The following steps were used to improve consistencies in watering trays and substrate moisture level:

Step 1: Employees learned to determine substrate moisture level

Employees operating the watering tunnel and sticking cuttings were trained how to determine the moisture status of the substrate using a five-point scale, ranging from completely saturated (level 5) to very dry (level 1). Employees could differentiate when the substrate was too wet or too dry, and had a common language to communicate about watering and moisture status.

The five different moisture levels referred to substrate that was completely saturated (level 5), at maximum water-holding or field capacity (level 4), medium moisture (level 3), dry (level 2), and very dry or “bone dry” (level 1).

(For specific information on how these levels were determined and used, check out the previous GrowerTalks article “Too Wet or Too Dry?” by Dr. Paul Fisher of the University of Florida based on the moisture scale developed by Dr. Will Healy of Ball Horticultural Company.)

Step 2: Adjust watering practices according to starting substrate moisture

The next step was to see if passing the trays multiple times through the watering tunnel and at faster speed was an effective strategy to wet drier substrate and save time.

An on-site trial was conducted using extra 105-count trays of new paper-wrapped substrate sampled from several pallets. The initial moisture level was dry or level 2 on the five-point scale (common for their paper-wrapped substrate), light-brown color, lightweight and no drops of water could be squeezed out.

Half of the trays were air-dried on a bench in the greenhouse until they reached a moisture level 1. The substrate turned tan to grey color from lack of moisture, was very lightweight and shrunk in size. It also crumbled and resembled dust when squeezed in your hand.

Half of the trays were air-dried on a bench in the greenhouse until they reached a moisture level 1. The substrate turned tan to grey color from lack of moisture, was very lightweight and shrunk in size. It also crumbled and resembled dust when squeezed in your hand.

The trays passed through the watering tunnel twice and moisture level was checked after each pass. The watering tunnel speed was set at either medium (the normal speed setting) or high (almost twice as fast).

The growers wanted trays close to a moisture level 4 (field capacity and available water) at sticking to help keep cuttings hydrated. At moisture level 4, the substrate appeared dark brown, but had no visible free moisture on top. Water streamed out when liners were squeezed and trays bent under the weight when picked up.

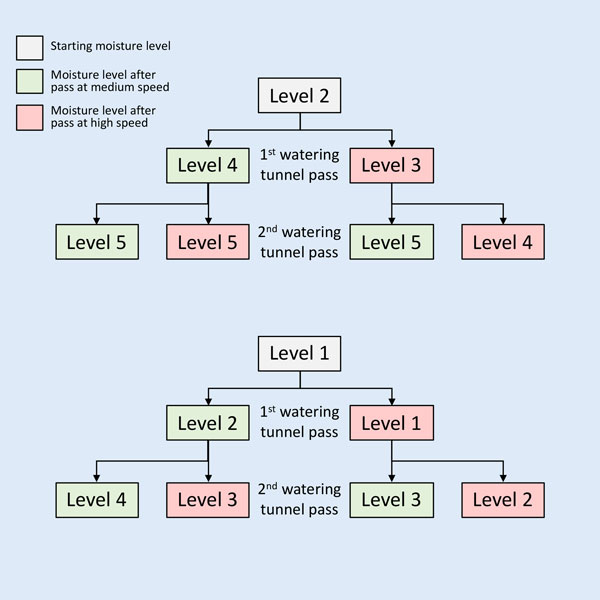

The diagram in Figure 3 shows the moisture level after each watering tunnel pass. With fresh substrate starting at moisture level 2, trays needed one pass at medium speed to reach a desired level 4. Two passes completely saturated the substrate (level 5) and was excessive, except for when both passes were at high speed, which also brought moisture to a level 4.

Figure 3. Watering tunnel passes and speed effects on substrate moisture level.

With dried substrate starting at moisture level 1, it took two passes at medium speed to bring moisture up to a level 4. Two passes at high speed, or one pass at high speed and one pass at medium speed, didn’t adequately wet the substrate. Several trays were also passed at a much slower speed setting (results not shown), but this only brought moisture to a level 3 and even one pass was too time consuming to be practical.

Step 3: Implemented quality control checks for trays going into propagation

The growers were interested in quality control procedures to check that trays going into propagation had sufficient and uniform moisture. At this operation, a separate area was used to stick cuttings, which were then loaded onto movable benches and transported to the greenhouse.

As a first check, employees quickly inspected trays as they came out of the watering tunnel and as they were loaded onto the benches to make sure they were close to a level 4.

Figure 4. Propagation tray placed on a weigh scale to check moisture level.

Figure 4. Propagation tray placed on a weigh scale to check moisture level.

As a second check, random trays were placed on a kitchen postal scale and weighed (Figure 4). Tray weight is mostly water—tray plastic and substrate weight is fairly constant and weight of the cuttings is minimal. Over time, the growers found for most crops that a 105-count tray of cuttings at moisture level 4 weighed at least 1.6 kilograms (3.5 lbs.) and this was used to spot-check consistency and double-check trays that felt too light. Target weights could also be determined for other tray sizes.

Conclusions

These growers took steps to help improve their watering consistency and reach target moisture levels when sticking cuttings. Employees were shown how to evaluate moisture level so they knew when the substrate was too wet or too dry. Simple on-site testing verified that watering tunnel practices may need to be adjusted depending on initial substrate moisture level and provided information on multiple watering tunnel passes and speed.

Finally, two types of quality control checks were implemented to help make sure substrate moisture levels were adequate and consistent for cuttings going into propagation. GT

Ryan Dickson (ryand@uark.edu) is an Assistant Professor at the University of Arkansas and Rosa Raudales (rosa.raudales@uconn.edu) is an Assistant Professor at the University of Connecticut.