12/1/2018

Going with Plan B … and C

Jennifer Zurko

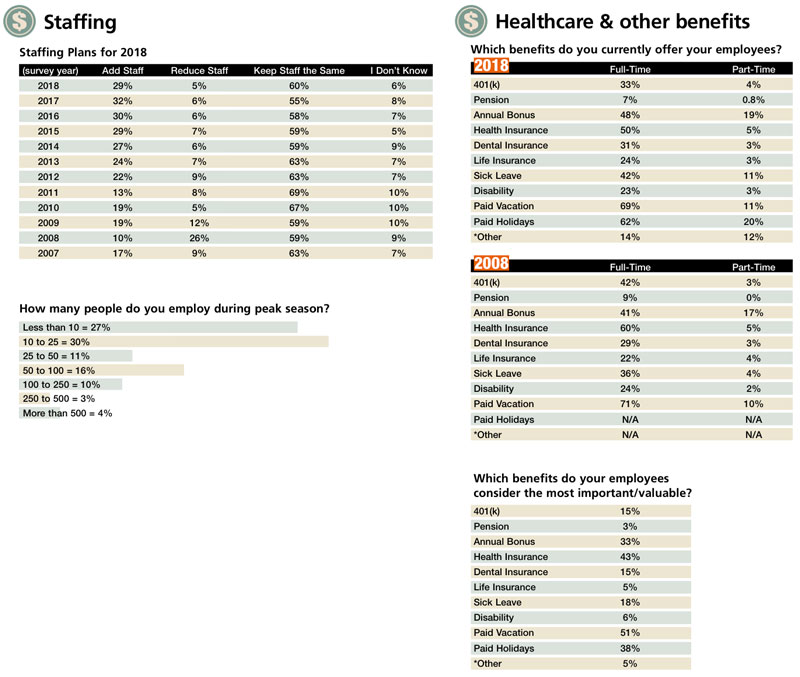

You can’t find people to work. We know this. Everyone knows this. So it’s no surprise that the number of operations who plan on adding staff for the upcoming season is starting to taper off a bit.

Maybe we’ve reached a tipping point to where, until the U.S. gets a guestworker and/or comprehensive immigration reform (if and when), the labor pool has plateaued. When the well is dry, there’s no point in lowering the bucket.

So what do you do when Plan A is no longer an option? Go to Plan B or C. In this case, it’s buying new equipment or paying a higher hourly salary or both.

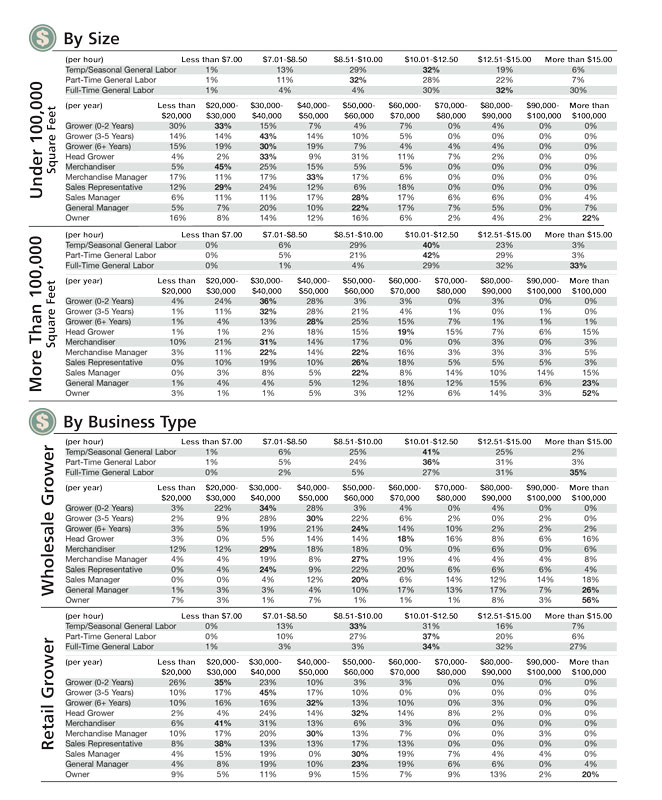

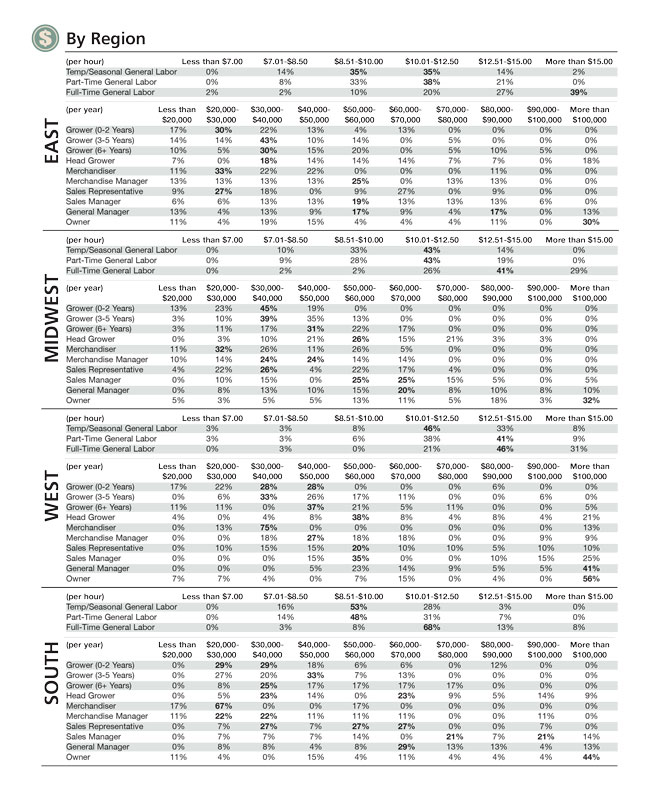

Compared to last year, three out of the four regions in the U.S. are saying they’re paying full-time general labor more than $15.00 an hour. Take the Midwest, for instance—in 2017, 18% said they paid full-time labor more than $15.00 an hour. This year, that number went up to 29%. Hourly pay for seasonal and part-time labor also went up. And in some areas, the annual salary has increased, too.

Along with paying more, we asked survey participants if they’ve had to invest in more automation as a result of the labor shortage and many said they have. A majority said they’ve bought equipment like soil mixers, plug transplanters, conveyors and flood benching, and upgraded irrigation and computer systems that some said cut out days to almost a full week of labor. If investing in a machine outright is too rich for your blood, one respondent said that they lease their equipment, which is a bit cheaper and easier to deal with when they need repairs.

Regardless of cash flow, it seems that many operations have come to realize that even the smallest or simplest greenhouse tool can make a difference when you’re trying to get plants out the door.

Here are some specific responses:

Purchased a Ditch Witch mini skid and multiple implements; moves plants, supplies and assists with all the display and landscape projects associated with displays and materials needed for our programing.

We have started using bulk soil, opposed to individual bags, thus increasing productivity by hours.

We have a flat filler and automatic transplanter. They allow our staff to focus on customers and other projects that broaden our inventory offered to customers rather than monotonous transplanting and filling pots by hand.

We are currently upgrading all our services and staff building so that they have a proper staff room (bathroom) and better work environment.

I continue to add “moveable benches” (32 ft. x 8 ft. hay wagons) to minimize handling. I added a bale shaver a couple of years back to minimize downtime while planting. I have owned a transplanter for close to 20 years and am looking to replace it before it dies.

Utilized more of the Seasonal Agriculture Worker Program and reduced contractors. Results are significantly better in overall plant quality, efficiencies and social atmosphere.

We use electric hand-held trimmers and an AgriNomix trimmer with blower/vacuum.

Bought new updated flat filler and bale processor with conveyor and using our Tagawa Punch-N-Grow for more planting options. This has increased production and downtime by doing this. Bought new tracking carts and had them made to the height of 32 in. that my employees wanted to reduce pressure on back muscles. Productivity has increased and my employees are happy.

We have started making extensive use of conveyor systems. Are trying to arrange for H-2A workers. Unemployment is less than 3% in our area.

We have just hired a Lean Flow company to help us become more efficient with our production and shipping labor.

We have some consultant services and headhunter services, as well as hiring temps. We also use temp labor from inmates in a local county prison. For facilities, we often contract out repairs and preventative maintenance work.

Robots to space, adding more watering booms, newer planting lines. More efficient ways of watering, planting, spacing. It is working great.

Worked with Lean Flow to establish some processes, which have allowed us to use cheaper labor during the busy season. It is working well.

Conveyers, ebb-and-flood floors, boom irrigation, Echo Basket systems. These tools are all becoming critical for consistent quality. [They] also help us cover more production area with less growers.

ISO sticking machines—we have five of them and they reduce our reliance on seasonal employees to do surge sticking activity by 25%. Staffing company—not very successful, as they are pulling from same people we are and they charge a premium. More efficient to have that done by our HR staff internally and add staff as needed to support that.

We bought the AutoStix machine to automatically stick cuttings to reduce the number of employees to process manually.

We bought additional material handling equipment, spraying equipment and automated irrigation in more areas. We hired weekend workers to help with production needs. We are still behind on basic nursery production tasks, including potting up, pruning and staking, tagging and moving or culling. We also shortened our business hours, tightened customer pickups to advance orders and scheduled times—reduced the number of varieties we offer and relied more on web-based availability and email communication.

We did purchase and rent more equipment in order to better utilize our headcount and invested in more training in order to create more skilled workers on our seasonal staff. I think it helped and we’ve had a great team this year. We worked with a temp agency to have backup, but did not use them in the end. The unpredictable nature of our very seasonal business continues to be a challenge to manage and we continue to try new things to improve our processes. 2019 will come with more process, training and equipment adjustments to find better ways to meet our needs and make a better and safer workplace.

“Other” included: Discount on merchandise; flexible schedules; fitness center dues; simple IRA 3% match; 4% holiday bonus pay; medical insurance reimbursement; free plants; family and medical leave; profit sharing; birthday off; floating holiday; tuition reimbursement; attendance bonus; referral bonus; free company apparel.

“Other” included: Discount on merchandise; flexible schedules; fitness center dues; simple IRA 3% match; 4% holiday bonus pay; medical insurance reimbursement; free plants; family and medical leave; profit sharing; birthday off; floating holiday; tuition reimbursement; attendance bonus; referral bonus; free company apparel.

Do What You Say

Do what you say you’re going to do—to establish an edge in hiring or in being hired, to differentiate your company as a hiring authority or yourself as a candidate, simply keep your word. Today's greenhouse candidate is carefully evaluating the major life-changing decision of joining your company. He or she is listening and watching, projecting himself into the role of employee, before the interviews have even begun.

In many cases, the potential candidate has many options, including the option of remaining at his or her current employer, plus there are other opportunities in multiple greenhouse industry niches: fruits, vegetables, all the ornamentals (starter material and finished), cannabis, vertically integrated nursery and even landscaping. On the other side, the hiring authority cannot afford the mistake of a bad hire and evaluates closely every interaction with the potential candidate.

Do what you say you’re going to do. On both sides ... If you’ve promised a résumé by such and such, deliver it. Keep telephone appointments. A promise of an answer on a specified day is a promise. It’s noted when that promise goes unkept. Be sensitive to confidentiality—not just candidate confidentiality—but the confidentiality of proprietary company information learned through the interview process. It’s a Golden Rule thing, and in this small town we call the international horticulture industry, it’s fundamentally, manifestly important. You’ll cross paths with everybody again.

There seems to be more outside investment money in the industry than ever before. It also seems much easier to raise investment money than to run a simple, honest, profitable, horticulture business. No matter if the business is old line or a result of new money, it won’t be long term unless current and potential employees are treated respectfully. Same with the candidate who has become an employee: if you want to be long-term, embrace your position enthusiastically with full commitment and interact respectfully with your employer. GT

Bob Zahra is an executive search consultant with Florasearch, Inc., a certified personnel consultant and past chair of the National Associa-tion of Executive Recruiters. He can be reached at (407) 320-8177 or bzahra@florasearch.com. Please visit www.florasearch.com.