1/30/2026

Cobots: Collaborating With Robots

Chris Beytes

Cobot. Shorthand for “collaborative robot.” An intriguing notion, and one that we at Inside Grower learned of only recently. Odd, really, seeing how the Wall Street Journal named “cobot” one of its “Words of Tomorrow” in its January 1, 2000 Millennium Edition. Which we obviously missed. Instead, we waited 25 years to hear it in connection with the Danish moving gutter system manufacturer Viemose DGS, which had announced a partnership with another Danish company, robotics firm 4XROBOTS, which specializes in adaptable pick-and-place robots—sometimes called “cobots.”

The very first cobot, named “Scooter,” had three wheels that could be programmed to help a human guide a heavy object into a confined space when assembling an automobile.

Assuming that neither Viemose nor 4XROBOTS coined the term, we dug deeper to see what we could learn about the cobots’ origin, use and potential, starting with one of inventors of the first cobot, Dr. Ed Colegate of Northwestern University near Chicago. The professor and his colleague Dr. Michael Peshkin were a pair of young associate professors in the mechanical engineering department doing a project for General Motors, developing robots that could safely share tasks with humans—tasks like guiding heavy, bulky dashboards into car interiors. Ed told us that the big issue with robots in a factory setting was the safety of the human workers.

“So originally our thought was that our robots will not be able to move themselves at all, but they’ll be able to sort of act like programmable guides. The analogy I always use is if I give you a marker and a whiteboard and say, ‘Draw me a straight line,’ you can do it okay. But if I give you a ruler, you can do it faster and better. And so our robots were kind of like programmable rulers.”

But they weren’t yet called cobots. Based on how he wanted them to operate, he had dubbed them “programmable constraint machines”—a name that a colleague from the marketing department made fun of. So they held a contest in their lab, offering a prize for a better name. Post-doc student Brent Gillespie came up with “cobot,” winning $50 for his effort.

Cobots today

Those early cobots grew large and expensive and designed to operate in the assembly line cells of auto factories, where every job was a one-off installation. But as technology evolved, lower-cost, off-the-shelf robotic arms became the desired form factor for all things robot—and cobot. We asked Ed to explain the difference.

“What makes it a cobot and not a robot is that it’s safe to be around people without a cage around it. And the way that they make it safe is primarily by having it not move too fast or having it be too strong,” he said. “And then, through some pretty nice control techniques, if it does run into you, it has sensors that detects that and it just stops.” He added that artificial intelligence has opened a new world of safety for cobots.

Are today’s collaborative robots actually that—truly collaborative? Not in the original sense, said Ed, whose research objective was robots that would actually share a job with humans, like installing a car windshield—the human pushing it into place, the robot steering it into position and handling the weight.

“These days, when people say cobot, all they mean is that you don’t have to put a fence around it. To the extent that it’s collaborative, what it means is that you can have the robots working side by side with human workers.”

Help with transplanting, packaging

Help with transplanting, packaging

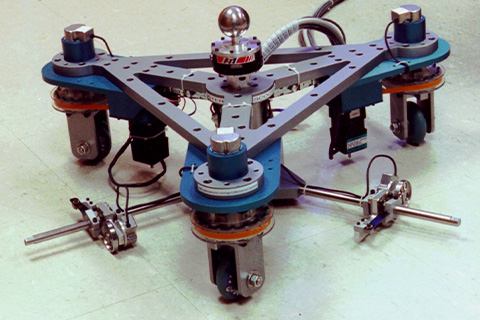

As mentioned, 4XROBOTS is the company that started this story. They market a style of robot called a delta, which has four thin arms suspended from an overhead motor drive mechanism. Their delta robots can move in three axes only—up/down, side/side and forward/backward, but can do so very quickly, making it ideal for planting or moving pots into or out of trays (“pick and place” it’s called), depending upon the gripper (called an “end-effector” in the robot world) you install.

4XROBOTS has installed one of their 4X Delta Cobots at potted plant producer Rosa Danica in Denmark, where it can pick and place up to 2,400 plants per hour alongside human workers.

Maria Gravesen, head of marketing for 4XROBOTS, told us that transplanting is the first task they targeted in the greenhouse, seeing it’s a repetitive job robots excel at, and labor cost and availability is a problem for every greenhouse. Their cobot is such that it can be deployed on any production line, alongside human workers, with little risk and no need for bulky cages. It only weighs about 75 lbs., so two people can relocate it to a new work spot. The unit comes with its own tablet for programming, and an electrical cabinet. It can also be linked to your other automated systems, such as a moving-gutter growing system, which is what their partner Viemose DGS offers. Maria said programming is as easy as guiding the arms from point A to point B.

Technology-wise, Maria said they chose to use sensors that register the location of the target pots and trays rather than cameras, to keep costs down. And the cost is low: about $30,000 plus the cost of the desired end-effector—she said that can be repaid in labor savings in six months to a year.

As for safety? The 4XROBOTS cobot is constructed of soft, lightweight materials, and if it does bump you, it will automatically stop. It has no pinch points. And if it does happen to hit something or someone hard enough, the arms are designed with break-away ball joints so the arms fall off rather than cause damage or get damaged.

Compared to existing automation

The industry already has automated machines that can transplant plants and even stick cuttings. So we asked Maria to explain the difference between the current crop of standalone machines that make use of an arm-style robot and their delta-style cobot.

“It’s still robotics,” she said of those other devices, “because there’s a robot in use, but it's an entire machine, you know—it’s fenced off and closed in.” Then there is the size of the investment—considerably more for the machine-mounted robot. And lastly, flexibility. With the cobot, “You can change the tool and make it a different pot size, or move into a different tray, or transplant a delicate flower or a succulent.”

While transplanting has been the area of entry for 4XROBOTS, vegetable packaging is a vast area of need, said Maria. In fact, her former employer, Universal Robots, a Danish pioneer in cobot technology, installed robots in Rosborg Greenhouses way back in 2018 to put packs of fresh herbs into boxes, both to save labor and to meet production quotas at peak times like Christmas and Easter.

A more challenging step for the cobot, of course, will be handling fragile produce and fruit. But Ed’s current area of interesting might help with that. He’s working on hands. Not five-fingered anthropomorphic human-like hands, but robot end-effectors with the dexterity and versatility of a human. And he wants to make it super-simple to program—using AI to make it almost plug-and-play.

Call them robots or cobots, machines for getting jobs done faster and easier are here to stay. They’re coming down in price and they’re getting easier to program. All you need to do is decide what to name him … or her. IG