10/31/2025

Getting the Best Response

Charlie Smith, Erik Runkle & Roberto Lopez

During the winter and early spring in northern latitudes, supplemental lighting is needed in the propagation environment to reduce rooting time and increase the quality of young plants. Many growers have adopted light-emitting diode (LED) fixtures due to the numerous benefits they offer over traditional high-pressure sodium (HPS) lamps. However, while high-intensity LEDs offer longer lifespans and higher energy efficiency than HPS lamps, they can also contribute to some unwanted responses in plants grown under them. One such issue is the development of purple foliage during propagation of cuttings that’s being reported on some crops by greenhouse growers (Figure 1). In severe cases, this discoloration can lead to crops becoming unsaleable.

Figure 1. Certain petunia cultivars propagated by cuttings may develop purple foliage five to seven days after stick when rooted under light-emitting diode supplemental lighting.

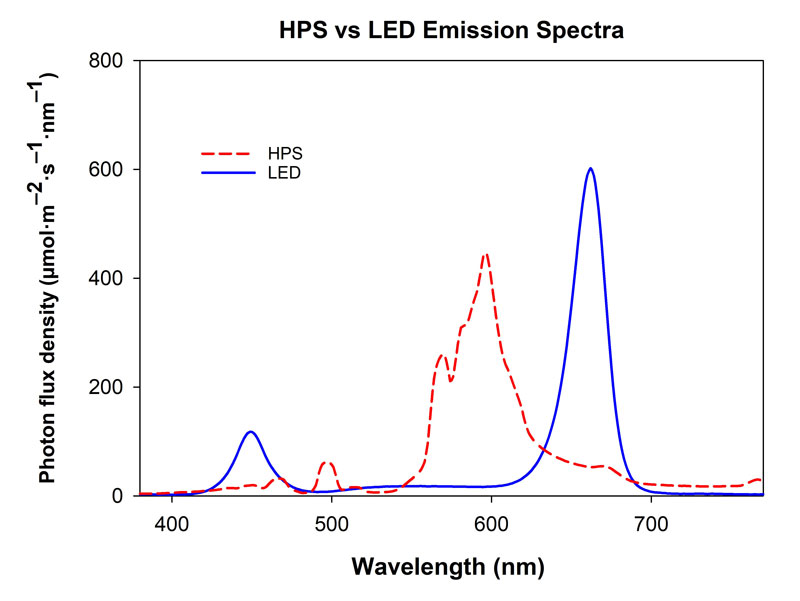

The purpling under LEDs highlights a key difference between LEDs and HPS lamps: their emission spectra or light quality output (Figure 2). HPS lamps emit high levels of green and yellow light, along with a relatively large portion of far-red (FR) and infrared light. LED supplemental lighting fixtures typically emit a high percentage of red light, moderate percentage of blue light and little or no green or far-red light. While this red light is extremely effective at driving photosynthesis compared to other colors of light, previous research suggests that blue light stimulates the production of anthocyanins, which are the red, blue and purple pigments found in leaves and flowers.

While these anthocyanin pigments can accumulate under ultraviolet radiation and blue light, high intensities of light can also cause leaves to produce anthocyanins and turn purple. This is important to note because as LED lighting technology has evolved the amount of light they emit has increased, resulting in the supplemental light accounting for more and more of the total amount of light delivered to a given crop. Therefore, the high-light intensity delivered by modern LED fixtures could also be contributing to this undesirable leaf coloration.

While these anthocyanin pigments can accumulate under ultraviolet radiation and blue light, high intensities of light can also cause leaves to produce anthocyanins and turn purple. This is important to note because as LED lighting technology has evolved the amount of light they emit has increased, resulting in the supplemental light accounting for more and more of the total amount of light delivered to a given crop. Therefore, the high-light intensity delivered by modern LED fixtures could also be contributing to this undesirable leaf coloration.

Figure 2. Comparison of the emission spectra of a high-pressure sodium (HPS) lamp and a typical light-emitting diode (LED) fixture used in a horticultural setting. Notice how the LED peaks in both the blue (400 to 500 nm) and red (600 to 700 nm) wavebands.

In addition to the influence of light, low temperatures can promote foliage purpling. Some of our previous work has suggested that raising air or root-zone temperatures to around 73 and 75F (23 to 24C), respectively, can help in preventing this purpling. Since HPS lamps emit a lot of infrared radiation, they increase canopy temperature. Under LEDs, leaf temperatures are often 3 to 5F (2 to 3C) cooler than those under HPS lamps.

Previous work under indoor sole-source lighting (without sunlight) has indicated that the addition of FR light can reduce the concentration of anthocyanins that accumulate in lettuce and other leafy greens. Considering this and the lack of research investigating the influence of FR light on foliage color during propagation, we designed an experiment to determine if the inclusion of FR light in LED supplemental lighting can reduce the onset of purple foliage in unrooted cuttings. We also wanted to see if a lower supplemental light intensity or the addition of root-zone heating could help prevent the unwanted leaf purpling when FR light is in the supplemental light spectrum.

The experiment

Cuttings of Petunia ×hybrida SureShot Dark Blue were propagated in a greenhouse with an average air temperature of 70F (21C). This cultivar was chosen because it’s especially sensitive to LED lighting during propagation. They were stuck into 72-cell trays filled with a peat and perlite mixture. Cuttings were provided overhead mist containing a water-soluble fertilizer. Once cuttings were rooted, mist was turned off and plants were manually fertigated. Vapor-pressure deficits of 0.3, 0.5 and 0.7 kPa were established for the first, second and subsequent weeks of propagation, respectively, with the injection of steam.

Cuttings were grown under one of two LED fixture types (delivering different light qualities) at one of two total photon flux densities (TPFDs) and with one of two root-zone temperatures (RZTs) for a total of eight different treatments.

Supplemental lighting treatments

Supplemental lighting treatments

One of the LED fixtures emitted a blue:green:red:far-red light ratio of 10:7:82:1 (Philips GreenPower TopLighting Linear DRWMB), while the other emitted a ratio of 10:18:59:13 (Philips GreenPower TopLighting Linear DR/W/FR_2 MB). The major difference between these fixtures was the amount of FR light they emitted. Specifically, the FR fraction (which considers the amount of far-red light relative to red and far-red light combined) of the latter fixture was 13 times higher than the former. Both fixtures emitted a TPFD of 120 µmol·m–2·s–1 at plant height. We had an additional light intensity treatment of 70 µmol·m–2·s–1. Plants grown under the high-light treatment received an average daily light integral (DLI) of around 8 to 10 mol·m–2·d–1, while those under the lower-intensity treatment received around 5 to 7 mol·m–2·d–1.

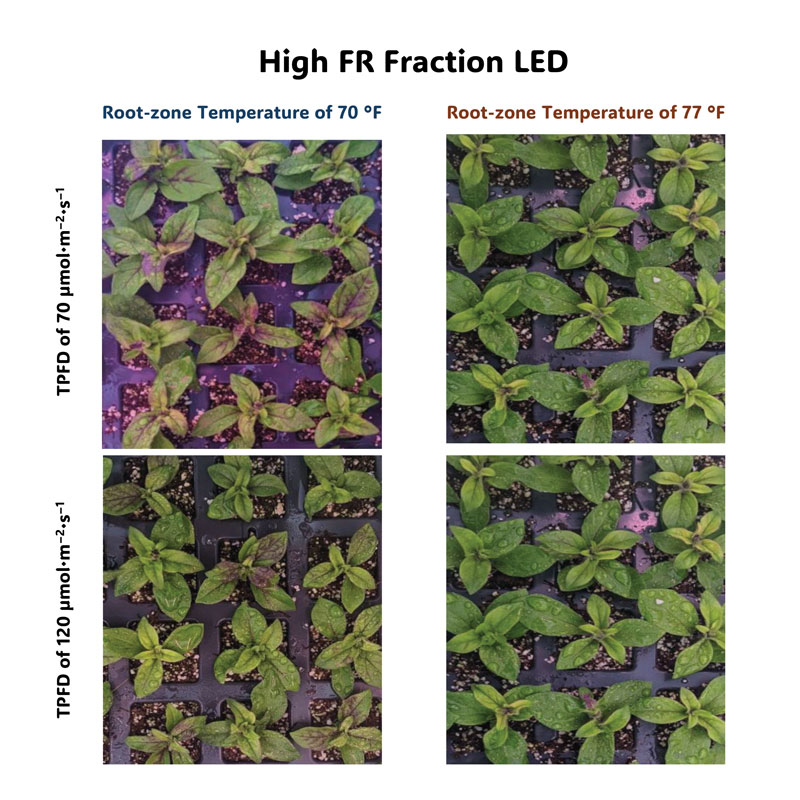

Figure 3. Petunia cuttings rooted under a light-emitting diode (LED) fixture emitting a blue:green:red:far-red light ratio of 10:18:59:13 at a root-zone temperature of either 70F (left) or 77F (right), and under a total photon flux density (TPFD) of either 70 (top) or 120 (bottom) µmol·m–2·s–1.

Root-zone temperature treatments: Each bench contained an embedded micro-tube root-zone heating system that circulated hot water to achieve a desired RZT. Cuttings were grown on benches heated to 77F (25C) and on unheated benches, whose RZT was around 70F (21C).

Data collection: Rooted plants were harvested 22 days after cuttings were stuck. Stem length and width data were recorded. To quantify growth, rooted cuttings were separated into roots and shoots, and the tissues were dried and weighed to determine the shoot and root dry mass. Additionally, total anthocyanin content was measured from leaf tissue of each treatment. Plant color was also quantified by measuring leaf redness to greenness and leaf yellowness to blueness of each treatment.

Results

Stems were slightly taller in cuttings propagated under LED supplemental lighting emitting the higher FR fraction. Additionally, cuttings grown under the lower-light intensity (TPFD of 70 µmol·m–2·s–1) tended to be taller than those grown under the higher TPFD of 120 µmol·m–2·s–1. Stems were usually thicker when cuttings were grown under higher TPFD. The stem dry mass was similar among all treatments. However, the root dry mass of cuttings was generally greater when grown at the higher TPFD.

Anthocyanin levels were higher in cuttings grown at a supplemental TPFD of 120 µmol·m–2·s–1 than in those grown under less supplemental light (Figure 3). Furthermore, cuttings grown without root-zone heating had more anthocyanins in their leaves than those grown with an RZT of 77F (25C). Leaves were more blue and red when grown under LEDs emitting a low FR fraction than LEDs emitting more FR light, at a higher TPFD than a lower TPFD and when grown without root-zone heating compared to an RZT of 77F (25C).

Key findings and recommendations

It’s well understood that plants grown under lower DLIs or under light with higher FR fractions tend to be taller than those grown under higher DLIs or less FR light. Not surprisingly, cuttings were shorter when grown under LEDs emitting a lower percentage of FR light or a higher light intensity. Therefore, if your goal is to inhibit stem elongation and keep plants stocky, increase the DLI by increasing the intensity and/or duration of supplemental light. Generally, once cuttings have begun to root, a DLI of 8 to 12 mol·m–2·d–1 is recommended to produce high-quality young plants that are well-rooted, compact and more resilient to shipping and transplanting.

Cuttings had little to no purpling when propagated under a supplemental TPFD of 70 µmol·m–2·s–1. While the LED spectrum didn’t have much effect on anthocyanin accumulation, cuttings grown under supplemental lighting with more FR light were generally less purple than those under less FR light. However, this slightly less leaf purpling wasn’t significant enough to necessarily recommend LED fixtures that emit a meaningful percentage of FR light.

The RZT was, by far, the most impactful variable we tested to prevent the leaf pigmentation and purple coloration of leaves. If possible, when propagating cuttings of sensitive cultivars and species under LED lighting, heat the root zone during the first six to 10 days of callusing and rooting to help mitigate this undesirable purpling. If you’re unable to heat the root zone, try lowering the intensity of LED supplemental lighting to a maximum of 80 µmol·m–2·s–1 for the first week or so of propagation. GT

Charlie Smith is a Ph.D. student, and Erik Runkle and Roberto Lopez are professor and associate professor, respectively, in the Department of Horticulture at Michigan State University. The authors would like to thank Ball Horticultural Company for cuttings, Signify for LED fixtures, East Jordan Plastics for liner trays, and Project GREEEN and the MDARD Specialty Crop Block Grant for financial support.