9/30/2025

Cool It With Your Crops

Jennifer Zurko

We don’t know what this winter will bring. We may get snow in Texas and Chicago could see temperatures in the 50s in December. Us folks up here in the northern part of the country are used to the colder weather, but as the last few years have shown us, the southern states can have a few days that reach as low at the teens.

We don’t know what this winter will bring. We may get snow in Texas and Chicago could see temperatures in the 50s in December. Us folks up here in the northern part of the country are used to the colder weather, but as the last few years have shown us, the southern states can have a few days that reach as low at the teens.

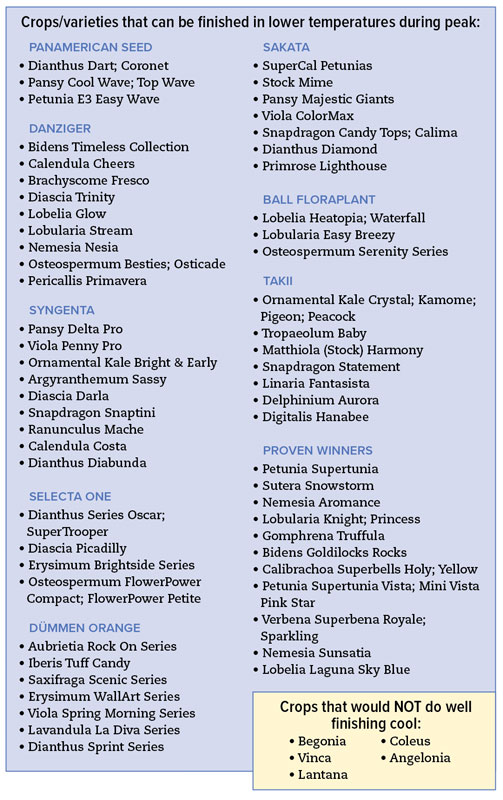

Of course, this is also during peak production time. Obviously, you still have to maintain those warmer temps during the plug and liner stage, but there are a handful of annuals that can finish up in a greenhouse with lower temperatures.

I sat down with Josh Henry, technical services specialist for Ball Seed, to ask him if finishing plants in a cooler greenhouse was worth the effort.

A caveat

As with many aspects of growing plants, there are many dependent factors when finishing at a lower temperature. Not just what you grow, but when you grow. Also, it depends on the degree to which you’re lowering your temperature. (Pun intended). Josh said that it’s not a black-and-white thing, it’s a scale.

“Every degree that you lower the average daily temperature is going to just slightly increase the crop time,” Josh explained. “So when you start making larger jumps, that’s going to add not just days, but potentially weeks to your total crop time.”

Josh said you need to weigh the pros and cons of lowering temperatures and adding crop time.

“Is that going to save on energy costs overall? It may or it may not, which is why you need to figure it out depending on your facility, your energy source, how efficient your facilities are. Things like that are going to make the difference of whether or not it’s worth it.”

Don’t just jump in with both feet

Taking all of those factors into consideration, you can conduct some trials with a few plants to see how they finish in a cooler house.

“That’s the fun thing about being a grower is you can try things out,” said Josh. “If you have an extra growing area off to the side, why not try it? You know, see how low you can go and still yield a quality crop in a timely fashion that saves you a little bit of money. I wouldn’t recommend jumping right into lowering your temperature 10 or more degrees and saying, ‘Yeah, let’s hope this works.’”

Josh suggested you use the growing information provided by the supplier as a base. If the culture sheets say 65 or 68, you start off in that range. Then as the plants get closer to maturity and you’re starting to see flower buds initiating, you know you’ve got some extra time. That’s when you can start dropping temperatures because it’s going to slow the growth rate.

So could finishing cool off-set or lessen the need for PGRs? Josh said it could.

“It can potentially be at least a partial replacement for PGRs,” he explained. “Again, it depends on the degree to which you’re decreasing your temperatures, but if your crop is finishing too quickly it may be another way to keep your growth a little bit more on the compact side.”

But don’t go overboard—there’s a minimum temperature you can’t go past. Even the leaves of a pansy will turn purple if the temperature goes below 50F (10C), which usually indicates a phosphorus deficiency.

Josh said another thing to consider is how frequently you vent. If you’re running cooler temperatures, you may be inclined to vent less to limit heat loss, but this can trap high levels of humidity, leading to limited transpiration and increased disease pressure. So, even if you’re trying to save on heat, you need to make sure to vent.

But then you have the humidity to contend with—sure, you could have a nice, cool environment, but not venting the heat out keeps the humidity in, which could increase disease pressure and lessen the plants’ calcium uptake. You may be saving on energy, but could be spending more money on fungicides. A lot of growers avoid this by using HAF fans to keep the air flowing.

Would this work for you?

Would this work for you?

It depends on the size of your operation and your market. A garden center that also grows their own product has a lot more flexibility to try things out on a smaller scale than a larger wholesaler who supplies to a big box store and has to hit a strict shipping target. But that doesn’t mean you can’t give it a go. Lower energy costs is a big incentive. It extends your growing season if you need it (like for northern growers who ship plants further south) and it keeps your greenhouse staff busy all year round.

And it could also give some of your plants a better chance of surviving early spring extremes, especially if winter decides to stick around a bit longer in some parts of the country.

“It’s more shocking for a pansy that was grown at 68F compared to a pansy that was hardened off down into the low 60s, high 50s,” said Josh. “It’s going to be a much easier transition for the one that was hardened off to go out into the landscape and then potentially survive really cold swings.”

There are a number of different options to help you maintain a cooler temperature in the greenhouse. Energy curtains will keep the environment relatively even, but you have to be aware of humidity levels. Bench heating is an even better option because you can potentially lower your air temperature a couple of degrees by maintaining a good root zone temperature, which we know is the “sweet spot.”

“You’re getting the heat delivered where it’s most needed in the root zone,” said Josh. “And it’s cheaper than heating the air.”

In the end, it boils down to calculating, trialing, paying attention and being flexible. Which sounds like a lot, but isn’t that what you do every day? If it saves you a bit on your energy bills and keeps your staff busy, it could be worth it. GT