1/1/2025

Cold Chain Management of Biologicals

Heidi Doering

Pictured: from left to right: ■ The ideal temperature range for holding each product is printed right on the bottle. Though each product has its own range, they tend to overlap in the 45 to 59F (7 to 15C) range.

■ When bios arrive, point and shoot the temperature inside the box with an infrared thermometer and write it on the packing slip. This catches any issues that may have occurred during shipping.

Biologicals, AKA natural enemies, include predatory mites, parasitic wasps, predatory insects and entomopathogenic nematodes—in other words, living creatures. In order to ship them to a grower, vendors use cold packs to slow down their respiration rate for travel, like suspended animation in sci-fi movies. When insects breathe, they give off heat and carbon dioxide, so they can actually suffocate their travel buddies if the temperature gets too warm.

Temperature awareness

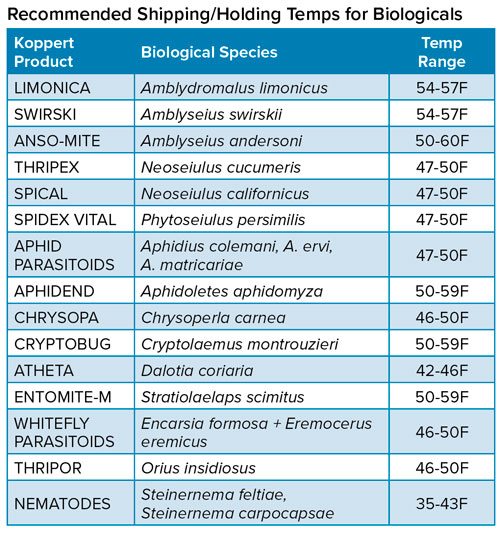

It’s important to be aware of the temperature at all times and to maintain optimal temperatures to keep the bios alive and well until deployment. For example, each Koppert bottle is marked with a small temperature icon that indicates its acceptable holding range. One biological product may have a best at temperature of 42 to 46F (5 to 7C) and another might be 50 to 59F (10 to 15C).

A common mistake to avoid: placing all products in the refrigerator when they arrive. Typically, biologicals like predatory mites, parasitic wasps and predators can be held in a temperature-controlled office—an area that’s typically kept at between 60 and 70F (15 and 21C). Growers with a cooler on the premises that’s set at 45 to 55F for bulbs or seeds, etc., can use it for holding when necessary. Generally, nematodes are the only beneficials that need to go into a refrigerator because they’re highly temperature-sensitive with a range of 35 to 43F (1 to 6C).

Aside from temperature, holding is the key word here. It’s never recommended to store biologicals over time. They should be on their way out into the crop as soon as possible, preferably within 24 hours of receipt.

When beneficials arrive

Don’t take it for granted that the cold chain is intact as the biologicals come through the door. Instead, always take a temperature reading inside the box upon arrival using an infrared (or other thermometer) and record that reading on the packing slip to confirm/document cold chain integrity upon receipt.

When a product arrives at a temperature significantly outside the recommended range it’s not necessarily a concern, but worth noting and sharing with your biological supplier. Take Swirski-Mite for example—it’s relatively heat tolerant. Swirski sachet boxes indicate that the ideal temperature is between 50 and 59F, but Swirski sachets can arrive at the greenhouse with a temp of up to 85F (29C) inside the vented box and have very little to no loss of efficacy. It depends on how long the box temps have been elevated during transit.

Holding the product

If biologicals arrive late in the afternoon as the staff is leaving for the day, hold those products overnight at as close as possible to the recommended range shown on the bottle/box. When left in boxes until morning, lay the bottles horizontally and keep the box lid cracked open to allow ventilation and air exchange. If there’s a dedicated, ventilated, temperature-controlled storage area on site, the bottles can be removed from the box and held on racks or shelving in a horizontal position overnight. Horizontal orientation is preferred, as a vertical position leaves a lot less surface area for the insects to come up for air, putting them at risk of suffocation.

Sorting and organizing is best done right away when the bios arrive, while conducting the product quality checks and temperature assessments.

Preparing for deployment

One final check of the temperature in the box on the shelf prior to deployment is recommended. Two checks—one at receipt and one at deployment—makes troubleshooting and claims management easier if any quality issues arise after application.

When cold chain integrity remains intact, the predatory mites may be cool or cold upon arrival and thus not highly active. If this is the case, wait an hour or so for the bottles to warm up to room temperature before releasing the mites into the crop. Prioritize releasing the live predators—such as Orius insidiosus and cannibalistic species such as Chrysoperla carnea—first, followed by predatory mites and parasitic wasp pupae.

Nematodes

Temperature-sensitive nematodes need to go into a refrigerator/cooler immediately upon receipt to be held in the range of 35 to 43F until mixed and applied. It’s extremely important to have a minimum/maximum thermometer in that fridge/cooler and to check it each time product is placed in or removed from storage. There must be no deviation out of the specific temperature range from the time the nematodes arrive in the refrigerator/cooler to the time they’re deployed, as once they wake up the process cannot be reversed.

This is because nematodes are, unlike other live insects or pupae, in a dormant state as they arrive. They can be stored rather than held because they have a shelf life of four to six weeks in a refrigerator/cooler. For the best efficacy at deployment, nematodes need to be at room temperature when mixed with room temperature water. Pull them out of the fridge about 20 to 30 minutes beforehand to minimize any shock to their system.

Sachets

Biologicals in sachet form have a different cold chain requirement. These are typically shipped in vented boxes to allow for adequate air exchange and to minimize carbon dioxide buildup during transit. To save on freight costs, two or three boxes of sachets may arrive taped together. If the team isn’t able to place the sachets in the crop for a day or two, separate the boxes and arrange them singly on shelves or stagger-stacked on a pallet or shelf to minimize heat generation between boxes.

Every sachet is a self-contained microenvironment, so growers have a bit longer time frame of 24 to 48 hours to get them placed in the crop.

Every sachet is a self-contained microenvironment, so growers have a bit longer time frame of 24 to 48 hours to get them placed in the crop.

Pictured: Boxes of sachets may arrive bundled together. Upon receipt, separate any boxes that are taped to each other to keep heat from building up between them.

Check the temp of each box of sachets when they arrive, as they generate heat during summertime shipments. While Swirski is relatively heat tolerant, some cool season predatory mites, including Amblyseius cucumeris and A. andersonii, may experience heat stress with the high temperature when shipping in warmer months.

Troubleshooting

Efficient cold chain management drives successful deployment of biological pest management solutions. With the exception of nematodes, don’t hold any biologicals for more than 24 hours before deploying and pay close attention to temperature when receiving and holding biological products.

For example, if you keep parasitic wasps for more than 24 hours they may develop from pupae to adults, which means that essentially they’ve deployed inside the bottle. If that bottle is taken out and opened in the crop it’s all good, but if someone accidentally opens it in the office and the adults fly out, those bugs are lost.

Typically, deliveries of bios are weekly and predictable so it’s possible to organize timing of applications around them. It’s also helpful to have a good working relationship with the delivery driver who handles the product. Let them know that bios are perishable and that packages shouldn’t be left sitting outside if the temperature is below 32F (0C) or above 70F (21C). Post a sign on the door indicating that all deliveries should be left inside. Alternatively, have a climate-controlled box outside the door where perishable shipments can be placed by the driver. GT

Heidi Doering is Koppert’s National Ornamental Crop Specialist, supporting growers in IPM for over two decades. To contact Heidi, email her at hdoering@koppert.com.