10/1/2024

Rethinking Your Fertilizer

Grant Johnson & Bruno J.L. Pitton

Controlled-release fertilizers (CRFs) are commonly applied in container plant production due to their ability to provide a steady nutrient supply while minimizing leaching losses. However, the method of incorporating these fertilizers into soilless substrates can significantly affect their performance, as damage to the CRF coating can release nutrients faster than intended. A recent study explores the complexity of mechanically incorporating CRFs, offering insights that could help growers adjust their practices for better nutrient management.

Understanding CRFs

CRFs are designed to release nutrients gradually, aligning with the growth needs of plants and reducing the risk of nutrients leaching into the environment. The goal is to match the release rate with plant uptake so that nutrients are available at the right time during the growing cycle. Manufacturers develop fertilizer granules that are coated in specially designed semipermeable membranes that regulate the release based on environmental conditions such as moisture and temperature.

CRFs are prone to breakage

Due to labor constraints, mechanical equipment is used to uniformly incorporate CRFs into substrate. Damage to the coating of CRF granules can occur as substrate with CRF moves through conveyor belts, chutes, hoppers and are mixed by tines or agitators. Broken CRF granules, or prills, of soluble fertilizer result in greater leaching of fertilizer because cracks in the coating allow water in and soluble fertilizer out.

So how does mechanically mixed media affect the release rate of the fertilizer and is there need for concern?

The study: Mechanical vs. manual incorporation

The research used Osmocote Plus 15-9-12 and compared its performance when incorporated mechanically through equipment at a nursery and manually into a soilless substrate composed of seven parts Douglas fir bark and one part washed concrete sand. The experiments were conducted both with and without lavender plants to assess the impact on nutrient leaching and plant growth.

To determine if CRFs were being damaged by mechanical incorporation, media was collected at a nursery that uses typical machine mixing equipment. The same media had CRF added by manually incorporating with gloved hands. Five-gallon pots were filled with one of the two media (machine mixed, hand mixed) and placed on stands that allowed for about 1 qt. of leachate to be collected during each irrigation. The leachate was analyzed for salt and nitrogen content to evaluate the impact of nutrient leaching. Half of the pots from each CRF incorporation method were planted with lavender plants and half were not.

To determine if CRFs were being damaged by mechanical incorporation, media was collected at a nursery that uses typical machine mixing equipment. The same media had CRF added by manually incorporating with gloved hands. Five-gallon pots were filled with one of the two media (machine mixed, hand mixed) and placed on stands that allowed for about 1 qt. of leachate to be collected during each irrigation. The leachate was analyzed for salt and nitrogen content to evaluate the impact of nutrient leaching. Half of the pots from each CRF incorporation method were planted with lavender plants and half were not.

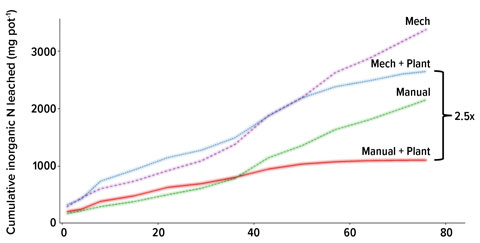

Table 2 shows the cumulative amount of inorganic nitrogen that was leached for both experiments over the trial period.

Plants uptake nutrients, so when plants are grown in the pots, more nitrogen is going to the plant and less is found in the leachate. This is expected. At the end of the trial, we can see this by the “Manual + plant” being lower than the “Manual” or the “Mech + plant” being lower than the “Mech” media.

What is even more interesting is that the beginning of the experiment shows that media with mechanically incorporated CRF is leaching at a higher rate than with manually incorporated CRF. Why is this? This suggests that the CRFs are damaged by the mechanical incorporation equipment during the substrate preparation process and greater nitrogen is leached from the very start. If there was no breakage of CRF coating, then the lines would not be so distinct.

Table 1. Hand-incorporated CRF resulted in lower values compared to mechanically mixed CRF, except for plant biomass, which was not different between the two media.

Table 1. Hand-incorporated CRF resulted in lower values compared to mechanically mixed CRF, except for plant biomass, which was not different between the two media.

Furthermore, media with CRF mechanically incorporated and planted had greater total nutrient leached during the entire experiment compared to the media with manually incorporated CRF. The planted media with mechanically incorporated CRF had more fertilizer loss than the unplanted with manually incorporated.

Focus on the “2.5x” in Table 2. Directly comparing planted containers of media with mechanically or manually incorporated CRF shows a two-and-a-half times greater amount of nitrogen leached. That’s a big difference and may indicate that nutrients are being wasted during the production cycle.

Focus on the “2.5x” in Table 2. Directly comparing planted containers of media with mechanically or manually incorporated CRF shows a two-and-a-half times greater amount of nitrogen leached. That’s a big difference and may indicate that nutrients are being wasted during the production cycle.

Table 2. Cumulative inorganic nitrogen content during the duration of the experiment. At the end of the trial, the manually mixed CRF media had lower nitrogen leaching compared to mechanically mixed CRF. The mechanically mixed CRF had about two and a half times more nitrogen leached than gently mixed CRF.

What to do

The method of distributing and mixing media with CRF incorporated can damage the prills and lead to increased fertilizer leaching and decreased nutrients to your plants. It’s important to be mindful of your own nursery operations and evaluate the compatibility of your equipment with the fertilizer you’re adding. If the electrical conductivity from leachate is greater than it should be, you may have damaged CRF prills in your media. Here are some options to protect CRF prills:

■ Last-in-line incorporation: Incorporate CRFs at the end of mechanized substrate mixing to prevent unnecessary damage to the prill coating.

■ Assess equipment: Regularly inspect and maintain mechanized equipment to minimize potential damage to CRF prills. Consider modifications or alternative tools that can achieve uniform incorporation without compromising prill integrity.

■ Monitor leachate: Implement routine monitoring of leachate EC and nutrient content to detect any anomalies early. This can help in adjusting practices before significant nutrient loss occurs.

■ Balance efficiency and precision: While mechanization offers labor savings and consistency, manual incorporation may be preferable in situations where precision and control over nutrient release are paramount.

■ Consider different manufacturer or coating technology: There are many manufacturers of CRFs and different coating technologies that may be a better fit for your equipment. If you find there are broken prills or fertilizer leaching above your allowable threshold, then consider having a discussion with your fertilizer providers.

Uniform incorporation: Evenly incorporated CRF within the substrate avoids localized nutrient excesses or deficiencies. This leads to predictable production uniformity in the growing bed.

Appropriate application rates: Adjust fertilization rates based on plant growth stages and environmental conditions to align nutrient availability with plant demand. Choose the nutrient ratio and release rate matched for your crop.

Consider environmental factors: Soil temperature and moisture levels influence the nutrient release rate. Warmer temperatures generally accelerate nutrient release, while cooler temperatures slow it down. Adjust application timing and rates accordingly to match plant needs and environmental conditions. GT

Grant Johnson is the urban agriculture technology advisor for Orange and Los Angeles counties, South Coast Research and Extension Center. Dr. Bruno J.L. Pitton is the environmental horticulture advisor for Placer and Nevada counties, University of California Cooperative Extension.