10/1/2024

RoBoCut: Autonomous Tissue Culture Propagation

Chris Beytes

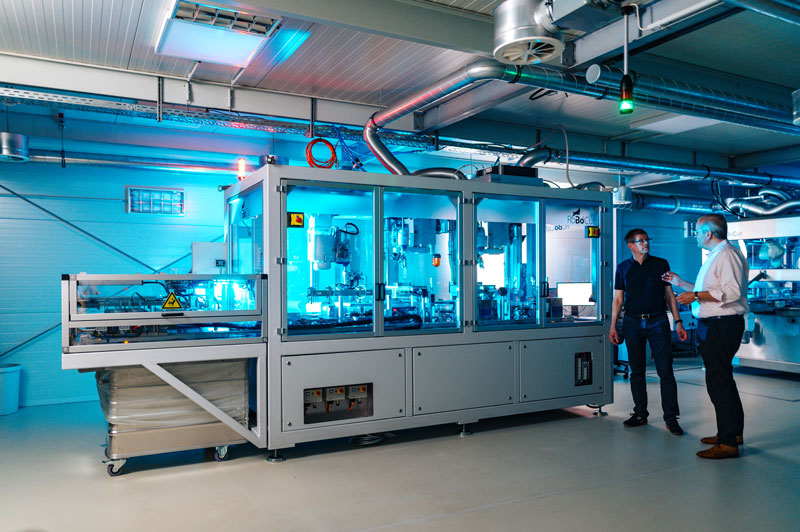

You’re looking at a self-contained, fully automatic tissue culture lab that fits in just a few square meters. It’s called RoBoCut and it was developed by the German tissue culture lab Bock Bio Science—more specifically by their division RoBoTEC, which they started a decade ago just for this monumental task of automating the in-vitro propagation process. RoBoTEC calls RoBoCut “the holy grail for in-vitro plant propagation worldwide.”

“The world needs more plants. There’s going to be up to 10 billion people that have to be fed by 2050. We can only do that by finding new technologies,” said Stephan von Rundstedt, co-managing owner of Bock and RoBoTEC with his wife, Friederike, an agricultural engineer.

In-vitro propagation—aka tissue culture or “TC” for short—is our highest-tech method of propagation. It can create thousands of identical plants from one bit of parent tissue, all in a test tube. But, despite that,

by trained specialists, who methodically work one container at a time. Manual labor is 60% to 70% of the cost of TC—nothing high tech about that.

RoBoCut is high tech. Internally, it has a quarantined environment; 3D image recognition controlled by AI; a laser (instead of a scalpel) for hygienically cutting apart the individual plantlets; precise and repeatable robotic arms; and a conveyor system that feeds sterile TC containers into and out of the machine. The software to control it all is beyond technical; in fact, about 80% of the development cost is in software, not hardware. The machine and software are protected by more than 50 patents.

Pictured: Friederike and Stephan Von Rundstedt, the dynamic duo behind the RoboCut.

Pictured: Friederike and Stephan Von Rundstedt, the dynamic duo behind the RoboCut.

After running many tens of thousands of tissue culture plants through RoBoCut, they’ve seen that plants recover faster and grow better when cut apart by a laser instead of manually by a scalpel, they say. Plus, the laser automatically sterilizes the cut surface, reducing the failure rate from 10% to 5%. Average cost per plant is one third that of manual tissue culture. Other benefits include the ability to run it 24 hours per day; repeatability and accuracy; control and security, since it’s onshore; and it reduces the overall production time.

Lest you’re thinking this is just for orchids and houseplants, know that ornamentals are just 20% of the overall TC market. Much bigger are agriculture and forestry (40%), and fruit and vegetable crops (35%). Cosmetics and medicinal plants make up the remaining 5%. Together, that’s a lot of potential users of this machine. Stephan says India alone needs 1.7 billion banana plants each year.

But if you’re a greenhouse grower or retailer, you won’t be buying one. So why should you care? Because RoBoCut has the potential to make it financially feasible to bring more plants to market in high-quality, disease-free tissue culture form. AND to do it at lower cost and to do it closer to the market. That’s a win-win-win for growers, retailers and the end consumer. GT

See a video of the machine in action on YouTube.