7/1/2024

Solar Appeal, Part 2

Eric J. Stallknecht, Richard R. Lunt & Erik S. Runkle

In the first article in the June issue of GrowerTalks, we explored the types of photovoltaic (PV) technologies that currently exist and described potential strategies to incorporate PVs into greenhouse structures. Incorporating traditional opaque PVs into a greenhouse will create additional shading that could reduce crop quality and yield.

However, light that’s intercepted can generate electricity for use on site and/or potentially sold back to the grid. Thus, striking a balance between transmission of light sufficient for crop growth while capturing light to generate electricity is essential for commercial implementation.

Ideally, the shade created from PVs would provide some benefit to greenhouse crops. PV technologies designed for greenhouses should incorporate crop-centric principles that aren’t currently well defined, but could include maximizing photosynthetically active radiation (PAR, 400 to 700 nm) transmission, decreasing high-temperature stress, flexibility to grow various crops throughout the year, limiting undesirable extension growth for ornamentals, maintaining desirable leaf pigmentation, and/or not delaying crop production time.

One promising way to utilize PV technologies into greenhouses is to incorporate newly emerging transparent solar panels as a replacement for common rigid glazing materials such as glass, acrylic or polycarbonate, thereby turning the entire greenhouse into one large solar panel. Semitransparent and transparent PV panels that absorb ultraviolet and near-infrared radiation to generate electricity while maximizing transmission of PAR could be ideal.

A collaborative research team at Michigan State University conducted a multi-year study to determine the effects of experimental PV panels on various greenhouse crops to inform future agrivoltaic greenhouse PV design. Here, we highlight the effects of several experimental semitransparent and transparent PV panels on the growth of red-leaf lettuce. We selected this crop because of its short production cycle, commercial importance and effects of light on leaf size, leaf pigmentation and biomass.

Experimental protocol

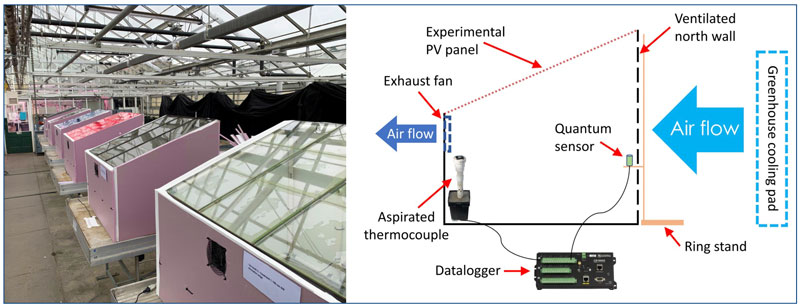

We constructed eight identical chambers, each approximately 10 sq. ft. (1 m2) and placed them on separate benches inside a glass-glazed greenhouse (Figure 1). The roof of each chamber was constructed with a different experimental PV panel and angled 20 degrees south. (The transmission spectrum for each experimental PV glazing material is displayed in Figure 2.)

Figure 1. Chambers with various experimental photovoltaic (PV) greenhouse glazing materials (left) and schematic of chamber design (right).

Adapted from Stallknecht et al. (2023a).

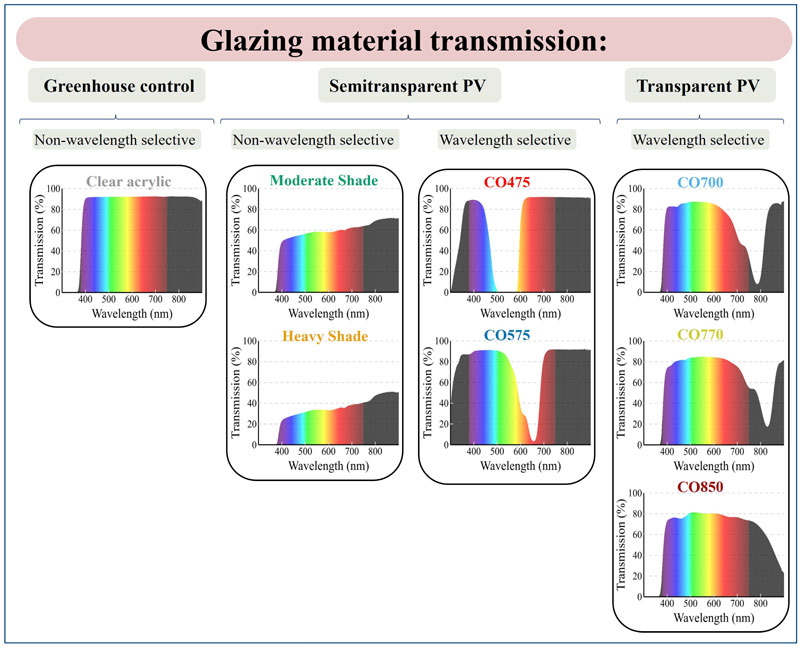

We compared a conventional greenhouse material (clear acrylic plastic) to four semitransparent (moderate shade, heavy shade, CO575 and CO475) and three transparent (CO850, CO770 and CO700) experimental PV panels. Each wavelength-selective panel had a unique absorption cutoff (CO) ranging from 475 to 850 nm. The CO value for each treatment is approximately the wavelength (in nm) when light transmission is decreased by 50%. For instance, CO475 absorbed a large fraction of light between 500 and 600 nm, while CO850 absorbed wavelengths longer than 850 nm.

Red-leaf lettuce Rouxai seedlings were grown from seed inside a controlled growth room for 14 days at 70F (21C) and a daily light integral (DLI) of 12 mol m−2 d−1. Once seedlings had two fully expanded leaves, they were transplanted on May 28 and grown until June 23 (26 days) at a density of 1.5 plants sq. ft. (16 plants m2). Fifteen plants per chamber were harvested for fresh mass and quality measurements.

Average air temperature and DLI were measured continuously in each chamber. The average DLI inside the chambers differed between treatments and ranged from 7 mol m−2 d−1 in the heavy shade treatment to 23 mol m−2 d−1 in the clear acrylic control chamber. The average air temperature inside each chamber was 73F (23C).

Results

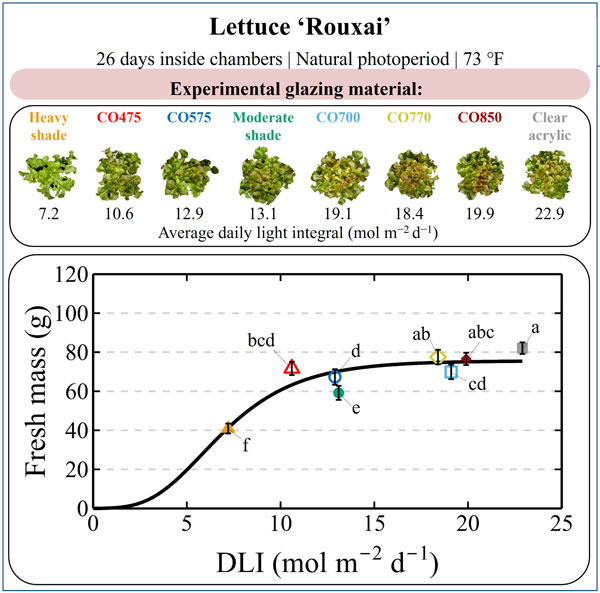

Semitransparent PV trends: An average DLI of 7 mol m−2 d−1 (heavy shade) was too low to grow a commercially acceptable head of Rouxai in 26 days. The low DLI caused elongated leaves, poor leaf color and relatively low fresh mass (Figure 3). The moderate shade, CO575 and CO475 panels, which transmitted an average DLI of 10.6 to 13.1 mol m−2 d−1, produced Rouxai with 10% to 26% less fresh mass and less red coloration than the high light, clear acrylic control.

Pictutred right: Figure 2. The transmission spectrum of each experimental photovoltaic (PV) panel.

Pictutred right: Figure 2. The transmission spectrum of each experimental photovoltaic (PV) panel.

Interestingly, lettuce heads had greater fresh mass and longer leaves under the wavelength-selective CO475 and CO575 panels compared to the moderate shade treatment with a similar DLI. Similar results occurred in snapdragon and basil. Thus, two different wavelength-selective PV panels could increase plant fresh mass compared to a non-wavelength selective PV panel, but this often comes at the expense of increased stem and/or leaf elongation. While lettuce fresh mass was lower under the semitransparent PVs compared to the clear acrylic control, semitransparent PV could still have applications as a greenhouse glazing in locations where the average DLI is greater than that of Michigan or potentially as seasonal shading material for crops tolerant of lower DLIs.

Transparent PV trends: Plants in these treatments received the highest DLIs and ranged from 18.4 to 22.9 mol m−2 d−1. Lettuce fresh mass under the CO770 and CO850 panels was similar to plants grown under the clear acrylic, but greater than under the CO700 panel. The CO700 panel had less transmission of far-red light than the CO770 and CO850 panels. Lower fresh mass under the CO700 treatment could result from: 1) far-red light driving photosynthesis and/or increasing the capture of light; 2) imperfect absorption cutoffs that consequently decreased the average DLI; or 3) a combination of the two.

Identifying an optimal cutoff above 700 nm—where the light is no longer useful to plants—is a critical research and development consideration for transparent PVs used in greenhouses. Our results suggest a cutoff between 700 nm to 750 nm has a minimal effect on lettuce fresh mass in comparison to a wavelength cutoff of 675 nm for transparent PVs in window glass for human vision. However, these results shouldn’t completely dismiss the potential use of CO700 because it decreased plant height and increased stem diameter of snapdragon, resulting in more compact plants. This indicates there are other potential benefits of PVs, such as to inhibit extension growth of ornamentals when fresh mass is less of a concern. It also highlights the need for panels to be designed with crop-centric criteria.

Figure 3. Lettuce Rouxai growth under different experimental photovoltaic greenhouse glazings as a function of average daily light integral (DLI). Plot symbols indicate means (n=15) ± 95% CI and letters indicate significant difference using Tukey’s HSD at α=0.05.

Figure 3. Lettuce Rouxai growth under different experimental photovoltaic greenhouse glazings as a function of average daily light integral (DLI). Plot symbols indicate means (n=15) ± 95% CI and letters indicate significant difference using Tukey’s HSD at α=0.05.

General trends: Lettuce Rouxai fresh mass increased as the average DLI inside each chamber increased, but in a non-linear manner (Figure 3). In the most extreme case, lowering the DLI from 22.9 mol m−2 d−1 (clear acrylic) to 7 mol m−2 d−1 (heavy shade) decreased the average fresh mass of Rouxai lettuce by 49%. In this study, biomass accumulation saturated around ~18 mol m−2 d−1. Similar to fresh mass, lettuce leaf color was progressively less red and greener when the average DLI was lower than ~18 mol m−2 d−1.

Overall, fresh mass and leaf color were primarily determined by the average DLI and secondarily by the PV panel transmission spectrum. Similarly, the average DLI was a more influential factor than transmission spectrum for snapdragon, basil, dwarf tomato and petunia. Based on these collective responses, we conclude that transparent PV panels that provided ≤25% shade were an acceptable replacement for a typical greenhouse glazing material during the spring in Michigan.

In summary, transparent PVs have the potential to be used as conventional greenhouse glazing materials, especially in high-light regions, and more seasonally in temperate climates such as in Michigan from spring to fall. However, in low-light regions, a decrease in the average DLI would likely have a detrimental impact on plant growth. Additional research is needed on a wider range of crops in different growing regions. Furthermore, the economics of PV panels will need to be explored once (semi) transparent materials are commercially available. GT

Eric Stallknecht is an Assistant Professor and Greenhouse Specialist at the Hampton Roads Agricultural Research and Extension Center at Virginia Tech. Richard Lunt is the Johansen Crosby Professor of Chemical Engineering and Materials Science at Michigan State University. Erik Runkle is a Professor and Extension Specialist in the Department of Horticulture at Michigan State University. This research was partly supported by the Horticultural Research Institute.