10/1/2023

Digital Crop Templates

Bill Calkins

A couple years ago, we ran a story titled “Measure to Improve” and introduced a method of planning, documenting, tracking and maintaining consistency in crop production. Two growers (and a former grower) presented this topic at AmericanHort’s Cultivate’21 event and explained how their operations build production templates that result in strategic direction, data collection, and immediate and longer-term improvements for each crop grown.

The feedback on the educational session and subsequent article was very positive and the reasons for using templates were clear. But the key request was for more detail on the templates themselves—how they’re created, shared and used. We reached back out to Matt Foertmeyer of Foertmeyer & Sons Greenhouse in Ohio and Bob Dickman of Dickman Farms in New York to dig deeper into the nuts and bolts of their production templates.

Why use digital templates?

Both Foertmeyer & Sons and Dickman Farms have had a system for saving crop data in place for about a decade, building formality into the process along the way. Bob explained that before true templates were in place at his greenhouse, crop notes were recorded in notebooks—with information inevitably lost from year to year.

“We needed to make sure that whenever a crop was grown in our facility, the same process was being followed,” he said. “We also needed production plan guidance for new growers.”

For Matt, the need for crop templates was realized during his time working for a greenhouse in Germany after graduating from The Ohio State University in 2007.

“I still remember the day the head grower at Westhoff shared with me the crop templates he used on all major crops,” he explained. “It almost felt like a rite of passage when he handed those documents to me.”

The importance of documenting every step of the growing process can’t be overstated, and when Matt returned to the family business the following spring, he immediately started using a small digital camera to take weekly photos of crops and began the process of creating formal crop schedules.

Keep it simple

Remember when the walls of your greenhouse office were lined with file cabinets? Maybe they still are … but perhaps at least a few have been tossed to the curb with the contents now residing on computers and phones. Some of those drawers, no doubt, held files on past crops and your growers could pull a folder and see some notes from years gone by. Unfortunately, there was usually very little consistency and plenty of gaps (not to mention the inability of new growers to decipher another person’s handwriting).

Those challenges (and space restrictions) are, thankfully, a thing of the past with new tools like Google Docs and other file-sharing platforms. The system used for storing and sharing crop template files really doesn’t matter, as long as it can be organized, easily updated and shared online for access via mobile devices.

“The system we use is really not that complex,” Matt said. “As a company, we use the Google Suite of software—Google Sheets, Docs and Drive.”

Each grower has access to the suite with a Google Sheets created for each major crop grown.

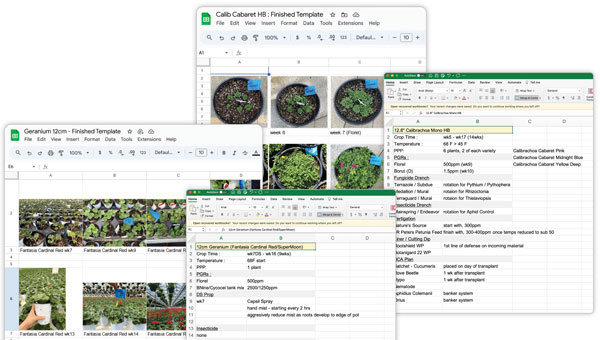

For example, there’s a Google Sheets created for “13-inch Calibrachoa Cabaret HB—Finished Template” and it includes three tabs, he said. The tabs include an overview, crop schedule and images. Each team member can access these sheets from their phones or laptops.

Bob explained that Dickman uses a very basic system that’s still analog, but moving to digital. A formal template is used for all crops, which can be printed off and filled out by section growers before the crop comes into their range. Once the crop is finished, the template is filed for reference the next season.

“Ideally, we will find a system that can be implemented into our smartphones,” he said.

Change is constant

The nature of greenhouse production is such that no two seasons are the same and each one provides many new learning experiences. As such, crop templates are most certainly “living documents” and must be revised and refreshed from year to year. Bob explained that there’s a lot of upfront work that goes into building crop templates and the greenhouse team at Dickman Farms worked on them for at least a month when they first started implementing the system.

“Now, it’s just about fine-tuning them,” he said. “We spend about a week prior to each season to ensure we capture all the data we need for the templates.”

Pictured: Crop template for 12-cm geranium production. Notice chemical applications are detailed, as well as when BCAs are applied. Photos from crop Weeks 7 to 16 are included for future reference.

Pictured: Crop template for 12-cm geranium production. Notice chemical applications are detailed, as well as when BCAs are applied. Photos from crop Weeks 7 to 16 are included for future reference.

• Crop template for calibrachoa hanging basket production. Note that plants per pot of each variety are recorded, along with full PGR regime and fertilizer plan. Photos from transplant though finish are included to help keep on track.

At Foertmeyer, Matt said it’s tough to quantify how much time is spent each year updating crop templates, but that the longer they’ve been growing a crop, the less time they spend tweaking the template. Templates are created for each new crop added to the product mix and the first year is somewhat of a guessing game.

“You talk to other growers, sales reps and look up online culture in order to create a starting point,” Matt said. “It’s safe to assume you’re going to make adjustments to these newer crops each season. I don’t think we’ve ever nailed a crop on the first try.”

He goes on to explain that one thing his growing team likes to do is (in a way) create two templates for each new crop. There’s often one or two adjustments that differentiates the templates, such as a different PGRs or multiple crop times.

“Our General Manager Annie Glaser loves to trial PGR rates on the new crops we grow,” Matt said. “She created two different strategies for a new salvia variety and treated each half of the crop differently.”

One half was treated with 5,000 ppm B-Nine and the other half with 2,500 ppm B-Nine + 750 ppm Cycocel. The 5,000 ppm B-Nine created a better crop and therefore that became the PGR standard on the crop template for that salvia variety.

Like any production experience you want to learn from and use to build upon in following seasons, one of the most important steps in the process is to debrief immediately at the end of the crop cycle and evaluate successes and failures with the steps on your template. Meet as a team and review each template to find any breakdowns and document them. That’s one of the best ways to make digital crop templates effective and capitalize on what they can provide.

What data to collect?

Here’s where you and your production team need to get together and decide how much or little information to record on each crop. Consistency is critical, but requiring too much information can lead to lack of implementation. Matt and Bob collect and record very similar amounts of information and feel all of the data is necessary for their greenhouse teams to grow consistently high-quality crops each year.

Since Foertmeyer’s three-tab system was mentioned above, let’s put the data recorded into those three buckets.

Overview:

• Crop finish time and plant week

• Starting temperature and ending temperature

• Plants per pot

• PGR strategy with rates

• Fungicide strategy with rotation

• Insecticide strategy (if applicable)

• Fertigation rates

• Biological control agent plan

• Liner or cutting dip (if applicable)

Schedule:

• When temperature was adjusted

• When PGRs, fungicides or insecticides were applied (including rates)

• When fertilizer rates were adjusted

• Other actions, such as pinching, trimming or moving to another growing location

Images:

• Weekly images of the crop

• Closeup of individual pot

• Wide shot of tray

• Images of plants at the stages where PGRs/pesticides/biologicals were applied GT