7/1/2023

Re-thinking Your Growing Media

Jeb S. Fields & Kristopher S. Criscione

Growers have relied on peat moss as a primary substrate component for decades, due to exceptional physical characteristics, which maintain an optimal rooting environment for containerized crops, particularly when incorporated as a primary component of a blended substrate. Not only does peat support improved water-holding capacity, but it provides adequate air-filled porosity, allowing relatively easy air exchange during and between irrigations. Additionally, peat moss has desirable chemical properties, including a low pH, which enables growers to freely manipulate as desired for their specific crop.

There’s a growing interest across horticultural operations to reduce peat use for various reasons. Growers are, therefore, pressured to seek alternatives and lower their peat footprint. You’ve likely heard of many of these “alternative” materials—such as wood fiber, coir, bagasse or even some composts—and many of you use these in some aspects of your operations. While these are important and beneficial options, re-imagining the entire container-substrate system may present an out-of-the-box type of solution.

A new type of substrate system

The modern container-substrate system was defined in the 1960s when soilless substrates production began its journey. The differences between container-substrate systems then and now are using or incorporating different materials with superior economical or bio/physio/chemical properties to already existing substrates. That is, a substrate used as a standalone or a substrate incorporated with amendments/alternatives blended uniformly and placed in a container. Thus, for the last 60 years, we’ve been using a similar structured substrate system. However, reimagining the container-substrate system may require steps beyond searching for alternative materials, such as engineering the substrate profile. Exploring new soilless substrate systems may also provide grower solutions for peat access, as well as some added water, fertilizer and productivity benefits.

Soilless substrate stratification is a relatively new form of substrate engineering being developed in the Fields Lab at Louisiana State University Agricultural Center in conjunction with Dr. Jim Owen, a USDA-ARS Scientist in Wooster, Ohio. It entails vertically layering or stacking different soilless substrates with targeted physiochemical properties atop each other within a single container, as opposed to filling the entire container uniformly with a single substrate.

Soilless substrate stratification is a relatively new form of substrate engineering being developed in the Fields Lab at Louisiana State University Agricultural Center in conjunction with Dr. Jim Owen, a USDA-ARS Scientist in Wooster, Ohio. It entails vertically layering or stacking different soilless substrates with targeted physiochemical properties atop each other within a single container, as opposed to filling the entire container uniformly with a single substrate.

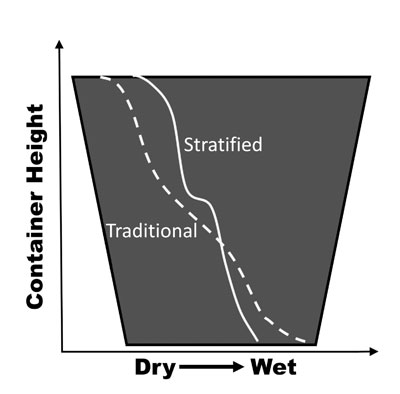

Figure 1. Computer conceptualization of the substrate moisture profile between a traditional, uniformly filled container and a stratified system. Notice how the variation between the top and bottom of the stratified substrate system is more uniform with less variation.

A stratified substrate system may involve a fine or fibrous substrate installed in the top layer or the upper 50% of the container. In this top layer, particles are engineered to hold more water and mineral nutrients by decreasing the pore sizes, which results in slower water movement and more even wetting fronts as water moves down the container profile. In a standard container, water and mineral nutrients are usually lost quickly in the top of the container due to gravity pulling water downward, wasting costly resources. This downward pull of moisture results in a wet container base, as water is retained (sometimes known as a perched water table) despite drain holes present. This decreases air availability for respiring roots.

With the additional moisture retention in the upper container, we must incorporate coarse materials in the lower half, thereby improving drainage and increasing air-filled pores. Ensuring that water and mineral nutrients are retained in the upper half, while improving air-filled porosity in the lower half, we’re thus defying gravity.

While a typical container substrate will have what’s known as a standard moisture gradient (drier on the top and wetter on the bottom; see Figure 1), a stratified substrate is designed to maintain balanced moisture throughout the container profile. We believe this balanced moisture throughout enables stratified-grown crops to utilize their resources more efficiently than traditionally grown crops.

To expand, this enhanced water and mineral nutrient retention can allow growers to improve their irrigation and fertilizer efficiency because less water is pulled downward instead of being retained in the upper sections where initial plant demand is higher. In establishing crops, the greatest proportion of roots are exploring the upper sections of the substrate profile. In view of this, stratified substrates hold water that’s more available to the crop because it doesn’t leach from the depletion zone as quickly, enabling roots to take up the water more easily and expend less energy. Plus, roots respiration is critical to crop health and development. The increased air-filled porosity in the lower half supports improved root respiration.

Stratified substrate study

A new breakthrough in stratified substrate research was recently published that indicated the success at reducing peat requirements for growers. In this research, we evaluated the potential of stratifying high-performance greenhouse substrates (i.e., peat-based) atop low-cost pine bark to reduce peat inputs by upwards of 50%. All of the plants grew with great and saleable quality, and the stratified-grown crops had much greater rooting. It appears that the roots stayed and explored the upper layer longer in a stratified system until resources were exploited, then grew downward into the lower layer. Thereafter, root growth in the lower bark layer was significantly greater than the top, highlighting the importance of the increased air-filled porosity.

The roots of traditionally grown plants immediately grew towards the container base, yet root growth in the bottom layer was significantly less than stratified-grown roots. Enhanced root growth in stratified-grown crops may indicate better transplant success post-container (see Figure 2). More research on root growth and productivity, as well as transplanting stratified-grown crops, is to come.

Figure 2. Root growth of petunia crop grown in a traditional peat-based substrate and a stratified substrate system with the traditional peat-based substrate layered atop aged pine bark. The stratified system promotes enhanced root growth through more optimally balanced air and moisture, while providing adequate nutrients for crop growth.

Figure 2. Root growth of petunia crop grown in a traditional peat-based substrate and a stratified substrate system with the traditional peat-based substrate layered atop aged pine bark. The stratified system promotes enhanced root growth through more optimally balanced air and moisture, while providing adequate nutrients for crop growth.

Stratifying peat substrates presents several more opportunities in crop production to continue reducing their peat inputs and practice alternative substrate management techniques. For starters, each layer is initially evaluated at 50% of the vertical container volume. However, current research is evaluating the layering depth ratio to reduce peat reliance even more than 50%. Going in the other direction, growers who are interested in stratification, but might feel hesitant to cut back 50% of their high-performance substrate application, can gradually incorporate stratified management practices by only stratifying the lower 25% (e.g., 75% standard substrate in the top strata layered over 25% bark in the lower strata). As we continue to experience growing substrate demand and competition, further research may indicate the flexibility in stratified substrate systems by determining if other low-cost substrates components can be utilized in the bottom layer.

In all, stratified substrate research is a relatively new concept that offers numerous opportunities to improve horticultural production, sustainability, and most importantly, cost. The added advantages to producing similar-quality or better-quality crops, while simultaneously reducing water and fertilizer input applications, is beneficial for growers with regards to cost expenditures/savings, and for environmental sustainability by reducing finite resource use. As technological advances become more apparent in the industry, there are automation opportunities to streamline container filling, especially for stratified substrate management systems. As stratified substrate research continues, we expect to present even greater benefits in time. GT

Jeb S. Fields is an Assistant Professor & Extension Specialist with Louisiana State University Agricultural Center. He serves as director of the Hammond Trial Gardens and Assistant Research Coordinator of the Hammond Research Station, and is the editor of the Nursery & Landscape Insider newsletter. Kristopher Criscione is a Ph.D. student in the LSU Fields Lab studying substrate-root dynamics.

If you’re a grower interested in evaluating stratified substrates, the Fields Lab at the LSU AgCenter would love to hear from you and assist in any way that we can. You can contact Dr. Jeb Fields at JFields@agcenter.lsu.edu. We would also like to thank the Fred C. Gloeckner Foundation and Mr. Tony Carter of Langridge Plant Sales, Inc. in Belle Chasse, Louisiana, for their support and insight into this work.