2/1/2023

Trends in Biocontrols

Julie Martens Forney

Using biocontrol agents in ornamental crop production isn’t new. Back in the 1990s, this magazine reported on IPM programs using

Encarsia formosa for whitefly control and beneficial fungi like Trichoderma for root rot pathogens. More recently, the American Floral Endowment (AFE) funded work on using cutting dips for pest and disease control on unrooted cuttings, a practice that shows how biocontrol agents can be used successfully in IPM.

The interest among U.S. growers in biocontrols is expanding and continuing to grow, according to Dr. Michael Brownbridge, Biological Program Manager for BioWorks.

“A few years back, the attitude was, ‘I’ve exhausted all chemical options, so I’ll try biocontrols.’ Now growers realize that the best pest and pathogen control systems are ones that use a holistic approach,” he said.

The Canadian greenhouse industry has adopted biocontrols faster than U.S. growers due to restricted access to chemicals. In fact, in Canada, it’s “basically normal to use biocontrols,” said Dr. Rose Buitenhuis, Senior Research Scientist in biocontrols from Vineland Innovation & Research Centre in Ontario. “We’re reaching a saturation point where all growers who can use biocontrols are. Our latest survey shows 94% of growers using biological controls for pest control.”

Pictured: Canadian greenhouse growers (42%) report thrips as the most common pest causing crop losses. Species include (left to right): Western flower thrips, onion thrips and chrysanthemum thrips.

Pictured: Canadian greenhouse growers (42%) report thrips as the most common pest causing crop losses. Species include (left to right): Western flower thrips, onion thrips and chrysanthemum thrips.

Suzanne Wainwright-Evans runs Buglady Consulting, offering pest management advice that specializes in biological control. She’s been working with growers and developing effective biocontrol programs for over 25 years. She sees growers most eager to try biocontrols are in areas where “there’s a strong extension program that pushes education. Otherwise, people are hesitant.”

Which is a shame because biocontrols are “becoming necessary,” said Dr. Jim Faust, Clemson University. He’s been studying biological control options for Botrytis, research that’s fully funded by the Endowment.

“Chemical products aren’t working as well as they used to because of resistance in bugs or pathogens. New chemical products aren’t being introduced at a fast pace, so alternative strategies are the answer,” he said.

Drivers behind biocontrol use

Resistance and lack of effective chemistry top the list of why biologicals are gaining a following among growers. The resistance situation is particularly alarming and fuels Jim’s work with Botrytis.

“It’s really an international problem,” he said. “We’ve imported cut flower roses from six different countries around the world and tested them for six different classes of fungicides. Two classes of fungicides are universally ineffective and some Botrytis spores are resistant to all six classes of fungicides. They don’t respond to anything we apply.”

Where biocontrols fit is providing a way to interrupt fungicide applications. “If a grower can use something besides a fungicide 40% to 50% of the time, this really reduces conventional applications so that when fungicides are applied, they’re more likely to be effective,” Jim explained.

The same issue with resistance exists among pest populations. “In Canada, we have fewer chemical products here because our market is smaller, so when we did get a new chemical, the thrips we imported on plant material were already resistant,” Rose said.

“If history has shown us anything, it’s that continuing to use the same product against the same target leads to resistance. Western flower thrips, two-spotted spider mites, whiteflies, aphids—they all reproduce really quickly and rapidly develop resistance,” Michael added.

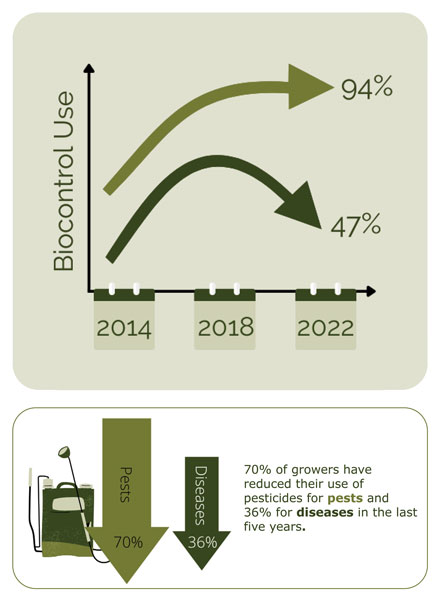

Pictured: Biocontrol adoption for pests by Canadian ornamental growers is high—near a saturation point at 94%, according to Dr. Rose Buitenhuis. Most growers using biocontrols do so 50% of the time or more in their pest control programs. The lower line (47%) represents biocontrol adoption for diseases.

Pictured: Biocontrol adoption for pests by Canadian ornamental growers is high—near a saturation point at 94%, according to Dr. Rose Buitenhuis. Most growers using biocontrols do so 50% of the time or more in their pest control programs. The lower line (47%) represents biocontrol adoption for diseases.

The Vineland Research & Innovation Centre did a grower survey to provide a snapshot of biocontrol use and pest and disease challenges. Using biocontrol methods has resulted in reduced pesticide use over the last five years.

Worker safety is another reason that growers are interested in using biological controls. With EPA-registered spray biopesticides, the re-entry interval might be four hours, compared to an eight-, 12- or 24-hour REI with synthetic chemistry. Macrobiologicals like mites or insects have no REI.

“The better you make the work environment, the more likely you are to attract better workers and retain them,” Michael said.

Misconceptions about biocontrols

Suzanne quickly listed the most common myths about biocontrols.

“That you can’t spray pesticides when using beneficial insects, it’s more expensive and that consumers won’t like the final plant because they’ll see bugs on them. None of this is true,” she said.

With biocontrols, it’s not an either/or approach when it comes to using chemicals, but a both/and. A combination of biology and chemistry delivers great success. For instance, “you can use biologicals up front to keep pest issues in check all through a crop if the weather is just right,” Michael explained. “That lets you save chemistry until the last few weeks of production so you can clean things up prior to shipping.”

The flip side is true, too. “If you have high pest and disease pressures, you can use chemistry first like a battering ram to knock down the problems and follow up with biologicals to mop up and provide protection to the plant,” he continued.

When it comes to diseases, he pointed out “there’s an increasing body of scientific evidence that if you use a combination of biology and chemistry you get better disease control.”

Suzanne works to develop customized solutions for growers. “We use a combination of predatory mites, beneficial insects, predatory nematodes and microbials, along with conventional chemistries. It’s the truest definition of IPM possible—it’s a mash-up of everything,” she said. “It’s economical and it works.”

As for objections that biocontrols cost too much, Rose points out with their Canadian grower surveys, the cost factor quickly disappears when growers master an effective program.

“We did the first survey in 2014 and cost was one of the top reasons growers didn’t use biocontrols. But 10 years later, cost is at the bottom of the list,” she said.

“If you do a product-to-product comparison—the bottle of chemical and the package of biocontrols—maybe the biocontrol doesn’t look as favorable. But once it works, it works well,” she added.

Compared to five years ago, the Canadian surveys have found that roughly 70% of growers reduced pesticide use and expenses, and increased their use of biologicals.

Michael points out that it’s best to consider the first year of using biocontrols as an investment. “That’s the time you’re learning, so you might be quite conservative or overapplying. Over time, the majority of practitioners say it’s not cheaper, but it’s not more expensive, either. It’s very cost comparative, especially with the new synthetics,” he said.

In terms of specific pests, “a two-spotted spider mite biocontrol program is generally less expensive and less wear-and-tear on growers,” Suzanne explained. “You apply the predatory mites every two weeks, (as) opposed to donning a suit and spraying every couple of days. Mealybug biocontrol is typically more expensive, but prices have come down on many biocontrols through the years.”

She also stressed trying to find someone who can address your specific problems in your growing environment. “You can call a biocontrol company and they may give you a bread-and-butter program for poinsettias, for instance, but you need to make sure that is right for your facility. Every biocontrol program needs tweaking to make it specific to a facility’s growing environment.”

The bottom line is that cost isn’t a simple equation.

“What is the cost of a pest developing resistance? What does having a safe environment mean to you? If someone is spraying at the end of the day, earning overtime, having the right licenses, personal PPE and spray equipment—are you including all of those costs for synthetics?” Michael added. “The main thing is to invest in something you know works.”

Keys to success with biocontrols

Start small. Start on half an acre, then an acre, then grow to 10 acres. “With experience comes confidence, with confidence comes the ability to add more components into the system,” Michael said. “Gateway solutions, like predatory mites or nematodes to control soil-dwelling phases of pests, are easy to use and effective.”

Don’t quit. “In the first two years most growers want to give up,” Rose said. “They want the easy option of going back to chemical control. It’s so tempting—it’s their livelihood. But once they’re over the hump of figuring out what works and what doesn’t, they don’t want to go back.”

Tap into resources. Find expertise you can trust, such as your local extension agent or a biocontrol consultant or company. Attend grower meetings (regional ones may be more focused on local pest issues) and read articles. “Find someone who really knows what they’re talking about,” Suzanne said. “You need someone you can call if a mealybug issue pops up during your biocontrol program for whiteflies.”

Adapt readily. Biocontrol programs are “forever changing,” Suzanne said. “We’re constantly finding new tools and new ways to do things, along with new invasive pests. Just because a program works one year doesn’t mean it will the next year.”

Identify pests. “We’re so used to dealing with Western flower thrips, but we’ve had some growers dealing with other species,” Rose said. “They applied their WFT strategy and it didn’t work. Then it’s back to spraying, which only works a few times and then kills the rest of your biocontrol program.” Vineland Innovation & Research Centre and the Ontario Ministry of Agriculture, Food & Rural Affairs have developed an easy-to-use thrips identification key, which would be applicable to Northern U.S. growers, too.

Think creatively. Success with biocontrols hinges on seeing the big picture. “When I go into a facility, I think about the direction the wind is flowing, what’s the crop next door, what’s the workflow—I look at all these things when creating programs,” Suzanne said. “Biocontrols is a more holistic approach.”

Don’t cut corners. Beware of black market biopesticide products, many of which are sold online. “It’s important to use EPA-registered products or minimum-risk pesticides that have been well vetted,” Suzanne said. “These black-market products often aren’t what they say they are, don’t have much active ingredient and could have human pathogens in them.”

Maximize conditions. Understand the relationship between growing environment and disease development. “With Botrytis, if we can keep it dry enough in the greenhouse, we can control disease,” Jim said. “Make fungicides your second choice after controlling the environment.”

What’s next with biocontrols?

“Biocontrols are tangible and it’s a natural system,” Suzanne said. She hopes to see more funding directed toward finding native beneficial insects and mites.

“They did this in Canada and found brown lacewings, a predatory mite and a native predatory fly—and developed systems around them. In agriculture, they’ve found that the naturally occurring predatory mite Phytoseiulus persimilis has a higher pesticide tolerance than commercially reared ones. Native beneficials are developing resistance, too,” she said.

Rose hopes to see more research in biocontrols for disease pathogens, like the work Jim is doing. “We have a Pseudomonas that has worked against Botrytis in some of our studies and we’re experimenting with some very conventional food preservatives, like the ones that prevent mold (fungal) growth in cheese or bread,” he said.

His work also is focused on trying to understand how to signal plants to fight against disease. “If we can figure out how to turn on some of those natural processes, we can apply products that stimulate plants to use those resources,” he said. In terms of conventional chemical fungicides, he sees that “there’s an endgame there. Society will eventually be intolerant of the products, so we have to come up with a different strategy.”

Rose said she believes “pesticides will always be part of an IPM strategy, but not the first thing a grower reaches for. I think they’ll be used more as a course correction or backup or at the end of a crop as a clean-up tool. Pesticides have their time and place—and we want to keep the products that work and keep them working.” GT

Julie Martens Forney is a freelance writer with more than 25 years of experience writing about floriculture industry issues and gardening for consumers. To read her current bylines, check out ASCFG’s Cut Flower Quarterly, SAF’s Floral Management and HGTV.com.

You can find the results of all AFE-funded research free on the website (endowment.org). Or plug into free monthly Grow-Pro Webinars that present the latest information available to fine-tune your crop production skills. Webinars include live Q&A sessions. For a full list of upcoming webinars, visit endowment.org/webinars.

AFE is dedicated to the floral industry. If you want to partner with AFE, you can contribute with a donation (tax deductible) or an idea for a research project. Learn more by visiting endowment.org or reach out to Dr. Terril Nell, AFE’s Research Director (tnell@afeendowment.org).