10/1/2022

Do These Things Now

Christopher J. Currey

We talk about “efficiency” in production quite a bit, much like “sustainability.” But what does is actually mean? Efficient is defined as “maximizing productivity with minimum wasted effort or expense.” Ultimately, an efficient approach to producing greenhouse crops saves money and boosts the bottom line.

This article is going to focus on some of the fundamental approaches to reducing inputs in the growing environment and plant culture. These are techniques that can be implemented immediately in almost any greenhouse to reduce inputs while maintaining or increasing

productivity.

Pictured: While growing cooler may seem to be a good way to save on costs, sometimes it can increase them. The New Guinea impatiens here were grown too cool, as indicated by the leaf purpling and the slow development of flower buds. Growing warmer can actually reduce overall crop time, as well as the energy bill.

Efficient scheduling

One of the first things, if not the very first thing, to do to increase efficiency is to create schedules for your crops. It’s surprising how many growers “shoot (or grow, rather) from the hip” with respect to crop scheduling and timing. What this usually results in is extra bench time and, along with that, the time and resources caring for those plants they wouldn’t otherwise need. Efficient production starts with efficient scheduling.

Pictured: Looking at these two crops of petunias, clearly something is different. The difference is simply scheduling. By putting together crop schedules before planting, you can avoid holding crops longer than they need to be and minimize the need for extra bench space, labor and inputs that goes along with holding.

Efficient energy use

When you think about the air temperature in greenhouses, and how to manage it to be more efficient, the first thought is to grow cooler. After all, a cooler greenhouse takes less energy than a warmer one and that saves energy, right? Well, not exactly.

Although our intuition may tell us to grow cooler to save on heating costs, this approach may end up consuming more energy (and space and labor) in the long run. Plants have different temperature requirements and we can usually group them into cool-, moderate- or warm-growing based on their response to temperature.

For those plants with cold-tolerance, growing cool can be a great approach. However, as the heating requirements increase for moderate- and warm-growing plants, growing cool will slow down crop growth and development, and increase the total time needed to reach a marketable size and appearance. This increase in bench time can cause the total energy required to produce that crop at cooler temperatures to be greater than if they were grown at a warmer temperature for a shorter time period. By growing plants at their appropriate temperatures, you can minimize the total time needed to produce flowering crops.

Efficient lighting

Like temperature, light also can be used to produce crops more efficiently. Specifically, managing the photoperiod and daily light integral (DLI) can help minimize production times. When flowers have a photoperiodic flowering requirement, such as short- or long-day responses, providing inductive photoperiods helps induce flowering on time. Although growing flowering crops under non-inductive daylengths is useful or even required to bulk up plants in their container, continuing to grow them under non-inductive conditions just increases their production time and increases the labor, water, fertilizers and plant growth regulators (PGRs) that are needed.

In addition to the duration of light during the day, the cumulative amount of photosynthetic light during a day, or DLI, can also shorten crop times. For instance, increasing the DLI with supplemental lighting during rooting for vegetative cuttings can shave up to a week or more off propagation times. Like growing at warmer temperatures, it may seem counter-intuitive that using supplemental light—an additional input—can improve efficiency. But the reduced bench time can be used in an efficient manner. For instance, perhaps you can delay opening an additional bay for production with the shorter crop time, or if you’re able to shave time off of multiple crops you’ll be able to add one additional turn in the same space.

Efficient watering

When it comes to irrigating greenhouse crops, one of the most essential skills any grower can learn is to grow dry. Of course what “dry” means is relative and will vary among crops—what may be “dry” for New Guinea impatiens is going to be different than what it would mean for lantana. But, setting the differences among plant species aside, reducing the amount of water provided to plants can have a large impact on the amount of water needed to produce marketable crops.

Pictured: While these petunia plants look great and are proportional to the containers they’re growing in, there’s one main problem—not a flower in sight. If a long-day photoperiod could have been provided using day-extension or night-interruption lighting, these plants would be in flower and completely marketable at this stage. Providing inductive photoperiods to promote flowering is essential to minimize production time.

Pictured: While these petunia plants look great and are proportional to the containers they’re growing in, there’s one main problem—not a flower in sight. If a long-day photoperiod could have been provided using day-extension or night-interruption lighting, these plants would be in flower and completely marketable at this stage. Providing inductive photoperiods to promote flowering is essential to minimize production time.

There are some benefits to growing dry, such as minimizing root-zone pathogens and, for some species, excessive growth may be inhibited. Regardless of these benefits, reducing the amount of water used to produce plants conserves water. This saves water resources regardless of the source, be it a municipal water system, surface water sources (i.e., pond) or a well. Growing dry is more challenging than it seems and a careful eye needs to catch plants before any damage occurs from wilting or excessive drying down. The use of sensor-based automated irrigation systems is the best way to grow on the drier side—plus, the automated system will also save labor.

Efficient nutrition

We fertilize crops to make sure they appear healthy and marketable, however, it’s fairly common for us to over-fertilize crops out of an abundance of caution to make sure they look good. Many containerized greenhouse crops can be grown with less fertilizer than is recommended. For instance, it’s not uncommon to see rates ranging from 200 to 300 ppm nitrogen (N) for many vegetatively propagated spring bedding plants. This will certainly result in healthy-looking plants, but it also will increase the amount of fertilizer running out of the pots and down your drains. It may also require more growth-retarding chemicals to manage plant size.

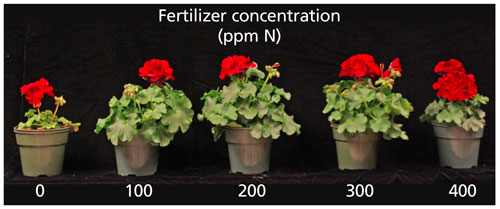

Pictured: It’s common to see fertilizer recommendations of 200 to 300 ppm nitrogen when growing vegetatively propagated zonal geraniums, but is it needed? Providing 100 ppm nitrogen resulted in a healthy and marketable crop. Reducing fertilizer concentrations—especially nitrogen and phosphorous—can still produce healthy plants, and minimize excessive growth and unwanted fertilizer leaching and runoff.

Start reducing the amount of fertilizer applied to plants. The range of floriculture crops that can be finished with fertilizer concentrations between 100 to 150 ppm N is wide—from annual and perennial bedding plants to potted crops like mums and poinsettias. In fact, many bedding plants can be grown at even lower fertilizer concentrations (50 to 75 ppm N). Reducing fertilizer applications can tame excessive growth and reduce fertilizer losses from leaching and non-point irrigation.

When lowering fertilizer concentrations, use a fertilizer with a higher micronutrient package as the peat-light and boosted base formulations. Since all nutrients are tied to your N concentration, this will help avoid any micronutrient deficiencies that could occur.

Efficient PGRs

Plant growth regulators can’t make a bad grower good, but they can make a good grower great. Using PGRs doesn’t only offer opportunities to improve plant quality, they also can make crops more efficient with respect to space, cultural inputs and labor. Using anti-gibberellin (GA) PGRs helps produce plants that are proportional to the containers they’re grown in. But these more compact plants aren’t just aesthetically balanced, they’re also more space-efficient and can be grown in closer spacings, increasing the number of containers per unit area in the greenhouse. In addition to taking up less space, the smaller plants require less water and less fertilizer as compared to larger plants, saving additional inputs and resources.

Pictured: Instead of picking off the lower, yellow leaves and premature flowers by hand, plant growth regulators can be used to reduce leaf senescence and premature flowering … and labor, too.

Increasing efficiency is not only for PGRs—other PGRs, such as sprayable auxin (Advocate, Hortus IBA salts), ethephon (Collate, Florel), benzyladenine (BA; Configure) and BA+GA4+7 (Fresco, Fascination) can also be used to improve crop growth and quality while saving labor. Newer formulations of auxin can be applied as a foliar spray after cuttings have been stuck, reducing the need to dip cuttings. Or instead of removing yellowing leaves or flowers by hand on geraniums, BA+GA4+7 applied at the beginning of propagation can reduce lower-leaf yellowing, while ethephon sprayed once rooted cuttings are transplanted can inhibit flowers from developing prematurely. Pinching is used for many spring annuals to improve their appearance; growers can use BA to promote branching in lieu of labor-intensive pinching or shearing. While there are input and labor costs associated with using PGRs, they’re more than offset by the benefits they provide.

These strategies are sure to reduce labor and resource inputs into production, while maintaining and in some cases, increasing the number of plants we can grow. But these strategies also do more than increase the efficiency of crop production. In many of the instances, they also increase the quality of the finished plant material. Reduce inputs and improve quality? That sounds very efficient to me. GT

Christopher J. Currey (ccurrey@iastate.edu) is an Associate Professor in the Department of Horticulture at Iowa State University.