6/1/2022

The Benefits of Finned Pipes

Jim Rearden

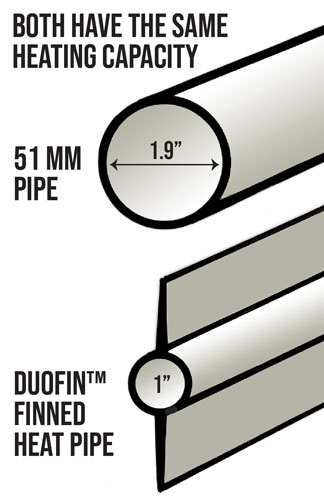

Low-mass, low-water volume heating systems are essential for today’s precisely controlled greenhouses. Aluminum finned heat pipes are systems with high reaction/response to greenhouse temperature changes. Since only a small amount of water needs to be heated, setpoints are easily maintained and the temperature lead/lag associated with high mass systems is eliminated. Compared to standard hot water pipe systems, like 51 mm “Dutch pipes,” these systems can have as much as 80% less water volume, which means quick startups and less temperature overshoot, and much better energy efficiency.

Pictured: StealthFin was created specifically for growers who want to provide a balance of top and bottom heat.

Pictured: StealthFin was created specifically for growers who want to provide a balance of top and bottom heat.

Constructed of super-conductive aluminum alloy, these products provide low-mass, high-output heating for under-bench, under-gutter, cut flower and perimeter heating applications.

In addition to aluminum’s excellent heat transfer capabilities, it holds up to the harsh elements of the greenhouse environment. These pipes withstand all commonly used fertilizers and typical greenhouse chemicals. They won’t rust or corrode. Also, a side benefit of lower water volume is that you need substantially less water treatment than with conventional systems.

The benefits of aluminum finned heat pipe heating systems are:

• Quick installation without special tools or skills

• Low water volume and high heat transfer for quick response

• No maintenance exterior—no painting, ever

Pictured: DuoFin’s unique tapered fin design delivers a combination of convective and radiant heating quietly and efficiently.

Pictured: DuoFin’s unique tapered fin design delivers a combination of convective and radiant heating quietly and efficiently.

BioTherm offers three varieties of aluminum finned heating systems:

• DuoFin provides incredibly even heating across the width of your growing areas. Its unique tapered fin design delivers a combination of convective and radiant heating quietly and efficiently. Having only two fins means that more loops are needed to meet your heat load than with sister product StarFin. But it also means you never have to clean debris from the fins.

• StarFin’s tapered six-fin design has 2.5 times the surface area of two-fin designs or 51 mm thin-wall steel tubing. This increased surface area produces StarFin’s high heat output, allowing lower water temperatures to be used and produces a soft, gentle heat. High heat output cuts installation time and labor because fewer pipes are required to meet the heat load. Also, less pipes mean less light-stopping shadowing in overhead applications. Also, our large I.D. allows long loops with generous flow rates, resulting in greater heating evenness.

• StealthFin is a unique development and has been created specifically for growers that desire to provide a balance of top and bottom heat delivery. Many growers find that, while heating from the bottom increases growth, adding a bit of directed energy above the crop can reduce Botrytis-causing moisture and can help produce a hardier rooted cutting or mature plant.

StealthFin’s design cascades radiant heating energy down on the tops of the plants. It’s usually installed 2 to 3 ft. above the crop as an augmentation to DuoFin or StarFin located beneath the crop. StealthFin is supported by a longitudinal rib integrated down the length of the pipe. Simply punch or drill a hole at the hanging point and insert support chain or wire hook every 12 ft. or so.

StealthFin’s design cascades radiant heating energy down on the tops of the plants. It’s usually installed 2 to 3 ft. above the crop as an augmentation to DuoFin or StarFin located beneath the crop. StealthFin is supported by a longitudinal rib integrated down the length of the pipe. Simply punch or drill a hole at the hanging point and insert support chain or wire hook every 12 ft. or so.

Why have a pipe with fins on it in the first place?

Finned elements are common in all kinds of applications. Electronic devices have finned “heat-sinks,” car radiators have finned surfaces—just look around and you’ll see these everywhere. Essentially, putting a metal fin on a pipe provides more surface area for heat transfer and extracts more available energy from the circulating fluid, which in this case is water.

Round pipes without fins are limited to their own surface area for heat transfer, therefore, they need to get bigger around to deliver more heat. The problem is that with every incremental increase in pipe I.D., there’s a quantum increase in water volume and mass. The correlation between how much water volume is truly needed for heat transfer and what can be contained in a round pipe aren’t balanced.

• Water volume: StarFin has only 35.4% of the water volume of 51 mm steel, while the heat transfer capacity is 2.5 times that amount. This is because the maximized

• The weight (including water) of a 1-ft. StarFin is 1.225 lbs. compared to that of 51 mm, which is 3.048 lbs. However, since you only need 1 ft. of StarFin for every 2.5 ft. of 51 mm, the effective difference is that StarFin system weighs 1/5 of the 51 mm system! In 1 acre of greenhouse, an overhead 51 mm system could weigh 47,792 lbs. compared to a StarFin system at only 9,604 lbs. Think about that next time it snows.

Tapered fin design

Our fins are designed with a thick base and tapers toward the tip. Common sense tells you that having more “base” to gather the heating energy from the water flow gives more fin efficiency. Our studies reveal that this is indeed true. Heat transfer from our fins is consistent from base to tip.

The benefits of aluminum finned pipe systems over steel piping

Aluminum transfers heat three times faster than steel. It heats up and cools down faster, meaning your heating system is much more responsive. Additionally, it doesn’t rust and gives the advantage of a no-maintenance surface in the greenhouse environment. Heating systems made of steel pipes need to be protected from corrosion by painting them from time to time. Painting pipes under greenhouse benches isn’t pleasant work. Aluminum finned heat pipe eliminates this altogether.

Pictured: The increased surface area of the StarFin provides high heat output, allowing for lower water temperatures to be used, producing a soft, gentle heat.

How low mass and low water volume translates to energy savings

When your thermostat or control system asks your heating system to start, the request can be acted upon much more quickly if the system has 83% less water and only 20% of the mass. This means that minimum pipe temperatures can be achieved much quicker, the entire response is much more rapid and you don’t have to start your boilers early to anticipate the coming loads.

Moreover, at the end of a heating cycle, less energy is left in the system when the heating load stops. These two effects and have a very large cumulative impact on your energy costs.

When we went to using BioTherm’s Finned Pipe heating under the crop instead of our old steel heating system, we had exact heat placement across all locations. Overall, the heat uniformity across the bench surface was amazing, and it really changed us and allowed us to ultimately control the crop we put in each zone.

We have both under-bench and top-bench heat. There’s enough heating BTU potential in each system to run each zone independently. If we needed to have a warmer root zone to push the plants, but have a cooler canopy, we use it as a toning tool to keep plants more compact by not having as much top heat. We also use it as a stretching tool to give plants more vigor.

Being in Northeast Iowa, we have frigid winters. BioTherm’s heating systems have been a staple and a big piece to us being able to produce plants year-round. They keep us warm, and if we didn’t have them, we’d be in a really tough spot.

Watch the YouTube video.

—Mike Gooder, John Gooder and Jason Sbiral, Plantpeddler, Cresco, Iowa

Progressive Improvement of BioTherm’s Finned Heat Pipes

BioTherm’s engineers are tasked with constantly improving all the company’s products. They recently reviewed their tooling for their heat pipe products and realized that with a minor modification of adding small ridges to the surfaces, they could increase the performance by 6.7% to 10.5% with only minor additional use of aluminum.

“It’s like we added micro-fins to the main fins,” said Jim Rearden. “We will be enhancing all of our heat pipe tooling to include these enhancements.” GT

Jim Rearden is president of BioTherm. BioTherm has over 40 years of experience providing cultivation climate technologies to growers all over the globe. We have been at the forefront of developing cutting-edge products to help growers grow better-quality plants while saving money and increasing production time. To learn more, visit www.biothermsolutions.com or call (800) GET-HEAT.