11/1/2019

Wood Substrates: Supplies, Sources & Sustainability

Dr. Brian E. Jackson

With the use of wood substrates and substrate components on the rise, one of the many questions often asked by growers and the general public is about the sustainability of using wood and the long-term impacts and supply of one of our most valuable (economic and environmentally) natural resources.

Figure 1. Loblolly pine forests cover almost 30 million acres in the southern U.S. A) Harvested trees are de-limbed; B) debarked or not and processed in shredders; C) or chippers; D) yielding the feedstocks used to make wood substrates.

To provide some perspective on these questions, let’s first look holistically at the forest lands/resources in our vast country. As of 2016, approximately 36% of the U.S. (not including territories) is considered forested land. This landmass covers roughly 818 million acres from coast to coast. Even though the U.S. is the fourth largest forested country (behind Russia, Canada and Brazil), it’s the most industrially productive forest area in the world. The most productive region is our Southern forests, known as the “Wood Basket of the World,” which represent only 2% of the global forest cover, but the area provides 12% of the world’s round-wood, and 19% of its pulp and paper!

While there are dozens of economically important tree species in our forests, none compare to the value and dependency that we have for loblolly pine (Pinus taeda). According to the U.S. Forest service, there are currently about 30 million acres of planted/managed loblolly pine in the U.S., which makes up one half of all standing pine volume. There are a projected 750,000 acres (300,000 hectares) of loblolly harvested each year in the U.S.

The lowdown on loblolly

Above all others, loblolly is the king of the forest. Loblolly translates to “mudhole,” which indicates its native growth habitat in lowland areas, even though it will also grow in higher and drier sites (but not generate optimal growth, as it does love water and nutrition). Loblolly is found naturally in 14 states in the South (Zones 6 to 9), ranging from the New Jersey shoreline to Central Florida and west to parts of Texas and Oklahoma.

Figure 2. The edges (side planks) are removed from sawlogs at the mill. The inside “heartwood” of the tree (shaded portion) is used for lumber, poles, etc. while the removed outside “sapwood” edges can be chipped and used as feedstocks for making substrates.

Recent U.S. Forest Service surveys discovered that loblolly is the second most common native tree in the entire country after the red maple (Acer rubrum). Other common names for loblolly include “old field pine” and “southern yellow pine.” Southern yellow pine is often used universally across many native species of southern pine, which can be very confusing when communicating with others in different states, geographic regions, industries, etc.

As it relates to wood fiber substrate production, loblolly trees can be harvested, chipped or shredded and wood chips then further processed specifically for substrate production (using the entire log or tree; Figure 1). Some greenhouse operations in the U.S. have invested in the ability to harvest and process their own trees into substrate. Others buy wood chips (pulp chips otherwise deemed for paper) and process those in hammer mills and other systems to create their substrate materials.

Another source of pine wood proven to be successful comes from clean chip residuals (often referred to as hog-fuel), which is comprised of all parts of harvested pine trees except the logs (boles, as they’re called) themselves. Dr. Cheryl Boyer, Associate Professor at Kansas State University did her Ph.D. work on this material. In addition to those residuals, other growers and researchers have trialed pole peelings, pruning wastes, various sawdusts, etc. (Figure 3).

Another source of pine wood proven to be successful comes from clean chip residuals (often referred to as hog-fuel), which is comprised of all parts of harvested pine trees except the logs (boles, as they’re called) themselves. Dr. Cheryl Boyer, Associate Professor at Kansas State University did her Ph.D. work on this material. In addition to those residuals, other growers and researchers have trialed pole peelings, pruning wastes, various sawdusts, etc. (Figure 3).

Figure 3. Various feedstocks and wood sources have been used as substrate components or to make substrate components.

Lastly, the pine wood source for substrates may come from the planked (cut off) edges of harvested trees (Figure 2). A practice I first learned/saw in Europe over a decade ago was when the harvested trees have their outer edges cut off, leaving the center of the tree to be used for boards, poles, etc. The outside edges are then chipped and used for other purposes—in this case, as the feedstock to make substrates. I believe this to be potentially significant in that the outside edges are mostly all sapwood while the inside of the tree is heartwood.

Our wood substrate research team here at NCSU is currently investigating the effects of wood sources, tree age, type of wood (sapwood, hardwood or both), etc. on substrate properties.

Tree species

Over the past 40 years, many tree species have been evaluated for their potential to be used in soilless substrates. At last count, over two dozen have been reported in the literature. Most all works have agreed that softwood species (pine and spruce) are the better candidates compared to hardwood species. The difference in the chemical constituents of hardwoods and softwoods is the main reason for the dissimilarity. Current research is however re-evaluating ways to potentially manipulate and use hardwoods in substrates, but the work is still in progress and not yet available.

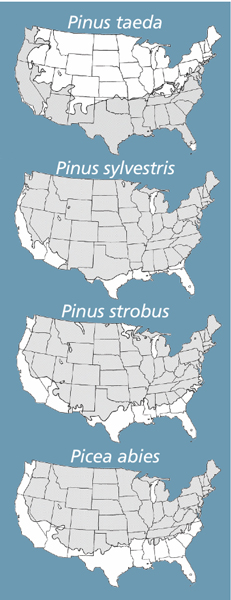

Figure 4. Shaded areas of the maps indicate potential planting range (areas where trees could possibly grow/

Figure 4. Shaded areas of the maps indicate potential planting range (areas where trees could possibly grow/

survive) of loblolly pine (Pinus taeda), eastern white pine (Pinus strobus), Scotch pine (Pinus sylvestris) and Norway spruce (Picea abies). Source: University of Florida, Environmental Horticulture, U.S. Forest Service Fact Sheets.

Many folks ask about using other pine species to make substrates, but little evidence is currently available to share. There are 36 species of native pines found across North America, but none have proven (of those actually tested) to be better than or as good as loblolly. This is fortunate considering the volume and widespread abundance of this species. Other than pine, Norway Spruce has been very successful and is used in commercial substrate production in Europe (maybe Canada soon?).

Competition for wood use

Traditional (and most common) uses of loblolly pine trees are lumber (saw timber), pulp and paper, plywood, furniture, posts, poles, pilings, and more. There are numerous other uses of pine, including a recent commercially available organic infill material used on artificial turf fields/surfaces as a replacement to crumb rubber.

One of the more potentially concerning competitors of wood resources comes from the accelerated opening of wood pellet mills in the past decade across the eastern and southern U.S. Industrial wood pellet production and use is on the rise because they’re an alternative to coal (intended to lower carbon emissions) in many European nations. At present, the threat of pine wood supplies (and prices) being negatively affected by pellet production doesn’t seem to be an issue, at least not for wood substrate production. According to recent scientific studies, despite the increased use of wood resources to make pellets, the wood used is a small proportion of currently available forest resources and thereby not a current threat.

Since wood is an extremely versatile, malleable and sustainable material, more uses will continue to be found to utilize this natural resource. In response to the current and future need of wood resources, managed pine forests are on the increase and utilization of previously unused or underused wood resources is also on the rise. Areas of the country where pines are not native could also potentially serve as viable growing areas for certain species.

The potential growth range of the top four tree species used in global substrate production (loblolly pine, eastern white pine, Scots pine and Norway spruce; Figure 4) span far outside of their native ranges, but some success in expanding tree production is being seen. Time will tell to what tangible affect. Loblolly, for example, is now being successfully grown in places across southern Europe and Brazil. It goes without saying that the future rests heavily on the production of loblolly pine for decades in the future. GT

References: U.S. Forest Resources Face and Historical Trends. U.S. Forest Service, FS-1035, August 2014. Demers, C., M. Andreu, B. McGowan, A. Long, and J. Nowak. 2019. Thinning Southern Pines—A Key to Greater Returns. Univ. of Florida/IFAS Extension,

SS FOR24.

Dr. Brian E. Jackson is an Associate Professor and Director of the Horticultural Substrates Laboratory at NC State University. He can be reached at Brian_Jackson@ncsu.edu.