3/1/2019

Today’s Tech

Chris Beytes

Today’s ultra-modern greenhouse and nursery operation wants help reducing labor, gaining efficiency and using digital tools to better manage … well, everything, from the environment to the staff. Even AI—artificial intelligence—is finding its place. But not all tools cost big euros; there are many improvements to older technologies that even the smallest of operations can afford.

That’s what we learned at this year’s IPM Essen, held in Essen, Germany, January 22-25. The world’s biggest horticulture show, IPM drew some 53,000 trade visitors from 46 nations to peruse the stands of more than 1,500 exhibitors. A small number of those exhibitors specialized in greenhouse equipment and technology, which is what we’ll focus on here.

WPS

WPS

The robot featured on the cover is from Dutch automation firm WPS, which specializes in high-tech internal transport systems for greenhouses, from planting to packing. This robot arm is a spacing robot, designed to move plants from one container to another—either moving tables or individual trays at a rate of 2,500 pots per hour.

This model showed just one gripper, but eight or more is typical. While not quite as fast as a linear mechanical system commonly used with Dutch tables, it’s more precise and more flexible, thanks to its 360-degree reach and programmability. They’re currently in operation at Dutch and Danish potted plant operations. (See a video of the robot in action at tinyurl.com/WPSspacingrobot.)

Javo

Speaking of carousel fillers, Javo has launched the Standard 2.0, a modern update of their classic Standard machine. Features include a higher capacity; rubber and stainless steel elevator; it dibbles 4,000 pots per hour (up from 3,000); has a self-adjusting carousel drive train; and an electronic speed control. It will handle pot sizes from 5.5 cm (2 in.) to 24 cm (10 in.). Cost ranges from $20,000 to $40,000 depending upon equipment. www.javousa.net

AutoStix adds roots

AutoStix adds roots

At Visser, they’ve developed a new AutoStix strip called Multi-Media, which is designed to hold a small amount of rooting medium—either loose-fill or a glue plug-type medium. This allows cutting producers to root right in the AutoStix strips, which can then be mechanically transplanted directly into finished containers. With regular AutoStix strips, the unrooted cuttings have to go through the rooting process after transplant. Currently, this technology is more for Europe and spots other than North America because the U.S. doesn’t allow the import of plants in media. Selecta, for instance, is offering the rooted strips filled with peat-based glue plugs, which they call ROCS, from Kenya into Europe.

A coming attraction from AutoStix will be the Flex, with a four-gripper head that can be positioned over conveyor belts or carousel-style pot fillers. It’s said to be ideal for smaller growers. www.bellparkhorticulture.com

Ellepot Pillow

Orchids and other plants with sprawling root systems are challenging to pot, but now Ellepot has a solution. Called an Ellepot Pillow, it resembles a large tea bag (without the string, of course). Filled with the mix of your choice, the pillow is gently folded around the plant’s roots and the whole thing is then stuck into a pot for growing on. www.ellepot.com

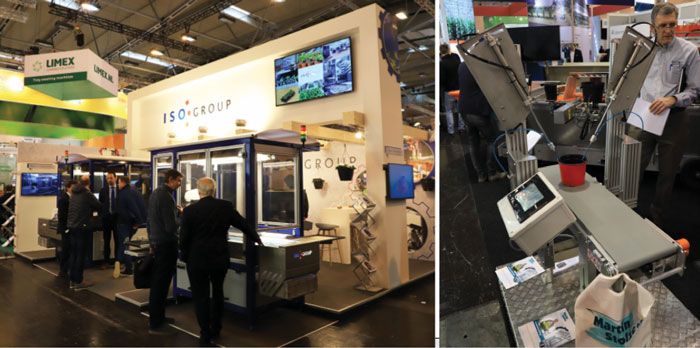

ISO Cutting Planter adds artificial intelligence

ISO Cutting Planter adds artificial intelligence

The talked-about machines right now continue to be ISO Group Cutting Planter vs. Visser’s AutoStix (we’ve featured both on the cover of GrowerTalks). ISO uses a robot to grip unrooted cuttings that have been dumped onto a conveyor; AutoStix utilizes degradable strips into which cuttings are stuck at an off-shore (Africa or Central America) location. Both systems are being used more and more widely, and both have their place. (ISO also has a combo unit, launched last year, that will stick cuttings or plant rooted plugs with the change of a head.)The big news with ISO Group is that they’re improving the accuracy of their planter by incorporating artificial intelligence—what they’ve dubbed “RoboVision AI” or RVAI. It uses “deep learning,” which means the more images of cuttings the machine takes with its two cameras, the more it learns about their shape and orientation, and the more accurately it can grab and plant them. Before this, programmers had to tell the machine all the details about stem length and leaf color. Now the machine teaches itself, getting smarter and smarter the more cuttings it sticks. www.iso-group.nl/en

Martin Stolze gel injector

“We make the brush, they make the paint” is the answer I got at the Martin Stolze stand when I inquired about this device for injecting water-holding gel into potted plants. The gel in question comes from three different manufacturers, I was told: NuGel (“Gel4Pots”), Growdesign (“Green Drops”) and Chrysal (not sure of the product). These products are so new, there’s almost no information online. (Email NuGel at info@nugel.co.uk or Growdesign at info@growdesign.nl.)

According to literature I picked up at the stand, these gel products are meant to be injected into the soil ball at shipping for extended shelf life in transport and display. I guess they work like a water-holding polymer, except in gel form, to keep the plant hydrated longer.

Lock’s Digital Limit Switch

Lock’s Digital Limit Switch

I appreciate attention to detail and nothing epitomizes that more than the inner workings of a Lock Drives mechanical gear box limit switch. Talk about a Swiss watch! (Or perhaps I should compare it to a Mercedes, since Lock is a German company.)

Regardless, now they’ve entered the digital age with a fully digital limit switch. A big benefit is easy remote monitoring and modification from your computer or smartphone. Plus, it’s extremely precise; consider how a CNC mill or lathe uses digital signals to start and stop, and you’ll get a picture of the accuracy and repeatability potential. Frank Lock says they’ve had 100 units out for extensive field testing and are now starting sales.

www.lockdrives.com/en

Pots from sunflowers

European nations are fighting plastic waste with various taxes, and companies are still struggling to find a balance between plastic recycling and true biodegradable containers. One new option is called Pott Burri from German annual and herb producer Cox Pflanzen.

Alexander Cox told me that Pott Burri is made by a German company called Golden Compounds, which has created a moldable biodegradable material from sunflower shells, a by-product of sunflower oil production. The pots are said to break down in the garden in a matter of six months or so, with no special conditions needed (unlike corn-based materials).

Golden Compounds is also making disposable coffee cups and even Nespresso-style coffee capsules (to replace the aluminum ones). Cox has

a two-year German exclusive on the technology. https://golden-compound.com/?lang=en

Low-cost options for better spraying

Low-cost options for better spraying

Dramm is promoting foam for better sanitation. Foam sticks your sanitation products to surfaces so they can do their job better. It’s used widely in livestock, but the price of the large equipment scares off many growers, says Dramm’s Kurt Becker. That’s why they created a low-cost ($130) pump-up sprayer (60 psi) that will create a nice, rich foam (not to be confused with suds, which don’t work) from your sanitizer and adjuvant. www.dramm.com

For general hand-spraying, consider one of Birchmeier’s updated backpack sprayers. There are two: Flox10 (10 liter) and Iris15 (15 liter). What’s impressive is that they’re based on the excellent Swiss engineering of the original Senior backpack sprayer, introduced in 1975. With the 2019 update, they’ve kept the external pump and long-lasting components, and added ergonomic, adjustable design features. www.itbcompany.com GT