12/1/2018

Laser Focus on Seed Quality

Allison Westbrook

Ball’s Seed’s Ball Vigor Index (BVI) has been around for more than 20 years, but it just got even better. How? One word: lasers.

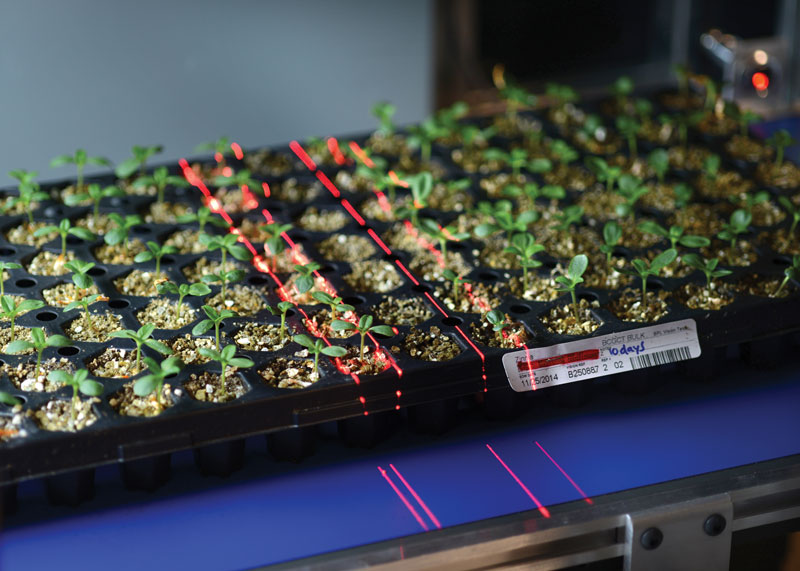

Previously, only a camera was used in the Seed View 4.1 machine, which provided a 2-D view of the plug’s size. However, it wasn’t possible to determine height, another factor that can lead to a plug being culled by a grower, as they want all seedlings to be of uniform germination rate, height and size for a plug tray to finish together. Now, with the laser technology, the tester can see a 3-D picture, showing both height and size. The BVI number can now account for those too-small seedlings that a grower would remove and provide a number that more accurately indicates how many usable seedlings a grower can expect from a seed lot.

For a bit of background, the Ball Vigor Index is a number that appears on Ball Seed packets indicating how uniform a lot of seed is. Each crop has a baseline BVI (550 to 650) and tops out at 800. The main benefit of BVI is that Ball tests seeds from all breeder producers using the same process, which allows for an “apples-to-apples” comparison of seed varieties. Otherwise, growers have to take into account that each breeder tests seeds differently and that could make a difference when comparing seed varieties.

This process, which is proprietary to Ball Seed North America, now uses the most up-to-date technology, which allows the tester to see much more detail in the results. In fact, there are actually two lasers used—the first laser shows height, and the second shows leaf area and chlorophyll action. This process takes only about 30 seconds, which allows Ball Seed to test seeds more quickly. This information also is fed back to the breeders to help them make decisions in selecting and breeding seed for uniformity.

Robert Conrad, Seed Technology Research Manager at Ball Seed, says another benefit of the laser technology is that the testing is able to be timed very early, unlike many other breeder tests.

“With a test later [in the development of the seedling], the problem is that too much emphasis is placed on the ability to grow the seedling, not on evaluation of the quality of the seed,” he explained.

With the laser technology’s ability to allow for earlier testing and more accurate results, the updated BVI process now gives an even more accurate picture to the growers of what to expect from their seed. And stay tuned—a new machine to measure liner uniformity, called Plant View, will be coming soon from Ball Seed. GT