8/1/2018

Light Learning

Roberto Lopez

One of the many reasons growers attend AmericanHort’s biennial Plug & Cutting Conference is to learn how to implement the latest cutting-edge (no pun intended) techniques and technologies that ultimately lead to energy, resource and labor efficiency, and the production of high-quality young plants. In this article, I’ll give a sneak peek into the four Michigan State University (MSU) research-based sessions I’ll be presenting at this year’s Plug & Cutting Conference.

Success with Cuttings: From Cutting Arrival to Stage 4 of Propagation (September 18, 3:15-4:30 p.m.)— Whether you’re a new or seasoned propagator, you can always improve the rooting success of those challenging vegetatively propagated annual and perennial species and cultivars. For example, do you know what caused the leaf yellowing and senescence of the geranium crop in Figure 1 and what you can do to  prevent it? Join me to get a better understanding of the ins and outs, and common mistakes made during rooting stages 0 to 4: from cutting arrival, storage and handling to callusing, rooting and toning. Learn how to better prepare for the arrival of those expensive live goods called unrooted cuttings so that you can minimize losses and even reduce rooting time.

prevent it? Join me to get a better understanding of the ins and outs, and common mistakes made during rooting stages 0 to 4: from cutting arrival, storage and handling to callusing, rooting and toning. Learn how to better prepare for the arrival of those expensive live goods called unrooted cuttings so that you can minimize losses and even reduce rooting time.

In addition, each attendee will also receive a two-page handout with a compilation of breeder, grower and academic species-specific recommendations on storage temperatures, sticking priority, rooting hormone use, dibble size, mist requirements and crop timing.

Figure 1. Yellowing around the edges of older leaves that progresses to necrosis. Caused by delayed shipping, especially if cuttings warm up over 70F (21C), storing cuttings too long or prolonged storage in a cooler.

Supplemental Lighting Defined: Guidelines, Strategies and Considerations for Young Plant Production (September 18, 10:45-11:45 a.m.)—Are you interested in potentially utilizing some sort of electric lighting during young plant production, but feel you’ve been left in the dark when it comes to the differences between supplemental, photoperiodic and sole-source lighting? To top off your confusion, academics, magazines and lighting companies use terms such as DLI, PPFD, nanometers, quantum, etc. I’ll give you examples of the various lighting applications for young plant production and cover the common definitions, guidelines and strategies used for high-intensity supplemental and sole-source lighting of young plants. I’ll also discuss key factors to consider when making a decision between greenhouse high-pressure sodium (HPS) lamps and light-emitting diode (LED) fixtures, including: lamp longevity, efficacy, cost, light spectrum, electricity rate, utility rebates and various growing scenarios.

Figure 2. Production of young plants utilizing high-intensity light-emitting diodes (LEDs) for greenhouse supplemental lighting (A) or for sole-source lighting in a warehouse (B) or low-intensity LEDs for photoperiodic lighting (boom lighting to promote flowering) in a greenhouse (C).

Energizing the Future of Young Plants: Supplemental Lighting and Root-Zone Heating (September 19, 9:30-10:30 a.m.)—Over the last decade, our research team at MSU has quantified how increasing daily light integral (DLIs; ≈1 to 15 mol.m-2.d-1) from the use of HPS lamp supplemental lighting, light quality from LEDs (red, white and blue radiation) and/or root-zone temperature (RZT; 68, 75 and 82F) influence rooting, growth, quality and subsequent flowering of the following annual and perennial genera: achillea, agastache, angelonia, argyranthemum, campanula, coreopsis, diascia, gaillardia, gaura, heuchera (coral bells; 2 cultivars), Impatiens hawkeri (New guinea impatiens; 4 cultivars), lamium, lantana, leucanthemum, nemesia, nepeta, osteospermum, perovskia, pelargonium (geranium; 2 cultivars), Pennisetum x advena (purple fountain grass), petunia (4 cultivars), phlox (garden phlox), salvia, scaevola, sutera (bacopa) and verbena. For nearly all of the 35 genera and cultivars we’ve investigated, as DLI increases from ≈1 to 12 mol.m-2.d-1, overall rooted cutting quality increases and time to produce a marketable liner decreases by one to three weeks.

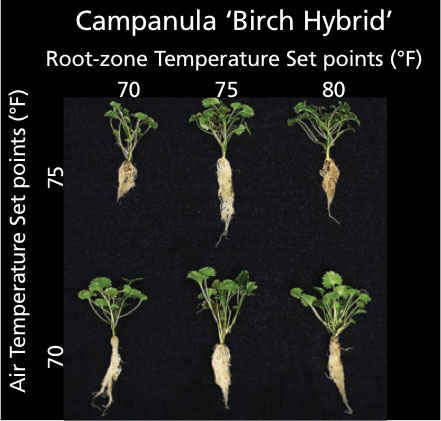

Figure 3. Campanula Birch Hybrid cuttings rooted in a greenhouse with air temperature set points of 60 and 70F and root-zone temperature set points of 70, 75 and 80F.

Figure 3. Campanula Birch Hybrid cuttings rooted in a greenhouse with air temperature set points of 60 and 70F and root-zone temperature set points of 70, 75 and 80F.

I’ll also share the result of the latest MSU research investigating the potential benefits of utilizing continuous or threshold supplemental lighting from LEDs. Since most LED fixtures can be more energy-efficient to operate than traditional HPS lamps, our next step was to determine if there was any benefit from running supplemental lighting continuously at a lower intensity, even if the sun was out.

Alternatively, we wanted to determine if it was more beneficial to run LEDs providing a low or moderate amount of blue radiation or HPS lamps at a higher intensity in the morning when it was cloudy and in the evening. Therefore, our objectives were to quantify how the spectral quality and intensity of LED supplemental lighting would influence production time of plugs and liners compared to those grown under HPS lamps.

Join me to learn about the additional benefits that can be gained from utilizing LEDs during plug production when your natural DLI is low. Discover how root-zone heating in combination with reduced air temperatures during Stage 2 to 4 of vegetative cutting propagation increases liner quality and doesn’t increase production time of cold-tolerant species (Figure 3). I’ll also provide attendees with a table that includes the recommended DLI, RZT, air temperature and vapor pressure deficit (VPD) guidelines for Stages 2 to 4.

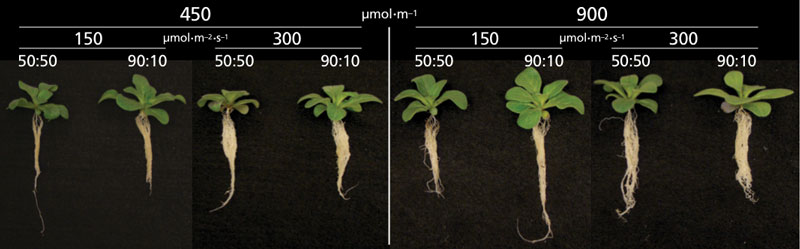

Figure 4. Petunia Dreams Midnight seedlings four weeks after germination under a carbon dioxide (CO2) concentration of either 450 or 900 ppm (µmol.mol–1) and light-emitting diode (LED) sole-source lighting with light intensities of 150 or 300 µmol.m–2.s–1 and red:blue light quality ratios (%) of 50:50 or 90:10.

Lighting the Future of Young Plants: Sole-Source Lighting (September 19, 8:00-9:00 a.m.)—Lastly, I’ll talk about the numerous benefits and potential drawbacks of growing young plants in highly-controlled indoor environments without sunlight. Plant growth and development can be substantially manipulated by the light spectrum provided by LEDs when plants are grown completely indoors, such as in growth chambers, warehouses and vertical farms. I’ll present research-based findings that show how young plants respond to different spectrums of light, light intensities and carbon dioxide levels (Figure 4).

Lighting the Future of Young Plants: Sole-Source Lighting (September 19, 8:00-9:00 a.m.)—Lastly, I’ll talk about the numerous benefits and potential drawbacks of growing young plants in highly-controlled indoor environments without sunlight. Plant growth and development can be substantially manipulated by the light spectrum provided by LEDs when plants are grown completely indoors, such as in growth chambers, warehouses and vertical farms. I’ll present research-based findings that show how young plants respond to different spectrums of light, light intensities and carbon dioxide levels (Figure 4).

I hope to see you in September at the Plug & Cutting Conference! GT

Roberto G. Lopez is Assistant Professor and Controlled Environment/Floriculture Extension Specialist in the Department of Horticulture at Michigan State University.