6/1/2018

A Taste of Water Quality

Rosa Raudales

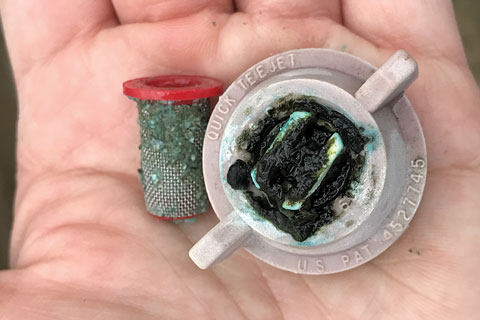

Water quality is a key factor in greenhouse production. Chemical, physical and microbial parameters affect nutrient management programs, risk of disease and efficiency of irrigation systems. In this article, I’ll discuss some examples of water-quality parameters that growers should manage to achieve high-quality crops and prevent clogging of irrigation systems. Even though I’ll present each problem separately, growers should be aware that multiple problems can occur simultaneously (Figure 1).

Chemical parameters

The pH is a measurement of the concentration of hydrogen ions (H+) in a solution. It’s an indicator of the acidity of solutions. Water pH affects the solubility of chemicals (including fertilizers in the solution and agrochemicals, like PGRs or fungicides), but has little impact on the pH of the substrate. We can measure the pH of a solution directly with a pH meter.

Alkalinity (also known as “acid buffering capacity”) is a combined measurement of all the ions in the water that are chemical bases. We can think of alkalinity as if it were “dissolved limestone” in the water. Analytical laboratories report water alkalinity in equivalents of calcium carbonate (CaCO3) in parts per million (ppm), milligrams per liter (mg/L) or milliequivalents (mEq). We shouldn’t confuse alkalinity with high pH or alkaline pH (pH >7). We cannot measure alkalinity directly with a pH meter; instead we need a specific kit to react with the solution and then measure the pH or look at the color and match it to a chart.

Figure 1. Emitter clogged on the outside with algae and on the inside filter with chemical precipitates.

Water  alkalinity has a big effect on medium pH. The effect of water alkalinity on media pH is very similar to the application and reaction of limestone. High alkalinity will increase the pH of the media and growers can inject acid to neutralize high alkalinity. (To estimate the right amount of acid, use the alkalinity calculator at http://tiny.cc/AlkCal.)

alkalinity has a big effect on medium pH. The effect of water alkalinity on media pH is very similar to the application and reaction of limestone. High alkalinity will increase the pH of the media and growers can inject acid to neutralize high alkalinity. (To estimate the right amount of acid, use the alkalinity calculator at http://tiny.cc/AlkCal.)

Fertilizers with high ammoniacal nitrogen (>20%) produce an acidic reaction in the container media, which can be used to neutralize the liming effect of water alkalinity. However, growers should use these fertilizers with caution because they may cause excessive growth, can cause phytotoxicity if used in excess—especially when the temperatures are <60F (<15C)—and tend to have lower concentration of calcium.

Low alkalinity in the water means there’s little buffer in the solution to react with acid and the medium pH tends to drop over time (peat is inherently acidic). With the right choice of fertilizers (<20% ammoniacal nitrogen) and limestone in the growing mix, growers can easily maintain optimum pH.

High concentration of specific elements in the water can also be a problem for nutrient management. Sodium, calcium, boron, iron and chloride, among others, affect cation/anion balance and influence which elements the plants will take up or can be phytotoxic to crops. We won’t cover this topic in this article, however, we’ve created WaterQual (cleanwater3.org) to help growers interpret potential problems with chemical parameters. WaterQual is a tool that interprets the quality of a water source for use in irrigation of plants in greenhouses and nurseries.

Iron and calcium precipitate

High iron (>4 ppm) in irrigation water can precipitate, accumulate and clog irrigation systems. Iron is in solution (dissolved) when the pH of the water is <6.0; as the pH increases the iron precipitates and forms what we commonly call rust. Precipitated iron clogs irrigation emitters and main pipes (Figure 2) and it stains the leaves when irrigating with overhead irrigation.

Figure 2. Iron precipitates on a main irrigation pipe.

Figure 2. Iron precipitates on a main irrigation pipe.

Iron also precipitates when it reacts with oxygen. Iron is typically a problem when using ground water (not all wells have high iron, but problems with high iron are mostly observed in wells). We estimated that a 20-acre greenhouse spent $146K annually in labor to clean and replace clogged irrigation emitters caused by iron.

Growers can do two things to manage iron-related problems: 1) avoid long-term storage of water—iron will react with the oxygen, precipitate and then accumulate through the irrigation system; and 2) have a water treatment system that includes iron oxidation (precipitation), followed by filtration. An example is to inject potassium permanganate as an oxidizer, followed by filters with glauconite greensand.

Calcium in the water reacts with bicarbonates (HCO3-) or sulfates (SO4-2) and precipitate. This will happen when both elements are at high concentrations (Ca >150 ppm and bicarbonates >180ppm). Growers are very familiar with this concept, which is why they separate stock solutions of calcium from all the other elements.

A quick fix to this problem is to inject acid to dissociate the bicarbonate ions. Growers should adjust their nutrient program when injecting acid. A more expensive solution is to use membrane filtration (e.g., reverse osmosis) to remove salts. Membrane filtration should only be used if the levels are extreme and cannot be managed with acid.

Microbes

Disease occurs when the pathogen is present, the conditions are conducive for disease to occur and the crop is susceptible. Water can play a role in both carrying the inoculum and providing optimum conditions for disease development when air or substrate humidity are high.

Irrigation water can be an inoculum or dispersal mechanism of plant pathogens. Water sourced from the ground, rain or cities doesn’t have plant pathogens (in rare cases, ground water can be contaminated from field production).

In contrast, surface water bodies (e.g., ponds, lakes) and recirculated water can have high concentration and diversity of plant pathogens. Sub-irrigation systems, regardless of the source, are at high risk of dispersing pathogens from crop to crop. This problem is exacerbated because the solution containing pathogens moves from one container or zone to another, and also because plant or peat debris on the floors or benches protects pathogens from desiccation or dehydration.

Biofilms are a combination of microbes that form a coating that protects them from desiccation and chemical treatment. In irrigation systems, when water-soluble fertilizers are used, biofilms also harbor algae. Biofilms frequently accumulate in fine emitters, filters or main irrigation pipes and clog the system (Figure 3).

Biofilms are a combination of microbes that form a coating that protects them from desiccation and chemical treatment. In irrigation systems, when water-soluble fertilizers are used, biofilms also harbor algae. Biofilms frequently accumulate in fine emitters, filters or main irrigation pipes and clog the system (Figure 3).

Figure 3a and 3b. Examples of microbial biofilm on irrigation systems.

There’s no silver bullet for control of pathogens or biofilm in irrigation. To prevent disease development, we should always think about an integrated crop management. Use resistant varieties when available, reduce the inoculum by implementing strict sanitation practices, inject low residual dose of sanitizers (Waterborne Solutions is a tool that will help you choose one) and control the environment. Biofilm is much more difficult to prevent because the cause is so diverse and the structure is so resilient.

We have some insights that might help—if you want to know more, come to the Plug & Cutting Conference in Charlotte, North Carolina. I will present more in-depth management options and additional parameters, and talk about how pipe materials and irrigation frequency affect biofilm accumulation, microbial and chemical control of pathogens in water, filtration options and PGR residues in recirculated water. GT

Rosa E. Raudales (rosa@uconn.edu) is an assistant professor at the University of Connecticut.