2/1/2018

Fine-Tune Time

Kurt Becker

Dramm was founded 76 years ago with the invention of the 400AL Waterbreaker. This tool allowed for the more even dispersion of water from a hose to the plants and soil waiting below. Today, there are dozens of watering nozzles made for hand watering.

Similarly, there are easily as many different ways to automatically water your plants. From overhead sprinklers to drip irrigation to capillary mat and other sub-irrigation methods, watering your crop has never been easier.

With any irrigation system, there are certain steps a grower can take to improve the design, optimizing it for both best watering and best management practices going forward. As a manufacturer of irrigation products, we won’t spend time on the various different nozzles and drippers that are sold in our industry. All of our industry’s manufacturers make good products, capable of automating your irrigation. This article will, instead, discuss things anyone can do to improve their systems.

Understanding flow

Too often, we’re called in to help a grower replace an existing irrigation system that they feel isn’t operating properly. Upon inspection of the system, we find that the nozzles and spacing were appropriate for their crop, but the nozzles are starving for water and not operating properly. “What’s the available flow?” is one of the first questions we ask when designing an irrigation system for a customer.

Before designing your system, consider your water source. Where’s the water coming from? Are you on city water? Is your water from a well or a pond? What’s the flow rate of these various sources?

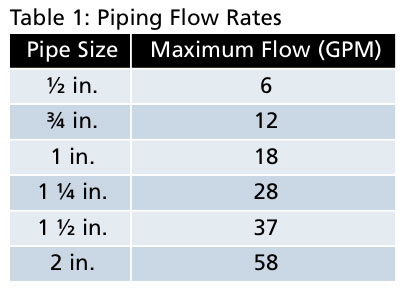

From there, what piping is used to run from your source to the zone you’re planning to water? Pipe size can tell you a lot about how much water is available in the zone. Although other factors can reduce flow in your plumbing, pipe size is a good, basic rule of thumb when determining available flow in the greenhouse (Table 1).

run from your source to the zone you’re planning to water? Pipe size can tell you a lot about how much water is available in the zone. Although other factors can reduce flow in your plumbing, pipe size is a good, basic rule of thumb when determining available flow in the greenhouse (Table 1).

Knowing how much water is available in your greenhouse helps determine the size of the zone. For instance, if you have a 30 ft. x 96 ft. greenhouse that you’d like to water using overhead sprinklers with a medium to heavy flow, this information is important. With various available nozzles, you would normally use two lines to water this greenhouse with a total system flow of between 25 and 35 gal. per minute. If you only have a 1-in. line feeding the greenhouse, you’ll have to create two zones because of the flow limit of approximately 18 gpm. Not splitting this into two zones results in starving the nozzles with them performing poorly or not running at all.

When in doubt, measuring the available flow is a foolproof way to ensure you’ll have all the water you require.

Important components

The second most common issue we find when troubleshooting irrigation system failures is a lack of important components. Whether left out because they were misunderstood or to save money, there are a number of simple components that protect the system, ensure that it operates properly and make the system easier to maintain.

• Filters—We recommend that each zone have its own filter. Filter screen size depends on the components being used and should be specified by the system manufacturer. The filter not only protects the nozzles and drippers, but components like solenoid valves and pressure regulators as well.

Recently, we received a call from an irrigation customer with 48 zones of drip irrigation that we’d designed and sold. They called because, shortly after installation, the solenoids were failing to close fully, causing the system to slowly drip from the emitters. During a visit, it was found that they had decided to save money by eliminating the 48 zone filters that we had included in the design. They planned to return these. Upon disassembling several of the solenoid valves, small curls of PVC were found in each of the diaphragms, preventing them from closing. Proper filters would have caught these shavings created during installation. Now someone had to go and clean all 48 valves.

Properly sized and installed filters not only protect against wayward PVC bits, but algae and biofilm formed during the operation of the system.

• Pressure regulators—Systems on city water may exceed pressure ratings for different components. Sometimes this will result in sprays stronger than desired from nozzles, as well as causing components to act incorrectly. Check valves in pressure compensated drippers open at a minimum pressure, but seal against the outlet on overpressure, closing off the flow above their specified range.

• Unions and hand valves—One of the most important things you can do when designing your irrigation system is to plan for failure and wear. Every irrigation system will fail at some point, due to clogging or wear of components. Repair will be necessary. Installing isolation valves and unions in the proper places will make this maintenance much less of a headache.

Imagine that a solenoid to a greenhouse is leaking and most likely needs to be cleaned out. Unfortunately, it was glued in place and the PVC will need to be cut to unthread it. Without a hand valve, isolating the zone, you’ll need to drain the system all the way back to the next valve. In many facilities, this is much further than it should be, requiring much of the greenhouse plumbing to be emptied and recharged.

A simple union ball valve would have made this installation much easier with one component, allowing for the flow to be shut off and easily unthreaded, cleaned and quickly replaced.

Supporting your system

Evenness of the spray pattern of many overhead systems depends on the structure supporting it. One typical issue we encounter often is lack of support for the PVC irrigation and distribution lines, resulting in sagging. Systems installed with uneven supply lines can result in uneven watering of the crop below. Nozzles can become angled and twisted with poor

support.

Pictured: Unions and hand valves should be incorporated when designing your irrigation system to help plan for failure and wear.

Often, irrigation systems are installed in the cooler winter, between crops. Once filled with heavy water and left to sit in the sun, the PVC warms and stretches under the weight.

Supporting piping more regularly can help avoid this scenario, especially for distribution plumbing. Use different components, such as C channel or products like Dramm’s PolyRail, to bridge the longer spans common in greenhouses due to truss spacing. These can ease installation while keeping a very rigid pipe.

Installing your system

Certain steps taken during installation can help ensure your system performs well and has a long life. Beyond the selection of different components and support, as discussed above, is the installation of the system.

In the greenhouse, plumbing usually means PVC. As a grower, you’ll deal with PVC quite often. With that in mind, nothing eases installation like having the right tools.

• Instead of a hack saw, invest in a good PVC ratcheting cutter. Like a big pair of scissors, a ratcheting cutter has a sharp blade that will slice through PVC in various sizes. The ratchet-action helps with the force needed to cut through the pipe, making a straight, clean cut with less time spent cleaning shavings.

• Instead of a hack saw, invest in a good PVC ratcheting cutter. Like a big pair of scissors, a ratcheting cutter has a sharp blade that will slice through PVC in various sizes. The ratchet-action helps with the force needed to cut through the pipe, making a straight, clean cut with less time spent cleaning shavings.

(Pictured: A PVC ratcheting cutter has the force needed to cut through PVC pipe, making a straight, clean cut with less time spent cleaning shavings.)

• Chamfer your pipe-ends. This means to shave off the outer edge so that it’s no longer sharp, but beveled. This eases insertion of the PVC pipe into fittings. More importantly, it prevents the sharp edge from scraping all of the cement off of the inside of the pipe during gluing, helping to ensure a good bond.

• Use primer on your joints. While many dislike the staining of purple-primer, it shows that a joint was properly prepared. There are clear primers available for less unsightly joints. Don’t make the mistake of substituting cleaner for primer. Cleaner cleans the PVC, while primer prepares the surface for the cement. Not using a primer can cause joints to fail and separate over time.

Controlling your system

Choosing how to control your system is an important part of any irrigation automation project. There are many controllers that can provide a good level of automation, while still offering more flexible benefits.

If you have a climate control computer, often additional controllers may not be necessary, as many climate controls have irrigation management built in. While we produce our own line of controllers, we suggest that our customers with climate control computers consider updating them to fully automate their irrigation. Often, these systems have advanced capabilities, such as humidity and light data, to help improve the timing and amount of water needed for each irrigation event.

If you prefer to use a stand-alone controller, look for systems with more advanced options, such as manual operation, the ability to increase or decrease watering without reprogramming the whole controller (“water budgeting”), and curves to increase or decrease watering or misting throughout the day.

There are still many growers that don’t fully trust automated controllers, preferring to make the decision on when and how much to water themselves. We’d still suggest setting up an automated system to these growers. For a very small investment in solenoids and a controller with a manual start option, these growers can still make the decision on when to water, and even how much, if the controller has a water budget feature.

Without the controller, however, the grower must go to each zone and turn on a valve and then wait for it to run the allotted time before manually turning it off. With the controller, the grower can manually activate a series of valves for a specific time and walk away, knowing they’ll start and stop automatically. With a water budget feature, the grower could also easily increase or decrease the volume by a certain percentage, depending on if it was sunny or overcast.

With the automatic setup, the grower also has the option to have the system start automatically on selected days, allowing for an occasional day off.

Designing your system

When planning an irrigation system, sometimes it pays to have the professionals do the work. Twenty years ago, customers would ask to purchase components unassembled at no real savings just to have something for their staff to do between seasons. They would never consider paying someone else to design their irrigation system. Those days are past. Operations are leaner, as are margins. Having an outside firm design your irrigation, and even your complete water management, is no longer a luxury. Companies like Dramm can now provide complete irrigation systems, not just parts that you then have to figure out how to assemble into a system. Basic instructions are typically included, with more detailed plans available for a price.

The benefit to these design services is that all of the components are sourced and supplied as a complete kit, reducing your trips to the plumbing supply, without any additional cost. Often, these designed systems provide not only the basics, but isolation valves, filters, unions and the extras that help the system last and perform over time. Finally, the designers will also consider flow rates and zoning to help optimize the system for your facility.

Optimizing irrigation will become more and more important as water becomes scarcer and more regulated. Using newer, water-saving technologies will help growers produce plants with more precision while mitigating costs as they increase. Understanding of not just the newest nozzles and drip emitters, but the systems themselves, will help growers maximize the benefits of these systems. GT

Kurt Becker is the Executive Vice President—Sales & Marketing at the Dramm Corporation in Manitowoc, Wisconsin.