1/29/2016

Having Success with Organic Growing Mixes

Paul Fisher, Jin Huang, Maria Paz and Ryan Dickson

Organic production of edible and medicinal crops in greenhouses is increasing. At the University of Florida, we’ve been evaluating production of potted organic edible plants for retail sale. This article is primarily intended for growers already using conventional growing methods who also want to produce organic transplants or retail potted products.

Core organic practices of incorporating a small amount of compost in substrates, and increasing the activity of beneficial soil microbes, have repeatedly been shown to prevent plant diseases. Along with other organic principles of biological pest control and minimizing environmental impacts, these approaches can be used by all growers. However, going “fully organic” with USDA-compliant substrates and fertilizers is likely to increase cost and management complexity compared with “conventional” production. Complex soil microbiological processes are involved. Organic substrates and nutrient sources tend to be 10 to 20 times more expensive per unit of nitrogen (N), phosphorus (P) or potassium (K). Inputs, such as compost, can also vary between batches.

In comparison, the conventional approach of using a fairly inert root substrate, along with either polymer-coated or water-soluble synthetic fertilizers, is simpler. With synthetic fertilizers, nutrient availability to plants is primarily dependent on easily-controlled chemical and physical factors.

If you’re going to start producing organic crops, additional knowledge is, therefore, needed to consistently achieve excellent results.

Permitted inputs

Allowed substrate components and fertilizers can be found through the Organic Materials Review Institute (OMRI) and the USDA National Organic Program. Other helpful resources include research by John Biernbaum at Michigan State University, Neil Mattson at Cornell University, Kimberley Williams at Kansas State University, Doug Cox at the University of Massachusetts, and organizations such as the National Center for Appropriate Technology (NCAT).

The main differences between organic and conventional substrates are the type of fertilizer charge and wetting agent. Allowable substrate and nutrient inputs include:

- Commonly-used substrate components—such as peat, bark, coconut coir, perlite, vermiculite and clay. Consider including easily rewetted components, such as coconut coir, or a permitted surfactant, such as a yucca-based product.

- Compost, usually applied at 0% to 20% by volume. Use a compost that’s mature and stable, from a professional supplier who has a consistent process and documented lab testing. Avoid materials with high ammonium (potential toxicity), high electrical conductivity (EC, salt burn), fine particle size (waterlogging), strong smell (indicates ongoing decomposition), herbicide residues (phytotoxicity) or trash (aesthetic issue).

- Rock minerals. Limestone is the main mineral input used for short-term crops. If other minerals are used, such as rock phosphate, they need to be very finely ground and benefit from several weeks of incubation in the substrate before planting because release rate is slow.

- Animal, plant and marine-based products—such as blood and bone meal, alfalfa or soybean meal, seaweed or fish byproducts, or blended products. Avoid products that are high in sodium and chloride. Check with regulators and your extension office on food safety requirements, including use of manure-based products.

The nitrogen cycle

The nitrogen cycle

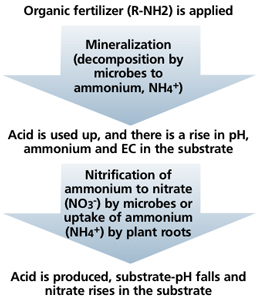

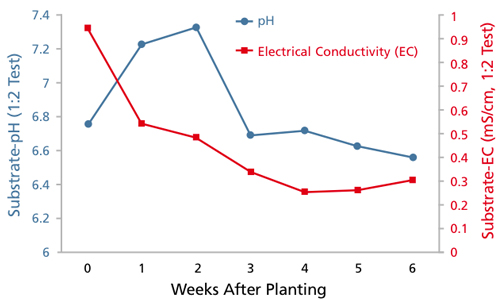

When an organic fertilizer is applied, most N is bound up in large molecules, as indicated in Figure 1. Plants take up N primarily as ammonium or nitrate. One of the first steps after adding organic fertilizer is decomposition into ammonium. This “mineralization” process uses up acid (H+) from the soil solution and raises pH. Compost and organic fertilizers, therefore, often have a liming effect, especially initially, and the ideal amount of lime in an organic mix may be lower than with conventional fertilizers. After ammonium is produced, pH often drops again. Nitrification of ammonium by microbes and plant uptake of ammonium are both acidic. You can see this pH rise and fall in the example in Figure 2, where a granular poultry-based fertilizer was applied to leafy greens immediately before planting.

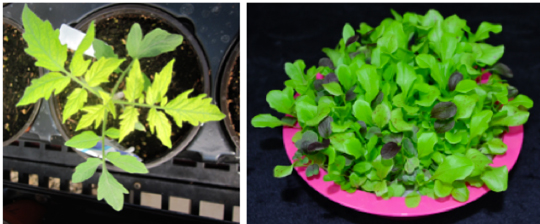

A high pH can cause iron deficiency, as shown on the tomato seedling in Figure 3. Ammonium toxicity is likely if too much fertilizer is applied, pH is low, compost is not mature, and conditions are wet and cool.

Figure 1. The nitrogen cycle affects the nutrients available for plant growth.

To stabilize substrate-pH, some experts recommend incorporating a small amount of compost or a microbial inoculant to jump-start the nitrification process. Others recommend blending the fertilizer into the substrate a month before planting to stabilize pH and salts. Avoiding a high fertilizer or compost content also reduces variability.

Figure 2. Changes in substrate-pH and EC over time. Mixed leafy greens were grown in a peat-perlite substrate with granular poultry-based fertilizer incorporated before planting at 1.4 lb. N/cubic yard. Plants were irrigated with clear water with an alkalinity of 50 ppm CaCO3 and EC 0.4 mS/cm.

There are many guidelines available for organic container substrates. Many of these recipes are likely to cause issues—such as waterlogging, EC or pH problems—and all are highly dependent on the specific batch of compost or other materials used. So it’s critical to run trials with your own inputs, and try to develop as simple and consistent an approach as possible.

A good starting point is using an organically compliant peat/perlite/coir/bark-based substrate produced by a commercial growing media company. Decide whether you want the substrate supplier to incorporate a granular animal or plant-based fertilizer as a base charge. An advantage to adding the base fertilizer yourself is that you have control over storage time before planting, which will affect decomposition of the nutrients and starting pH and EC.

For short-term crops that require a low to moderate nutrient charge, such as leafy greens, all nutrient requirements can easily be provided with fertilizers incorporated into the substrate (Figure 4).

Figure 3, left: Iron deficiency early in a tomato crop. A high pH resulted from mineralization of a high rate of organic (poultry-based) nitrogen fertilizer.

Figure 3, left: Iron deficiency early in a tomato crop. A high pH resulted from mineralization of a high rate of organic (poultry-based) nitrogen fertilizer.

Figure 4, right: Leafy greens are easily grown with organic fertilizer incorp-orated in the substrate before planting.

If you try to provide all nutrients for long-term, high-fertilizer crops using only pre-plant fertilizers, then problems of high pH and EC are likely to occur unless you fine-tune the balance between nutrient availability and plant need. For example, in the tomato crop shown in Figure 5, a low pre-plant charge resulted in healthy initial root and shoot growth, but nutrients started to run out by week 3. Increasing the fertilizer level caused better growth from week 3 onwards, but at a high concentration caused initial stress from high pH (iron deficiency, Figure 3) and EC (reduced root growth).

Figure 5. Root (top) and shoot growth (below) of tomatoes grown in peat-perlite substrate with (from left to right) low, medium or high rates (0.34, 0.94 or 1.54 lb. of N/cubic yard) of incorporated granular poultry-based fertilizer. Plants were irrigated with clear water. At 21 days after planting, the medium fertilizer rate had the largest shoots, but root growth decreased as fertilizer increased.

Figure 5. Root (top) and shoot growth (below) of tomatoes grown in peat-perlite substrate with (from left to right) low, medium or high rates (0.34, 0.94 or 1.54 lb. of N/cubic yard) of incorporated granular poultry-based fertilizer. Plants were irrigated with clear water. At 21 days after planting, the medium fertilizer rate had the largest shoots, but root growth decreased as fertilizer increased.

After four weeks in vigorous crops, available pre-plant nutrients are likely to start running low and applications of supplemental liquid fertilizer are needed every one to two weeks. This is also important when growing a potted crop where your customer would benefit from residual fertilizer—a top-dress of granular fertilizer or drench with liquid fertilizer one week before shipping will boost nutrient levels (and in some cases provides time for any smell to dissipate!).

If direct seeding into a substrate with a high nutrient level, you may need to top-coat the substrate with a low EC seedling mix to get adequate germination. Decompos-ing organic matter is also attractive to fungus gnats, so be sure to have a biological control strategy in place, such as soil drenches of a parasitic nematode.

Use the fertilizer levels recommended on product labels or extension articles. A significant proportion of the applied N may not be available to plants because it’s tied up in decomposition processes. For example, less than 15% of the applied N was taken up by leafy greens over a six-week period in the experiment shown in Figure 2.

Regularly monitor substrate-pH and EC. Send samples to a laboratory because you want to know what nutrients are contributing to EC. However, appreciate that you’re only measuring ions that are available in the substrate solution at one moment in time. An organic substrate has features somewhere between a soil and a soilless substrate, with a large proportion of the nutrients in pools that will not be measured by a water-soluble nutrient analysis. It’s possible to use leaching or liquid fertilizer to lower or raise EC, respectively. Permitted pH-adjusting materials include finely ground limestone to raise pH, or citric acid and elemental sulfur to drop pH.

Conclusions

Growing plants organically will give you an appreciation of the importance of the N cycle and microbial activity because the root substrate is an ecosystem. The ideal recipe will vary depending on your available inputs. Gain experience by starting with a simple approach—use high-quality substrate components similar to what you would expect in a conventional mix, with a low to moderate initial nutrient charge. Add supplemental liquid fertilizer as needed and expect to trial crops at different times of the year before expanding production.

GT

Paul Fisher (pfisher@ufl.edu) is a professor and extension specialist, Dr. Jinsheng Huang is a research scientist, Maria Paz is a biologist, and Ryan Dickson is a PhD student at the University of Florida. Thanks to our industry partners in the Floriculture Research Alliance (floriculturealliance.org) for providing funding for this study.