8/27/2015

Manufacturing Paper Pots for Propagation

Paul Fisher, Jin Huang & Bruce MacKay

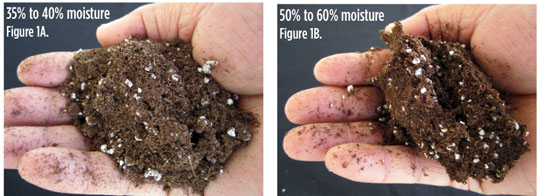

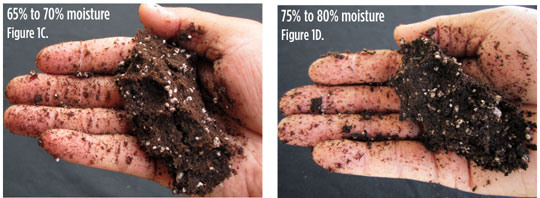

Figure 1A. Substrate at 35% to 40% moisture by weight is too dry for making paper pots or loose-filling trays. At this moisture level (1 to 2 on the 5-point plug moisture scale), the substrate will not hold together as a ball in your hand and has a light tan color. The substrate may be hard to wet on the greenhouse bench and may require an excessively high vacuum setting on an Ellepot machine.

Figure 1B. At 50% to 60% moisture (moisture level 2), the substrate forms a weak ball that breaks with a bounce. The substrate is light brown to tan color. This is the lowest moisture level to produce paper pots and is ideal for loose-filling trays.

Figure 1C. At 65% to 70% moisture (moisture level 3), the substrate easily forms a ball. No water drips with a hard squeeze and the substrate has a medium brown color. This moisture level is the maximum for producing paper pots. For loose-filled trays, it’s too wet, causing bridging between cells and uneven filling.

Figure 1D. At 75% to 80% moisture (moisture level 4), water drips from the ball when squeezed and media is dark brown. Do not use for paper pots or plug trays because equipment will become clogged.

Many liner growers produce their own paper pots using an Ellepot machine. Propagation growers in the Floriculture Research Alliance (

floriculturealliance.org) asked us for help to calculate how much root substrate (growing media) is needed to make up a batch of paper pots in order to plan their substrate needs and calculate tray costs. This article describes our calculator app in

BackPocketGrower.org to meet this need, along with tips on avoiding over-

compaction.

If you calculate the volume of one cell and multiply this by the number of cells per tray and again by the number of trays, that gives the total substrate volume. The volume of a single paper pot can be calculated from a cylinder—remembering back to high school math, the volume of a cylinder is the height (h) times π (3.14) times the radius (r) squared (in other words, hπr2).

In case your Algebra is rusty, we do that math for you in our “Paper pot volume” calculator in

BackPocketGrower.org. You simply enter cell height, diameter, cells per tray and number of trays and the app returns the required substrate volume.

The only challenge is to estimate compaction in the paper pot—in the process of sucking the substrate into the paper pot, a vacuum in an Ellepot machine is needed to provide enough compression to allow the paper to be cut and the substrate to hold together. We surveyed paper pots from eight companies producing paper pots and 22 root substrates used to loose-fill liner trays. We compared the “dry bulk density” (weight of dried growing media) in 25-mm diameter paper pots compared with loose-filled trays with the same volume. Overall, dry bulk density was 32% higher on average in paper pots compared with loose-filled cells. Our calculator in Back Pocket Grower, therefore, includes this 32% compaction factor to estimate the required substrate volume.

The challenge of compaction

For any grower who’s producing paper pots, it’s important to avoid over-compaction because this increases the cost of root substrate per tray. Over-compaction also reduces air porosity by shrinking down the pores (holes in the substrate) that contain air. We found that there was less air for the paper pots (averaging 4.6% of total cell space in an 84 to 105-count tray) compared with the equivalent loose-filled trays (averaging 6.9%). Both paper pots and loose trays had similar water-holding capacity, but when the substrate is over-compacted, then the solid substrate fills the larger pores that contain air. Air is needed for plants to quickly grow roots during propagation.

There are several strategies to ensure that paper pots aren’t over-compacted:

• The vacuum setting in an Ellepot machine should never need to be above 0.2—if such a high setting is needed to hold the pot together, the peat is probably too fine, the mix is too dry or the pot is being cut too short (shorter than the diameter is wide).

• If the substrate is too dry, it normally leads to under-compaction. Under-compaction will cause ripping of the paper during the cutting process and incompletely filled pots. Root substrate will fall out of the bottom of the pot. Dry pots are also hard to rewet by the grower. Add water in the hopper, but be careful to mix thoroughly and evenly.

• If the substrate is very wet, it will be more compacted during pot production. You can check the substrate moisture level by weighing the bags of substrate (where heavier equals wetter) or by testing by hand. For paper pots, a target moisture level is 60% to 70%. If you’re familiar with the 1-to-5 moisture scale for seedling plugs, this would be moisture level 3. At this moisture level, the peat-based substrate will usually have a medium brown color, moisture cannot be easily squeezed out and the substrate will form a weak ball in your hand that will break with a bounce (Figure 1B). Consider posting photos of how the substrate should look at the correct moisture level on the side of the hopper as a quality-control reminder.

• Do not use a fine, s

eedling plug mix in paper pots because the finer the media components, the lower the air porosity. Instead, use a substrate with larger particles that would also be suitable for loose-filling 4- to 6-in. pots, but without sticks and long coconut coir fibers that clog the machine (Figure 2).

Figure 2. A seedling plug mix like this one is too fine for paper pots—the extra compression will mean there’s insufficient air for rapid root growth. Use a coarser mix with larger pores.

• Make sure to place a cardboard or similar barrier between each layer of trays during storage or offset them so that the upper trays aren’t pressing down and compacting the substrate below.

GT

Note: The University of Florida does not endorse any product. At the Floriculture Research Alliance, we do quality testing on many competing propagation products to assist grower success. We thank our industry partners in the Floriculture Research Alliance (floriculturealliance.org) for funding this project.

Dr. Paul Fisher is a professor and Dr. Jin Huang is a post-doctoral research scientist at the University of Florida IFAS. Dr. Bruce MacKay is managing director of thomasBaine Ltd. in New Zealand.