12/27/2012

Horti Fair Moves to the Aalsmeer Auction

Ron van der Ploeg

Gone are the days when the once so powerful Horti Fair occupied the entire RAI convention center. Reduced to four halls, this year’s Horti Fair had to share the Amsterdam exhibition center with the National Trauma Days, where rescue teams and firefighters gave the public a behind-the-scenes look at their work. Visitors were able to see their rescue equipment and cardio-pulmonary resuscitation, but despite the rescue team’s best efforts, it was sad to see how the Horti Fair has drawn to a close in Amsterdam.

Back in 1992, the former NTV moved from Bleiswijk to Amsterdam RAI and was joined in 2000 by the former International Flower Trade Show Aalsmeer (IFTF). Finally united under one roof and one name (Horti Fair), the combined shows evolved into the world’s leading horticultural trade show. In its heyday of 2008 it attracted 50,000 visitors from 100 countries.

The news is that Horti Fair 2013 will be held at the Aalsmeer auction in conjunction with the annual FloraHolland Trade Fair: two different trade shows, which are likely to have their own needs and audience. The announcement alone has left the industry with more questions than answers. Will FloraHolland be able to organize a world event without complicating or hindering the daily operation of its business? Has FloraHolland enough room to host an extra 600 exhibitors? And what about parking space and the inevitable traffic congestion surrounding the auction?

FloraHolland is not a typical exhibition center and the question also arises whether the auction will be able to ensure that its exhibits will comply with all fire and safety regulations adopted by all applicable government agencies. Probably the most underplayed and ignored problem is the venue itself. “The auction floor will be turned into a professional fair venue: one that does justice to the Netherlands’ influential international position in horti business,” said Horti Fair in a press release.

IFTF to double its size

Don’t get me wrong, there’s nothing wrong with the FloraHolland Trade Fair itself. When it comes to new flowers and plants, trends, retailing solutions and merchandising concepts, this trade show offers unrivalled networking opportunities. But the suggestion that these shows represent the Dutch horticultural industry fairly and accurately is misleading and, therefore, cannot be taken seriously. And that’s exactly what IFTF show founder Dick van Raamsdonk from HPP is perfectly aware off. He has seized the opportunity to announce IFTF’s double-in-size strategy. IFTF Expo will take place in 2013 from November 6-8.

Now in its third year, the International Floriculture Trade Fair can look back on a successful show at Vijfhuizen that attracted 18,000 trade visitors, an increase of 6,000 compared to last year.

“IFTF Expo has evolved into a grown-up international floriculture trade show and is ready to grow from 16,000 square meters to 48,000 square meters,” said Dick van Raamsdonk. “With the FloraHolland Trade Fair, which is held at the same time and almost around the corner, IFTF’s home base—Expo Haarlemmermeer—is the ideal location to further take this exhibition to the next level. The available 48,000 square meters of exhibition space, the abundant presence of natural daylight, the large number of available parking spaces [4,500], the excellent accessibility by public transportation [20 minutes from Schiphol Airport] as well as by car [with hardly any traffic jams], contribute greatly to this venue, which is the former home of the 2002 Floriade. I am convinced that because of all that this exhibition building can offer, the IFTF will be able to live up to its name and further grow to become one of the most important floriculture trade fairs in the world. I have been working abroad for 27 years in floriculture and horticulture trade fairs, and it is time to start using all this experience and knowledge as well for a fair in my home country.”

Here are some highlights from Horti Fair 2012:

“Impress the Press” Award

Horti Fair’s “Impress the Press” Award went to a consortium of companies from the greenhouse building industry, which presented the Next Generation Semi-Closed Greenhouse. This greenhouse requires a relatively modest extra investment while leading to 20 to 30% energy savings by using a heat pump and mechanical dehumidification.

The Semi-Closed Greenhouse is currently being tested by tomato grower Lans in Rilland, the Netherlands. Feije de Zwart of Wageningen UR Glastuinbouw is conducting research encompassing 4,000 sq. m. of greenhouse space, which is fitted with an air treatment system allowing greenhouse dehumidification while windows are closed. A closed greenhouse can save up to 4 cu. m. of gas in winter, while the use of a heat pump in combination with a small cogeneration plant plus aquifer can lead to an extra saving of 6 cu. m. Moreover, the mechanical dehumidification can help growers improve their product quality.

The companies involved in the Next Generation Semi-Closed Greenhouse include P.L.J. Bom, Certhon, Van Dijk Heating, Glascom Tuinbouw, Technokas, VB Group, Zantingh, Arend-Sosef, Beemster Elektrotechniek, HAWE Systems Europe and Priva.

Horti Fair Innovation Award 2012

Sercom Regeltechniek and Environmental Monitoring Systems (EMS) BV won the 2012 Horti Fair Innovation Award for their MACView greenhouse gas analyzer, a high-end monitoring system for measuring harmful gases in a greenhouse

environment.

According to EMS’s managing director Jan-Kees Boerman, CO2 addition can cause gases to build up to harmful levels, especially in winter when windows are opened less frequently to save energy. Normally, a low concentration of mono nitrogen oxides NO and NO2 or C2H4 (ethylene or etheen) may not necessarily be harmful to the crop, but long-term exposure, however, can cause diminished growth or even necrosis.

“In up to 80% of the cases, hardly any visible symptoms are being observed, but the grower knows something is wrong,” said Jan-Kees. “It has been estimated that long-time exposure of gases can decrease the productivity by 2 to 10% due to a reduced photosynthesis. MACView is a precision tool (analyzes at parts per billion levels) and is set to ‘make the invisible visible.’”

The MACView Greenhouse Gas Analyser should be connected to a SERCOM climate computer to achieve the best results. The only drawback is the cost: the device is around €22,000 ($28,606) plus another €3,000 ($3,900) for installation. One should also realize that the MACView needs to be calibrated twice a year.

Next generation of phalaenopsis pots

Next generation of phalaenopsis pots

German container manufacturer Pöppelmann has earned a strong reputation in improving its phalaenopsis pots. One good example would be its new, transparent MCO pot, representing the company’s fourth generation of phalaenopsis pots.

Their asymmetrical drainage channels offer dual assurance: they guarantee a secure grip on mesh surfaces and ensure the best possible drainage. The pots guarantee an even air/moisture ratio inside the pot while the side slits and domed holes allow excess water to drain away while still allowing air to circulate. The gap between the dome and the side wall is designed to allow contact between all soil sections and the base of the pot. This ensures that there are no cavities in the soil. A major focus was put on the pot base and its “transportability” and performance on mobile benches and conveyor belts.

This revolutionary new pot features a flat rim, which can maximize available space as the rims can overlap, while the risk of leaf damage is significantly reduced in the absence of sharp edges. Lifting and positioning machines grip the pots securely to ensure a gentle movement of plants and growers can easily de-stack the pots by using the special stacking ridges on the outside in the domed area.

An added plus is the highly transparent material, which encourages the development of healthy roots. The MCO orchid pot even includes patented support tabs to keep the plant stacks vertical, thus making it easy to hold the flower stems securely, showcasing the magnificent flowers in all their glory. They’re available in diameters of 12 and 15 cm (4 and 6 in.).

Solar panel-driven harvest carts

Solar panel-driven harvest carts

Battery driven harvest carts can now be replaced by trolleys, which are fitted with a solar panel. Berg Hortimotive, a specialist supplier of rail systems supporting commercial greenhouse vegetable growing, presented its multifunctional harvest cart with SolarDeck. The cost of the panel itself is €2,000 ($2,600). The payback period is three years, as the SolarDeck delivers important savings in labor and electricity. One extra benefit is that the SolarDeck positively affects the worker comfort, as it provides a more-than-welcome shady area in a usually warm greenhouse environment.

Crop protection in motion

Crop protection in motion

Hortimotion is the name for CleanLight’s new UV robot for low dosage UV treatment that suppresses fungal, bacterial and viral diseases. The company said it has been used successfully in protecting horticultural crops such as roses, tomatoes, cucumbers and strawberries, as well as in field crops such as grapes and potatoes.

For a Dutch rose breeder, the CleanLight system has reduced fungicide application by up to 65% and has rendered plants stronger and healthier. The first UV treatment systems were mounted on a cart that rides along the aisle of the greenhouse, while this self-driving robot moves along a wire infrastructure. The robot is only 640 mm (25 in.) wide and fits easily through narrow pathways. It can drive up to 4,000 meters (13,000 ft.) per day.

CleanLight ensures that plants receive an adequate dosage to kill plant diseases, such as mildew and Botrytis, but not the beneficial insects used against insect pests. The treatment leaves no residues and has been approved as safe by various regulatory agencies in Europe and the U.S.

Stretch and shade

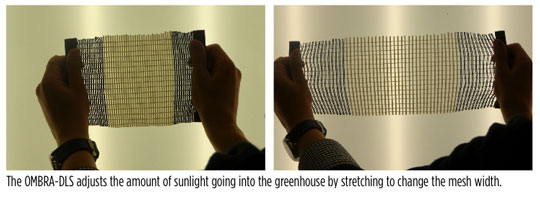

Imagine you had a shade screen made of some mystical elastic textile. And a climate control system that continuously adjusted the amount of sunlight admitted to your greenhouse simply by stretching the screen more or less and thus changing mesh width. It would provide your crop with just the right amount of natural light energy in any kind of weather. It would diffuse light with no need to create gaps between screen parts and subsequent cold air drops or direct sunlight on your crops with a single screen. There is such a screen. Its material is water-, acid-, UV- and fire-resistant and has passed rigorous durability testing. This year OMBRA-DLS was successfully tested in a greenhouse compartment in Honselersdijk, the Netherlands, and the screen is now ready for the market.

According to Babs Japser, OMBRA-DLS offers the grower important cost savings. “With OMBRA-DLS your greenhouse only needs one screen to achieve better results than that are now often achieved using at least two, but mostly three layers of screen. Choosing OMBRA-DLS will therefore reduce installation costs.”

GT

Ron van der Ploeg is editor of Floriculture International based in Aalsmeer, the Netherlands.