9/26/2012

Ball Seed Solutions: Location, Location, Location

Jason Fatten

We recently conducted a study to look at the differences in germination humidity and moisture levels to see if this was why germination rates can vary drastically from the number stamped on the seed package. We measured our own germination chambers in our new Ball Premier Lab where we determine the germination percentage to stamp on the package, as well as a few large plug producers to see the relationship between our lab and those who make a living growing plugs.

Stage One of seed germination is critical for successful seedling development. Simply if the seed fails to grow, so will the seedling. We need the egg to hatch into a chicken.

Our findings: Environment really matters!

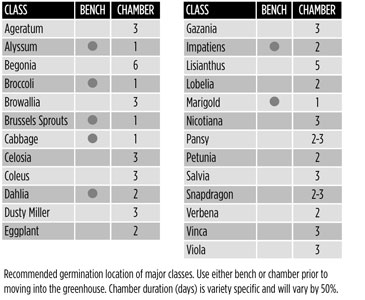

The location where growers begin Stage One of germination varies widely. Some have sealed rooms with strict temperature and humidity control. Others use more basic approaches: using the corner of their shipping dock, throwing another layer of plastic over a greenhouse bay or skipping this step altogether and sending seeded trays directly to the greenhouse. Pay careful attention within the first few days of a seed meeting media. Many issues with quality and uniformity are sourced back to this critical time.

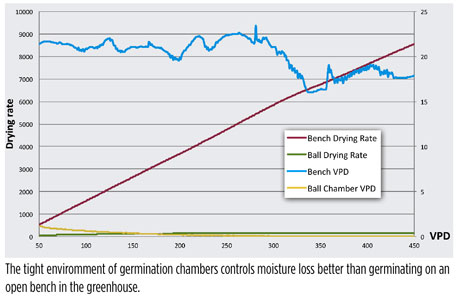

By taking a look at temperature and humidity in some of these germination areas we can calculate the Vapor Pressure Deficit (VPD) of the air. This number is essentially the drying rate of the environment or the environmental demand to move water into the air. Germination involves hydrating or adding additional water to a seed. Therefore, if a seed begins losing water to the air, the germination process is hampered and likely delayed.

The Ball Premier Lab features brand new state-of-the-art humidity and temperature-controlled chambers. The VPD of our germination chambers is near zero. This means we have little need for water to evaporate or move from our trays into the environment.

How did we measure that?

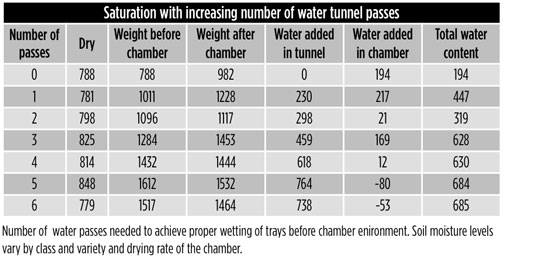

We saturated media-filled trays with varying passes through a water tunnel, weighed them and placed them into the chamber for several days. After about six days, we weighed them again to see the change in water content. Interestingly, the drier trays gained water from the high-humidity environment.

Many of the plug producers we monitored had different results. Even in the most sophisticated chambers, we saw the potential for water loss from trays. Trays weighed less than when they entered the chamber. In trays with the largest water loss, you can see a visual difference in the color of media from different areas of the tray. Not only did the trays dry, they did so unevenly, leading to a problem that’s nearly impossible to fix.

After a closer look, we see instability in germination chambers because of holes, air leaks, poorly maintained equipment and, sometimes, doors left open. Fixing some of these problems can increase germination rates.

Managing media moisture

Think of media in a tray as a sponge. If that sponge is dry, it will want to absorb moisture until it reaches the same moisture content as its environment. The same is true for trays when placed into germination chambers. Certain seed classes require different moisture levels to germinate. Complete saturation is often detrimental to germination. Knowing the VPD or potential for drying during germination and factoring that into the moisture level recommendation gives the proper moisture for germination.

Proper moisture levels during germination are only one of the factors in the germination process. Taking a close look at moisture management in this critical step will help to improve germination rates—hopefully, closer to the magical number we stamp on the package.

GT