2/21/2012

These Old Houses

Jennifer Zurko

Featured on the back cover of GrowerTalks, August 1937

Featured on the back cover of GrowerTalks, August 1937

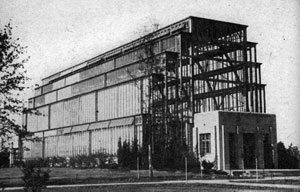

The [photo] pictures an original idea in greenhouse or conservatory construction. It is known as the Jewel Box and will be found in Forest Park, St. Louis. It is designed to overcome the serious loss that hail inflicts on the regulation rounded roof type of structure. The loss of the rounded glass, serious as it is, is not so great as the work of replacing it. An outstanding feature of this construction is that it permits getting at every foot of the glass with an 8 ft. ladder. One’s first interior impression is the lack of graceful lines we are accustomed to in the rounded roof. But this will probably soon wear away; anyway it is quite forgotten when we get inside where the angular lines are more or less covered.

Judging by the number of visitors, the Jewel Box is very popular with the St. Louis Public. It is a commendable departure in the Architecture of this type of greenhouse and reflects credit to its designers.

(Editor’s note: The Jewel Box still proudly serves the gardening public today in the St. Louis area and just underwent a $3.5 million renovation.)

In early 1947, Vic Ball attended the Cornell Short Course held at Cornell University in Ithaca, New York. He made sure to mention a new innovation that provided greenhouses with automatic ventilation.

Talked of and demonstrated at the Cornell meetings. It is simply a hydraulic (water pressure) cylinder which replaces the time-honored crank. Also, this new system includes a thermostatic [sic] control; when the house gets too warm, the thermostat opens the vents—gradually. Lord & Burnham, who are putting it out, expect to offer it for sale within about a year. Costs about $100.00 per run of vents.

Featured on the cover, February 1967

Featured on the cover, February 1967

New Midwest range!

Just completed by Bill Abbot (right) is this 27,000 square foot Ickes-Braun range near Columbus, Ohio. Crops: cut and pot Mums year-round. … It’s a good looking operation—and good equipment, including a 43 x 52 ft. pole type service building that caught our eye. 15 ft. gutter. Labor and material, all but the floor: $4800. Source: Ohio Pole Building, Pataskala, Ohio.

In the photo, from left: Len Shoesmith, Pan-American Plant Mum breeder; Phil Ulery of Ulery’s, Springfield, Ohio—large pot plant growers; Carl Weals, GJB, Inc.; and Bill Abbot.

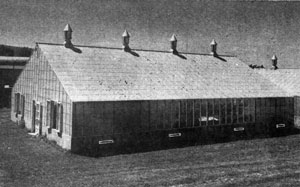

Article titled “Woody’s Ventless Greenhouse” by Vic Ball, October 1952

During the Northwest Growers Meeting at Bozeman, Montana, Elwood W. Kalin of the Floriculture Department at Washington State College at Pullman, Washington, gave an interesting discourse on his new mechanically vented greenhouse.

As is obvious from the photo, instead of regular ventilators there is a row of exhaust fans located along the ridge of the roof. When the house temperature climbs to the set point, the exhaust fans start working and the little inlet louver along the cement wall down near the ground open [sic] so there is a definite movement of air up and out the roof.

The big question—how does it work? Woody says the house is as cool or cooler than a conventional greenhouse in warm summer weather. He reports it is unusually tight and nice for fumigation work. Also, of course, this type of ventilation would be relatively free of drafts such as would occur in a house with conventional vents on a windy day. He also says that the cost of operating the motors is “less than the cost of manual ventilating.”

… As we size the idea up, there are several other points that must be considered. For one thing, it would seem quite obvious that such a house as this without leaky ventilators would very likely be tighter and easier to heat in the Winter. It doesn’t take much of a fuel saving at the present day cost on oil and coal to make a lot of difference over a period of ten years. Presumably with this type of ventilation, during severely cold weather, the grower would just turn the blowers on a few minutes each day enough to provide a little fresh air. In other words, it would probably be a case of doing very little manual operating of the blowers during real cold weather. … It would be most interesting to see whether this new idea of Woody’s will take hold.

In 1973, Vic visited a growing operation in Peoria, Illinois, owned by Jim Peters. His article about Peters’ Greenhouses included a photo of Jim’s new 1-acre poly range.

In 1973, Vic visited a growing operation in Peoria, Illinois, owned by Jim Peters. His article about Peters’ Greenhouses included a photo of Jim’s new 1-acre poly range.

Today, Jim operates several ranges totaling about 3-4 acres, some glass and some poly. He grows a variety of pot/bedding plants. His outlet is mainly high-traffic chains (food and otherwise), plus a fair amount of florist trade, but the thrust here is clearly toward chains.

… Frankly, this is no a “spit-and-polish” operation. A good half of it is a variety of poly structures. There is a shiny new range of Van Wingerden plastic (“Great,” says Jim). A 90-year-old Peoria range supplemented with a lot of Quonsets is the main producer of holiday pot mums (big here). “We cleaned it up, put in a new boiler, added some more work area.”

… “We’re going to stop building this summer, put in good surface walks around the place se we can use small powered tractors to move things. And track. And automatic watering. We just can’t get enough good help, so we’ve got to mechanize more.”

Caterpillar here in Peoria hires 32,000 men. Floor sweepers start at $4.35 an hour.

(Editor’s note: Caterpillar still operates out of Peoria and is one of the largest manufacturers in Illinois.)

For GrowerTalks’ Greenhouse issue, April 1987, Vic surveyed 15 growers to see what they were using to cover their greenhouses. Here are a few excerpts of what he learned.

“… Simple answers, there are none. Surprises—yes! Changes and trends—yes.

- Polyethylene. The ever-present inflated double poly is very big, surely a clear No. 1 in total greenhouse area in the US. Canadian figures show that Canada is divided, nearly evenly, between poly and glass. Expansion toward poly is slowing—giving way some to structured sheets.

- Question: Of all the covering sold in ’86, were there more sales of structured sheets or of glass? Four or five answers to this split both ways—about evenly.

- Fiberglass. The surprise! A major grower or two, a large greenhouse builder, and a reputable researcher, all three, just couldn’t quit talking about how superior production/quality occurred under fiberglass, especially in high-light areas. …

- Total building trend. Not a major building boom, but you get the feeling that a lot of building is going on. And much recovering of existing structures. Total greenhouse area is almost surely up some. Lots of double poly especially in the Southwest and Southeast.”