1/1/2024

Sugarcoating Substrate Security

Jeb S. Fields, Maureen Thiessen & Damon Abdi

There are a few topics that apply to all of us, regardless of crop or production system, like substrates. Much has changed over the past few years, especially substrate security. Growers in the U.S. have routinely relied on foreign-sourced materials, particularly peat moss, and understand the volatility that our global market imposes on availability. Increased demands on peat moss supply stem from a growing customer base as many new horticultural crops convert to soilless culture, as well as a limited harvest window where peat bog access is heavily dependent on ideal weather conditions.

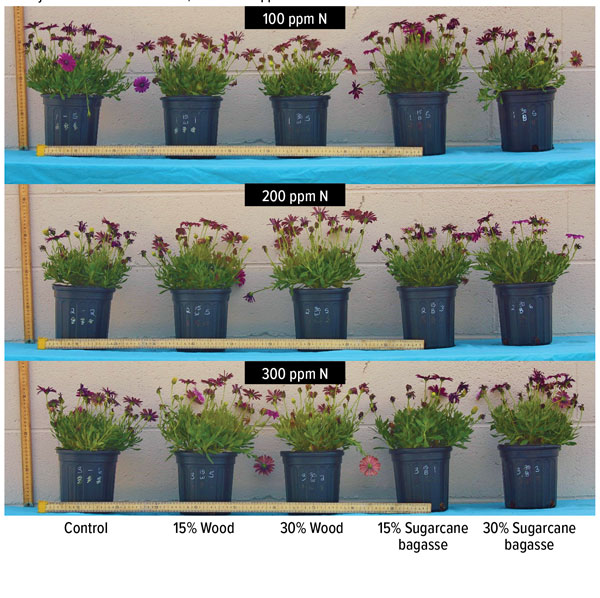

Pictured: An Osteospermum Bright Lights Purple crop grown in a commercially available peat-based greenhouse substrate was amended with 15% or 30% aged sugarcane bagasse or wood fibers. Plants were fertigated weekly with N rates of either 100, 200 or 300 ppm.

Indeed, the peat scarcity we all experienced in 2022 was due to many factors. Supply chain issues limited access to all sorts of inputs, from plastic pots to fertilizer and everything in between. Peat was further limited due to poor weather in 2021 that led to a harvest well below quotas. More favorable conditions in 2022 led to a more sufficient harvest that has allowed supplies to recover, and for some to forget the prevailing limitations, which indicate more long-term volatility than many expect. With another unfavorable harvest year in 2023, we can anticipate another upcoming peat shortage over our next growing season.

While our industry will surely display the resilience it always has in overcoming these shortages, this constant flux from year to year necessitates responses that provide more supply security for our industry and identifying solutions before being forced to use them. There’s much we can do now to prepare for upcoming shortages by not only identifying alternative materials, but also by working out the associated logistics of utilizing peat extenders while supplies are limited. Remember, the worst time to source a solution is when it is dire.

In all likelihood, there’s not some magical, one-size-fits-all solution waiting around the corner. Peat is a nearly perfect substrate component and we shouldn’t expect to completely replace it. Plus, we can say with confidence that just about any biomass available has already been evaluated for potential as a substrate to some extent. A few have been globally successful, like coco coir and wood fibers, but many others didn’t provide the properties needed for adequate plant production and weren’t explored further.

As we continue down this path of developing substrate security and embark in a world that goes beyond peat, some of these materials are worth re-examination due to improvements to processing technologies, as well as greater flexibility to modify growing practices allowing smooth implementation.

A sweet solution …?

Living in southern Louisiana, there’s one such material that shines brighter than the rest: sugarcane bagasse. Bagasse is the spent fibers from sugarcane, after the canes have been shredded and pressed to extract juices that later become table sugar. As substrate scientists, its lightweight and fibrous nature immediately caught our eye as a potential substrate material. As it turns out, we weren’t the first to have this idea.

Sugarcane is a global crop with a long history and uses for its bagasse byproduct—such as in energy production, pulp and paper, construction, and many other applications—have been the focus for decades. Gardeners use bagasse as mulch and an amendment to improve organic matter in soil.

A couple of decades ago, scientists began exploring its potential as a soilless substrate. Bagasse certainly passed the eye test, offering the workability to be readily incorporated as a substrate component. At the surface, it appeared to provide the fundamental features that a substrate should have, with scientists noting the desirable physical and chemical properties of sugarcane bagasse—adequate air and water holding capacities, low bulk density, and moderate EC and pH that were both easily amendable. Unfortunately, it was the third characteristic branch of substrate science, microbiology, that stood in the way.

As one might expect, the high concentration of residual sugars in the bagasse material caused it to quickly rot. This property would not be easy to rectify and scientists at the time quickly moved on to more stable fiber options, such as soft wood fiber, which had similar physical properties and offered more stability.

As one might expect, the high concentration of residual sugars in the bagasse material caused it to quickly rot. This property would not be easy to rectify and scientists at the time quickly moved on to more stable fiber options, such as soft wood fiber, which had similar physical properties and offered more stability.

Today, mountains of bagasse still surround sugarcane processing facilities and storage presents a challenge. Many sugar mills burn bagasse to fuel the mill’s boilers, but as technology advances, less bagasse is needed to power the mill, so the piles grow. The sheer abundance of this material in our own backyards coupled with the need to search for new substrate components caused us to re-evaluate this previously dismissed material.

Sugarcane is roughly 18% sugar, and while much of that is extracted, there’s a significant percentage that remains inaccessible during refinement. Thus, the problem becomes degradation. Sugar is a valuable commodity and any sugar left on the cane or in the bagasse is money that’s quite literally being left out to rot. Thus, extraction technologies have advanced significantly in the decades since bagasse was last truly evaluated as a substrate component. This results in more efficient sugarcane refinement processing, extracting more sugar and leaving bagasse material that contains less residual sugars. Therefore, the bagasse of today should be more biologically stable than in decades past, which could limit the extent that the material degrades.

The trials

That brings us to our research findings. After trialing bagasse at several incorporation rates with mixed results in a gardenia production experiment, our team again set out to evaluate the suitability of bagasse as a substrate, but this time, in short-term crops such as seasonal color crops, whose production time is a few months or less.

With similar physical properties to commercial wood fibers that are penetrating the market, we decided that could serve as a model for bagasse inclusion. Our work involved amending a commercially available peat-based substrate with locally sourced, aged sugarcane bagasse, a mix we aptly coined “sweet peat” and compared it to the same substrate amended with wood fibers to serve as an additional industry standard. To account for possible nitrogen immobilization and determine best management practices, plants were fertilized weekly with nitrogen adjusted to either 100, 200 or 300 ppm.

Substrate physical properties, such as air-filled porosity and water holding capacity, were the same between bagasse and wood blends. Over the production period, substrate pH gradually increased in wood fiber substrates, while remaining more stable in the acceptable nutrient availability ranges with the bagasse. The lower pH of pure bagasse material in general (measured at 3.41 in this experiment) shows promise for bagasse in managing substrate pH where irrigation water has high pH and/or alkalinity or for use in targeted prescription substrates in ericaceous plant production.

As far as plant growth and quality, chlorophyll and blooms were abundant in all substrates and fertigation rates. Simply put, all plants grew well and were healthy. In fact, despite concerns of decomposition and nitrogen immobilization, plants grown in bagasse blends had greater foliar nitrogen concentrations than those grown with the wood fiber blends. Overall, growth and dry mass differences were minimal across substrate treatment and fertigation rate, and all plants were marketable with statistically similar shelf life. These findings support the usefulness of aged sugarcane bagasse as a sustainable, low-cost and domestically sourced amendment that can be incorporated into short-term crop substrate blends in a similar manner as commercial wood fibers without necessitating modifications in fertigation practices or sacrificing crop quality.

Sugarcane bagasse, like many other local or regional bioproducts, can provide a solution for growers, particularly those who focus on short-term crops, that are looking for ways to extend their peat supply. Think of it like this: substrates are similar to a hot cup of coffee, with their rich color and aroma from the organic materials. In both examples, adding a little sugar can go a long way. As differences in the bagasse material may exist from mill to mill, identifying sources and ways to incorporate these materials now will simplify its incorporation into growing operations when it comes time to use the materials.

Moreover, as such a great proportion of our domestically produced horticultural crops rely on foreign-sourced substrates, our ability to seamlessly integrate local materials might even be considered a matter of national security. GT

For further reading: Thiessen, M., J.S. Fields, D. Abdi and J. Beasley. 2023. Sugarcane bagasse is an effective soilless substrate amendment in quick-turn Osteospermum production. HortScience, 58:1170-1177. doi.org/10.21273/HORTSCI17286-23

Dr. Jeb S. Fields (JFields@agcenter.lsu.edu) is an Assistant Professor & Extension Specialist of Commercial Ornamental Horticulture, Assistant Research Coordinator of the Hammond Research Station and Editor-at-Large of the Nursery & Landscape Insider e-newsletter. Maureen Thiessen (MThiessen@agcenter.lsu.edu) is Dr. Fields’ Research Associate at the Hammond Research Station, and Dr. Damon Abdi (DAbdi@agcenter.lsu.edu) is an Assistant Professor of Landscape Horticulture, also located at the Hammond Research Station. All three authors work for the Louisiana State University Agricultural Center.