3/1/2019

Is it Time to Upgrade?

Jennifer Zurko

Greenhouse cooling

By Jeff Messer, Construction Manager, and Tracey Gorrell, Marketing Communications Manager—Griffin

Cooling covers a broad range of equipment; growers have numerous options for managing high temperatures, humidity and general airflow within their greenhouses. What follows are some of the most common cooling product categories and considerations to keep in mind for each.

Cooling covers a broad range of equipment; growers have numerous options for managing high temperatures, humidity and general airflow within their greenhouses. What follows are some of the most common cooling product categories and considerations to keep in mind for each.

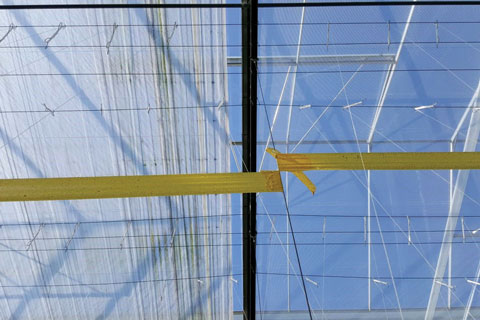

Pictured: Shade cloth can be used to help cool hoop houses, but choose carefully—cloth that’s too dark can restrict plant growth. Image courtesy of Lumite.

Whether you’re talking about exhaust fans and/or horizontal air flow fans, the principles are the same. A well-maintained fan can last up to 20 years. Give fans an annual check-up, making sure blades are clean and belts are snug—but not too tight. As a fan nears the end of its useful life, you’ll often hear it: Listen for bearing noise, which can indicate the fan is losing efficiency and internal parts may have become compromised.

Evaporative cooling systems can be a valuable investment; they’re especially effective in warmer climates. Watch for algae growth in the piping and sump. The area around the pads should be kept clear of weeds to prevent clogging. Even with regular maintenance, the evaporative pads within the housing will break down over time. Inspect yours at the end of each season to check for signs of deterioration and replace as needed to keep them running efficiently.

Pictured: When choosing shade curtains, use open-weave fabric to ensure air can pass through and escape via the ridge vent. Image courtesy of Wadsworth Control Systems.

Pictured: When choosing shade curtains, use open-weave fabric to ensure air can pass through and escape via the ridge vent. Image courtesy of Wadsworth Control Systems.

Ridge and side vents have an average lifespan of roughly 10 years. The rack-and-pinion systems may need periodic adjustments to keep vents moving freely and in sync across all sections. If your vents start binding or causing damage to greenhouse frames, and the maintenance needed to keep them in check becomes too burdensome, it’s time to start shopping.

If it’s properly stored in the off-season, shadecloth for your hoop house can last seven to 10 years. For shade curtains in gutter-connected houses, you can expect 10 to 15 years of service from the curtain fabric. In both cases, the material will eventually begin to crease and bind from repeated use. Prolonged UV exposure will also cause them to become less effective and break down over time.

With motorized shade curtains, racks should be kept well lubricated so the curtains can slide smoothly. If the push/pull system is catching or breaking gears, that’s a clear sign of trouble.

When you’re in the market for cooling replacements or upgrades of any type, the primary consideration is upfront cost versus time. Mechanical options are almost always more expensive to purchase and install. In exchange, with the help of a greenhouse control system, they can be automated and won’t require daily attention to operate.

By contrast, manual options are usually less costly. However, what you gain in financial savings may be canceled out by what you spend in man hours. Varying temperatures can require daily adjustments to roll up sides and chainfall vents, for example, in addition to the time spent monitoring the temperature itself.

While there’s no one-size-fits-all solution to greenhouse cooling, the options can be mixed and matched in a variety of ways to give each operation the right combination of temperature control, efficiency and automation to meet your needs and fit your budget.

Greenhouse coverings

By Mauricio Manotas, President, and Ava Sharp, Marketing Coordinator—Ludvig Svensson, Inc.

We normally like growers to focus on their crop, its quality and yields, which is the essence of their business and what pays the bills at the end of every season. However, an easy rule to follow is that at least once a year, growers need to “look up” and check on the coverings, shades and energy curtains in their greenhouse. What do you have to look for and how can you maximize a possible replacement?

We normally like growers to focus on their crop, its quality and yields, which is the essence of their business and what pays the bills at the end of every season. However, an easy rule to follow is that at least once a year, growers need to “look up” and check on the coverings, shades and energy curtains in their greenhouse. What do you have to look for and how can you maximize a possible replacement?

Pictured: Old energy curtain on the left, brand new Luxous 1147 from Svensson on the right.

Here are some recommendations:

• Let’s start with the obvious points and make sure the energy curtains don’t show any substantial rips or holes. By now you’ve probably been heating your greenhouses for a few months and those rips on the fabric could be the reason your gas bill is unusually high. Patching a hole here and there is a good business practice, but is patching 20 to 30 holes the best use of your labor?

• Light reduction. So you had a great installer 10 years ago and the fabric looks as it was installed “yesterday.” That could be the case and you should keep doing business with that company, but have you measured the light levels on the greenhouse lately? Any product will lose light transition every year due to its exposure to UV radiation, dust, pollen, water, etc. Most likely after 10 years, you’re getting 60% of the initial light that you were getting from the new product. Light has a direct correlation with production of any crop, so maybe it’s time for a change.

• Rebates. Yes, you heard right—rebates! Most states in the U.S. and Canada have very good (yet unknown) rebate programs. They not only apply to new buildings, but also toward energy curtain replacement. Check with your local energy company to be sure, but most of the rebates that we see start six to eight years after the screen is installed. This might help you get a new product at a fraction of the original cost.

• Technology changes every year. It’s likely there’s a newer material out there now that controls humidity better or diffuses light more evenly throughout the crop compared to your current curtain you installed seven or eight years ago. Aluminum curtains that were always a necessity have lost a lot of terrain against more modern and fire-rated light diffusion films.

• Survey your facility. Knowing exactly what you have is the best way of planning for the future. It doesn’t matter if you have hundreds of acres or a couple of hoop houses. Most installers and curtain companies keep records of the product you purchased and when it was installed. Reach out to those companies for information to set up a possible visit or look for rebates or new products. Stay informed!

Scheduling our equipment replacement should be as normal as scheduling routine maintenance on our cars. There’s nothing more painful than realizing in the middle of January that we still have three more months to go with the heaters and our curtains are looking like our aunt’s pasta strainer. Keep an eye on these things to know if it’s time to upgrade or not and maximize your time, energy and overall savings.

Greenhouse heaters

By Nicole Pulyado, Content Writer—Growers Supply & GrowSpan

Greenhouse heating becomes a priority for many growers throughout the year, and if they want to maintain proper climate control to grow healthy crops, those systems eventually need updating. With plenty of heaters on the market, you can maximize your climate control efficiency with an updated system that improves plant health and increases overall profits. Will Kacheris, a growing specialist who designs custom greenhouses and heating systems with GrowSpan, offers insight into best heating practices and how growers can upgrade their operation.

Although it’s important to keep heating systems updated and operating at maximum potential, many growers struggle to know when adjustments should be made. When deciding if it’s time to upgrade your greenhouse heaters, Will recommended keeping an eye on your utility bill.

“If your utility company announces a price hike, it may be time to look at more efficient options,” he said. “Also, some areas offer rebates to those using fewer fossil fuels. Look for those at the local, state and federal level.”

As heaters become less efficient over time, there’s often a direct correlation to steady increases in monthly energy costs. By upgrading your greenhouse heaters, you can save money on a monthly basis, while also qualifying for money back through incentive programs.

After deciding an upgrade is necessary, sifting through the options can be overwhelming, and there are many contributing factors to consider before settling on a heater, especially when utilizing new or different technology.

“It all depends on your need and if you can get a reasonable return on investment,” said Will. “If you are growing a high-value crop year-round that needs to be warm, then a larger upgrade makes sense. However, if you live in a temperate area with minimal heating needs, and your crop is tolerant, it may not be necessary.”

Pictured:

Pictured:

• The Modine Effinity 93 Condensing Unit Heater is one of the most efficient gas options on the market.

• The Modine Hot Dawg Heater comes in both propane and natural gas models, and is a popular choice for its compact, lightweight style.

• For growers with less complex operations, portable space heaters like this one work very well.

• TekFoil Reflective Foil Insulation provides good insulation without breaking the bank.

Every greenhouse is different, from the climate outside to the plants grown inside. While some growers may want to work with a specialist to create a custom overhaul of their heating system, those with less complex operations could opt for powerful space heaters to get the job done. For example, the Growers Supply Fan-Forced Heater is an economical option for smaller growers in need of a portable unit.

For anyone on a tight budget, Will suggested increasing insulation to prevent existing heat from escaping. The TekFoil Reflective Foil Insulation provides growers the opportunity to ensure greenhouse heat isn’t leaking out without breaking the bank.

He offered some advice for growers who decide to insulate: “Adding a second layer of film and inflating the space between is very low cost and doubles your insulation value over standard film. Also, adding insulation layers to the base of your greenhouse through rigid Styrofoam boards or earth mounds can be cost effective.”

Growers with a higher budget have even more heating options to choose from. Propane and natural gas heaters are the most common option, often due to their lower cost and higher productivity, but there are also electric and natural heating options available.

The Modine Hot Dawg Heater, offered in both propane and natural gas models, is a popular choice for its compact, lightweight style. The Modine Effinity 93 Condensing Unit Heater, however, is one of the most efficient gas options on the market. With this heater, the slight increase in upfront costs is offset by its 93% operating efficiency, which immediately reduces energy usage and lowers monthly utility costs.

When asked about heating options for more complex greenhouses, Will said, “Hydronic heat, which is hot water pumped through tubes, is very efficient for larger facilities and you can even use the CO2 from the boiler for your crops.”

This type of dual-purpose heating system not only regulates greenhouse temperatures, but also contributes to healthy plant development, reducing the need for any additional carbon dioxide generators.

Upgrading greenhouse heating doesn’t have to be a stressful process. You should consider your budget, operational needs and the different options on the market, and also consult with a heating expert for guidance and custom-outfitted systems. With a wide product selection and plenty of helpful resources, you can upgrade your greenhouse with ease.

Environmental control upgrades

By Julie Dean, Vice President—Wadsworth Control Systems

No matter how well built, greenhouse controllers don’t last forever. Even if your trusty environmental control is still going strong, there are reasons why it might make sense to upgrade.

It’s important to remember the purpose of an environmental control is to efficiently manage the greenhouse environment. Efficiency includes refraining from running equipment unnecessarily, resulting in higher energy costs, and wear and tear on the machinery. An efficient greenhouse control maintains the climate by integrating all aspects of the environment and responding appropriately.

It’s important to remember the purpose of an environmental control is to efficiently manage the greenhouse environment. Efficiency includes refraining from running equipment unnecessarily, resulting in higher energy costs, and wear and tear on the machinery. An efficient greenhouse control maintains the climate by integrating all aspects of the environment and responding appropriately.

Pictured: An aquaponic greenhouse upgraded to a more complex control to manage dissolved oxygen, temperature probes and power outages for the crop and fish tanks. Each fish tank is a separate zone. The decision also was based on a desire to review data and adjust setting to provide best practices for future crops.

It can be wiser to replace a control that’s unable to add new equipment and sensors rather than piecing together a plan. You may want to take advantage of more advanced technology than your current control can manage, deciding to buy a separate control to work alongside your existing setup. However, this often undermines the success of both controls.

For example, if exhaust fans and CO2 are on different controls, they could run at the same time, wasting the CO2. A newer, more sophisticated control will integrate the functions of all equipment and sensors to work in harmony rather than addressing a single need.

When adding new zones, keeping an environmental control that can’t expand means investing in new controls, which might not communicate with the current system. This can create a piecemeal setup and a future that will continue to compartmentalize. Consider the benefits of controls that share sensor readings, outdoor conditions and stored data settings. There are controllers that grow with your business, allowing the addition of new zones to an existing control or you can design the control to anticipate expansion. This solution uses a single control that can manage multiple zones with different needs.

Companion software, which wasn’t always available or as sophisticated as today’s versions, gives you the ability to view and adjust greenhouse conditions remotely using a smartphone, tablet or PC. Software is key for growers interested in gathering data to replicate successful conditions for future crops, review settings from a similar weather cycle and track energy costs. Reports and graphs give insight into when each piece of equipment is running, time of day and sensor readings. Useful reports can be saved and referenced on a schedule to give more insight. Consider the value of this software in relation to your current controller.

Keeping pace with ongoing regulations may require a more sophisticated control. Dark sky laws require a blackout curtain to restrict light pollution. That means managing another piece of equipment aligned with sunrise and sunset.

Pictured: A change of crops required the addition of misting pumps for the older control, which also had obsolete parts and couldn’t manage. Another feature lacking in the older control was remote access, something the grower required. This grower moved to the Seed system with fewer outputs than the standard model.

Pictured: A change of crops required the addition of misting pumps for the older control, which also had obsolete parts and couldn’t manage. Another feature lacking in the older control was remote access, something the grower required. This grower moved to the Seed system with fewer outputs than the standard model.

Opportunities for funding through state and federal energy grants designed to improve the efficiency of greenhouses by adding energy curtains, improved heating and better environmental controls can make upgrading a timely move.

Competition drives optimal growth in the least amount of time. An older control may not be able to keep pace with opportunities in technology. Equipment management integrated with sensors, such as lighting and irrigation, can increase the potential of your greenhouse. A control capable of modulating LED lights and using a soil moisture probe will benefit crop production.

For smaller operations, the option of using existing infrastructure to minimize investment costs can help. Review the condition of contactor panels since they may be usable in an upgrade. A control that’s working well, but is older, may have obsolete parts. Depending on the size of the operation, migrating to a new control by using the older controls in some zones and upgrading in others works well. You can use the retired controls for parts and take advantage of the opportunity to spread the investment over time. Consider a control like Wadsworth’s Seed 16, with fewer outputs that can expand as you upgrade zones.

It’s always a good idea to review environmental control capabilities with the manufacturer. There may be software or training available that will help make the most of an existing system. Many people don’t get the full value and functionality from their current control.

If you decide to upgrade, find an environmental control that will accommodate future technology and plans for expansion. Forward-thinking companies that have a track record of supporting and investing in their products offer the most viable solution. Investing in a new environmental control means investing in the success of your business for years to come. GT