12/1/2018

Fertilizing Containerized Herbs

Christopher J. Currey

Fertilization is an important part of any crop production program and herbs are no exception. The goal is to produce containerized herbs that are healthy and free of any visible nutrient deficiencies while trying to minimize fertilizer use and unwanted growth.

Fertilizer form

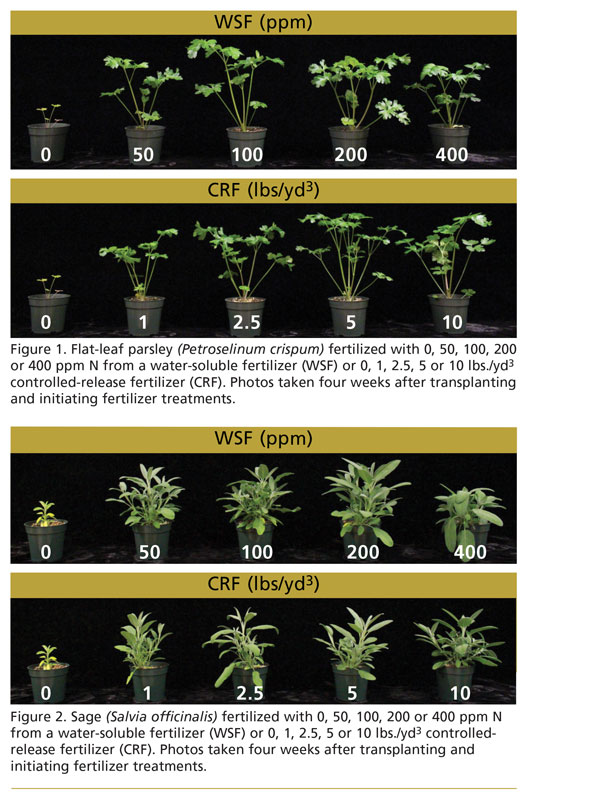

The fertilizer source can affect the growth of containerized herb crops. While it can be challenging to make direct comparisons between water-soluble (WSF) or controlled-release (CRF) fertilizers due to the fundamental differences in nutrient delivery, there’s value in comparing the trends in plant growth.

For the dozen culinary herbs that we’ve grown in containers using WSF or CRF, we found that the plants grown with CRF were generally more compact than those plants fertilized with WSF (Figures 1 and 2). This can likely be attributed to the differences between nutrient provision by the two fertilizer types: CRFs meter out nutrients over the course of their release period, while the nutrients in WSFs are immediately available to plants.

The decision to select WSF or CRF is based on personal preferences, or in some situations, operational constraints. One approach that’s worth considering is using a combination of the two fertilizers, incorporating a low concentration of CRF (1 to 2 lbs./yd3) into the substrate prior to planting, then using a low concentration (25 to 50 ppm N) of WSF during finishing as needed. This approach can take advantage of the more compact growth promoted by CRFs, while allowing the WSF to supplement as needed in response to how the crop is developing (i.e., apply the WSF to boost growth as needed or withhold it to slow down and control growth).

Fertilizer concentrations

In addition to the form of the fertilizer, the concentration of fertilizer applied also affects containerized herb growth (Figures 1 and 2). As you would suspect, as the amount of WSF or CRF applied to herbs increases, growth also increases.

For WSF, 50 ppm produced plants that were more compact compared to higher concentrations. However, 100 ppm N applied at each watering produced plants comparable in size to those fertilized with 200 ppm N.

For CRF, the effect of increasing fertilizer concentration on growth is more proportional for CRF compared to WSF, with plants increasing in size as CRF concentrations increase to 5 lbs./yd3. High concentrations of WSF (400 ppm N) and CRF (10 lbs./yd3) suppress the growth of many containerized herbs. This is likely due to the elevated substrate electrical conductivity associated with high fertilizer concentrations. While the suppressed growth in response to the high fertilizer concentrations is desirable, using high EC as a growth control strategy could damage the health of the crop (i.e., burning the roots).

Restricting fertilizer can be a more successful approach to growth control because, at low substrate ECs, any signs of nutrient deficiency can usually be remedied by applying more fertilizer (frequency or concentration) or supplement with fertilizers to remedy specific deficiencies. However, many of the herbs we’ve grown in fertilizer studies appear to be very efficient in using nutrients and, while they can take up and use excessive concentrations of nutrients, higher concentrations of fertilizer may simply not be needed to achieve acceptable growth due to their efficient use of nutrients.

Organic fertilization

Organic containerized herb production has been increasing in popularity among consumers and producers. With the recent decision by the USDA to continue to allowing containerized plants to be Certified Organic, this trend will likely continue.

Organic fertilization programs for containerized herbs is often a multi-faceted approach to providing nutrients to plants by combining compost in growing substrate, incorporating slow-release fertilizers into substrates prior to planting and supplemental liquid fertilizers post-planting. The nutrient-efficient nature of herbs makes them very well-suited for organic production, where the initiation of nutrient mineralization may result in lower-than-average nutrients immediately available to herbs upon planting.

Potential nutrient disorders

While culinary herbs aren’t notorious for specific nutrient problems, there are a few nutrient disorders to watch for during production. First, you always want to avoid growing plants with such low fertility that lower leaves are yellowing from the lack of nitrogen. This can be a problem for those producers who restrict fertilizer to control growth, but take it too far. It can also happen when plants are held too long without adequate fertilizer, whether as seedling plugs or rooted liners prior to transplanting into finished containers (Figure 3) or as finished plants prior to wholesale or retail sale.

Figure 3. Holding plants too long, whether before transplanting like the basil seen here or at the end of finishing, can result in signs of chlorosis when insufficient fertilizer is provided.

There are some nutrient-specific deficiencies which may occur during production. Interveinal chlorosis on basil is often a symptom of an iron deficiency. There may be a few different causes of an iron deficiency in basil. Again, if you’re restricting nutrients too much in an effort to control growth, insufficient micronutrients may be being provided to the plant. Alternatively, elevated substrate pH from irrigation water alkalinity may also restrict iron availability. Iron chelate can help green basil up quickly.

In addition to iron, magnesium deficiency is another deficiency you may see on basil. Basil has a greater requirement for magnesium compared to other culinary herbs, which is why you may run into this deficiency during production. To prevent or remedy this problem, increase the magnesium in your fertilizer or apply a drench of magnesium sulfate (Epsom salts) at a rate of 1 lb. per 100 gal. of water.

Post-harvest plant performance

An additional consideration for containerized herb growth is the fate of our plants. Is the container going to a consumer’s home to be harvested that evening for dinner, only to have the container thrown away afterwards? Or will the herbs be harvested and the plant allowed to regrow for a few weeks to allow another flush of herbs to be harvested? Or are the plants going home to be transplanted into a garden or raised bed or a patio container or window box planter? These are all common fates for our plants. There’s not much need to worry about the performance of containerized herbs if the plants are going to be thrown away after being harvested. However, if they’re going to be grown on by consumers, whether on a windowsill or a in a garden, our fertilizing practices during production can affect post-harvest performance.

The use of CRF in production clearly adds value to consumers. A three- to four-month release period is the most common formulation of CRF used, yet a containerized herb crop may only take one month to produce and the remaining nutrients will continue to be available to plants while be grown by the consumer.

For herbs grown with low concentrations of WSF, there’s not much residual nutrition in the container at the time of purchase. Increasing fertilizers concentrations to 200 or 300 ppm N throughout production just to provide nutrients for the consumer is unnecessary and it will result in unwanted, excess growth and excessive fertilizer application. Instead, try applying a high concentration of WSF at the last irrigation before plants are shipped or put in retail areas for purchase; the last-minute WSF can boost the amount of residual nutrients in the container for consumers.

The take-home message

Regardless of what approach you use to provide mineral nutrients to your crops, there are opportunities to fine-tune your containerized culinary herb fertilization practices. Whether it’s to use less fertilizer in an effort to control growth or simply reduce crop inputs or add value to your crops for consumers, re-evaluate your current fertilization practices to see what improvements you may be able to make. GT

Christopher J. Currey (ccurrey@iastate.edu) is an assistant professor in the Department of Horticulture at Iowa State University.