9/1/2018

Can a Specific Media Help Shorten Your Crop Time?

Jennifer Zurko

I’m sure you’ve seen this on many marketing pieces or growing information from our industry’s breeders: “Faster crop time for quicker turns.” Or something to that effect.

There are a lot of varieties in the marketplace whose innovative genetics provide you a bit of a head start during production. And the reason why this is important is because they know you want to make the most of your space, time and labor force. Your customers want to be able to keep those plants going out the door and you’re trying to squeeze as many pennies out of that as possible.

The breeders can offer a bit of a hand, but is it possible for you to shave off some propagation time by using a particular input? Say, a specific growing media?

I sat down with Ball Horticultural’s resident technical growing experts—Dr. Will Healy and Dr. Todd Cavins—to ask if there was one type of media that would allow you to turn your crops quicker. And the answer is that there’s no magical solution to cutting crop time because there are so many variables to consider.

Here are some of the things you should be asking yourself:

What’s your problem? That’s the first thing to think about, said Will, because each type of growing media solves a specific issue.

“Let’s just say your soil costs are too high. Well, that automatically eliminates glue plugs,” he explained. “Then you go and say, ‘I don’t like the whole concept of a paper pot because I personally believe it restricts roots and I don’t think I get good root growth.’ Well, that means you need to look at other options. So it really is, what is the problem that you’re trying to solve? Then you can start figuring out your options versus being able to say, ‘This is the best.’’’

What are the different options? Will and Todd group growing media into three different types: “loose fill” (buying in bags of growing-on mix or using amendments like wood fiber, i.e., HydraFiber); “internally stabilized” (glue plugs, i.e., ExCel and Terra Plug); and “externally stabilized” (Ellepots, Growcoons or Fertiss). So there are a lot of options for sowing seed or sticking cuttings, but which one would be the best at helping your plants ready for transplant quicker?

“There’s different media that you use for plugs versus liners and there are a couple of things that dictate that,” said Todd.

In seed production, flats tend to be a higher cell count per flat—for example, 288 and 512 cells per 1.6 sq. ft. These small cells need a fine media for uniform filling and cost of stabilized media can be a little out of growers’ price range. In liners, there are larger, but fewer cells, in that same square footage, so large vegetative varieties tend to be better suited for stabilized media where there’s a large ratio to media to roots.

Comparison data on the different types of growing media is hard to find in one place and from one source, which is why Will and Todd challenged Anthony Soster—a hort student attending Michigan State University—to conduct trials for his summer internship project. (You can find some of his research results in the sidebar.)

“We wanted this to be an objective trial to try to understand how each type compares to the other,” said Todd. “We’re just trying to find the best solution for our rooting stations and customers.”

What are your costs? It depends on the size of your operation—larger growers doing high volume will have very different production costs than a small grower who’s just sowing a few seeds or growing a few cuttings, said Todd.

From strictly a cost perspective, both internally and externally stabilized media are more expensive, but they offer a better starting point for your plants. For example, a glue plug tends to reduce crop time; however, they’re a costlier substrate.

Loose-fill soil may be the “cheapest” alternative, but what you lose is the ability to pull, patch and repair quickly, said Todd, which may not be as good for plug growers who need to be able to fix a tray that may only have 85% of the plugs ready for transplant.

“When you look at insertion rates—pulling one out and replacing it with another one—the cost is less when you use a stabilized media because it’s always easier to take a defined unit and put it into a defined hole than it is to take an amorphous glob and try to cram it into something,” said Will. “The problem is if that tray costs $4.00, that’s 4 cents apiece and that’s 4 cents you’ve just thrown out and that starts to get painful.”

What crops are you growing? One thing they’ve found is that very fast-growing crops, like New Guinea impatiens, don’t need higher-cost substrates because “you practically look at it and it starts to root,” said Todd. But for crops like geraniums or poinsettias—high-value crops that take a long time—you’ll probably want to invest in a different growing media.

Can you change over the type of media you grow in for different crops? Todd said that it’s an unrealistic scenario and most growers primarily use one option.

“You’d have to make sure your workers are trained to know which crop goes in which media,” he said. “It becomes a management nightmare, which is why most people just use one type for everything.”

AND PROBABLY THE MOST IMPORTANT QUESTION …

Are you watering correctly? For years, growers have been racking their brains, trying to figure out seed germination and different soil mixes, but it really all comes down to proper water management, said Todd.

“How many times have you heard, ‘If you have nothing to do, go water?’” said Will, with a smirk. “We pay people to water; we don’t pay them to dry it out. If we paid people to dry plants out to the right level, we would have better-quality plants and Todd and I would be unemployed.”

“It’s one of the core concepts; you’ve got to get that right to get the crop right,” said Todd. “It’s not what it is, it’s what it does. I can take any of these substrates and grow the same quality plant with them if I manage my water differently and correctly for each one.”

Oh, and don’t forget about your “shrink” … Meaning the stuff you end up throwing away. Most of the time, if you start with the proper growing media in the beginning stages, you’ll see less loss at the end.

“Everyone sees reducing crop time as a big deal, but that’s really not the problem,” said Will.

He gave this example: If you want one shelf to hold 15 plants, you have to ask yourself, “How many plants do I have to start with to make sure that this shelf holds 15 plants during the entire season?” If every plant is worth $10, but not every single one ended up on the shelf because you have a soil that has a high degree of variability and the plants didn’t have proper roots on them the first week, you end up throwing out three of the 15 plants. The retailer expects to sell 45 plants in that week at $10 a piece, which is $450. If you only end up with $300 worth of plants because 30% of them didn’t make it or are too late—and you start doing that across 2,000 stores—you’re looking at almost $250,000.

“If you sit down and add up your shrink, there’s just an enormous amount of money that you can use to spend a little more up front,” said Will. “Every dollar you spend up front to make sure you do it right guarantees that you’ll have more dollars at the end.” GT

Summer Project: Growing Media Trials

By Anthony Soster, Michigan State University Student & Ball Summer Intern

Students who intern at Ball Horticultural Company are exposed to a diversity of projects where they can ex-plore a specific topic of their choosing. For my internship project, I dove deeper into the different kinds of media used in the propagation of unrooted cuttings.

Generally, propagation facilities will only change their substrate if they have a problem with their existing media program. For example, maybe their product costs too much, perhaps it keeps the plants too wet or too dry, or it doesn’t hold up well in shipping.

Generally, propagation facilities will only change their substrate if they have a problem with their existing media program. For example, maybe their product costs too much, perhaps it keeps the plants too wet or too dry, or it doesn’t hold up well in shipping.

Pictured: An example of all three types of substrates. From left: loose-filled propagation mix, wood fiber in plastic and glue plug 3.

Paper-wrapped plugs are one of the more common types of media used in the industry and our question was, “If you want to switch your production system from paper-wrapped to another media, how will plant growth and other factors be affected?”

My goal was to look at how different products on the market compare as far as their physical characteristics and performance in the greenhouse. We trialed 16 different products on 15 different species, over the course of 12 weeks. We tested these factors: patch and repair capabilities; water-holding capacity; shipping and root development. Because our question revolved around paper-wrapped plugs, we based watering and mist settings on the optimum for paper-wrapped plugs and then compared all product performance to this baseline.

Pictured: An example of how the roots were read during the trial. All of these would be rated as a 5. From left: glue plug 4, glue plug 1, glue plug 2 and propagation foam.

Pictured: An example of how the roots were read during the trial. All of these would be rated as a 5. From left: glue plug 4, glue plug 1, glue plug 2 and propagation foam.

We grouped substrates into three main classes according to how the products are held together: loose, internally stabilized and externally stabilized. Loose-filled media is popular because of its low cost and flexibility with porosity. The products we tested in this category were: two blends of wood fiber and peat, a growing-on mix, and a propagation mix.

Internally stabilized media is bound together by a glue, and is often more costly, but has been shown to reduce crop time, increasing the number of crop cycles a grower can run in a season. The products we trialed were: a rooting foam product and four glue plugs from various companies.

Pictured: Michigan State University Student Anthony Soster checking his rooting trial during his summer internship at Ball Horticultural Company.

Pictured: Michigan State University Student Anthony Soster checking his rooting trial during his summer internship at Ball Horticultural Company.

Externally stabilized media is the most popular among growers because of its ability to replace empty cells and is at a reasonable price point. These products are often seen as a middle ground between the other two categories. Products we tested in this category were: three different paper-wrapped products—one that’s considered a more sustainable option, one containing a growing-on mix and one containing a propagation mix, as well as a spun plastic product containing a variety of loose substrates.

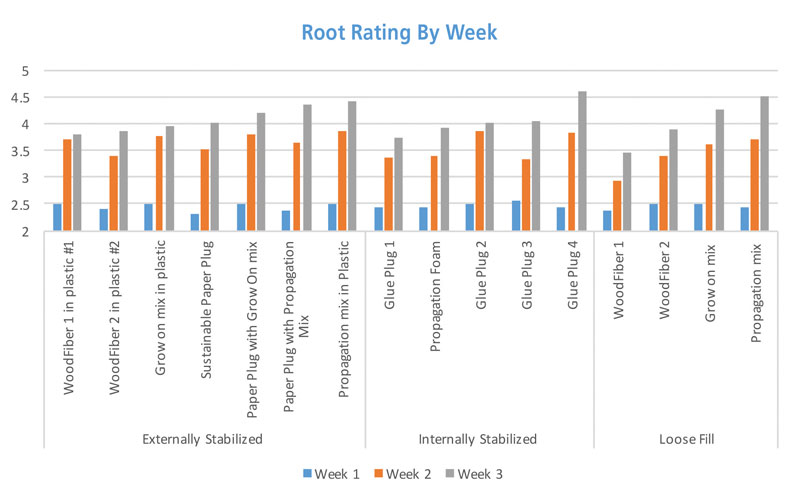

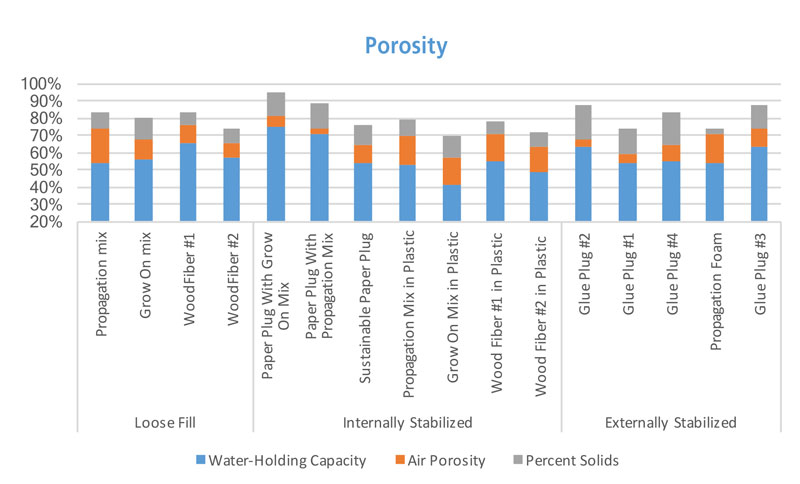

The products were given a 1 to 5 rating on root development seven, 14 and 21 days after sticking. When we look at the data, we find a wide variation in the root ratings at Week 3. (Research results of root development are included in Table 1.) This can partially be explained by the water-holding capacity of the substrate and the availability of water to the plants. The optimum watering conditions for paper-wrapped plugs may result in over-watering some substrates and under-watering others. (It’s important to note that each of these substrates will perform better when treated in their optimum cultural environment.)

Trialing a small section of the greenhouse is important if you’re considering switching. Try to learn how these new substrates respond in your production system—do they require more or less fertilizer, more or less water, and how do they respond to PGR treatments? Training growers also is important, especially in the first year when switching to a different substrate. If close attention isn’t payed to the physical properties of a substrate, then plant growth will likely suffer. GT

Table 1. This graph shows the variance in root development between all of the substrates that were trialed.

Table 2. This graph shows that, on average, loose-filled substrates have higher water-holding capacity. Externally stabilized substrates are generally made of a higher percentage of solids. And internally stabilized media generally vary in their physical characteristics because of their components.