2/1/2019

Lighting Young Plants Indoors

Erik Runkle, Yujin Park, Mengzi Zhang & Paul Fisher

Transplant production is a significant segment of the floriculture industry in the U.S.; for the 15 states surveyed by the USDA, the wholesale value of young plants sold in 2015 was $394 million. In addition to excluding 35 states, this value doesn’t include plugs and liners produced and consumed by the same company, so the actual value of the young plant production industry is much higher.

Figure 1. A variety of high-value specialty crops, including ornamental transplants, can be grown indoors under light-emitting diodes (LEDs).

The growing environment, especially temperature and light, greatly influences plant quality and consistency. Because most young plants are grown during the late winter and early spring, significant production costs for many greenhouse growers in northern latitudes are for heating to maintain a suitably warm growing temperature and supplemental lighting to increase plant quality. In addition, daily and seasonal changes in weather conditions challenge growers to maintain the consistency of greenhouse growing conditions. Variability in growing conditions during the transplant stage usually leads to variability in flowering time and quality of finished plants.

To overcome these production challenges, growers are increasingly interested in producing young plants indoors with energy-efficient and long-lasting light-emitting diodes (LEDs; Figure 1). The possibility of controlling the light spectrum with LEDs offers a way to use light to regulate plant growth and development processes, and thus, produce consistent crops more rapidly with more desirable characteristics. The controlled-environment conditions can also increase the success rate of propagation, which decreases shrinkage and requires less labor (or automation) to patch empty cells in plug or liner trays.

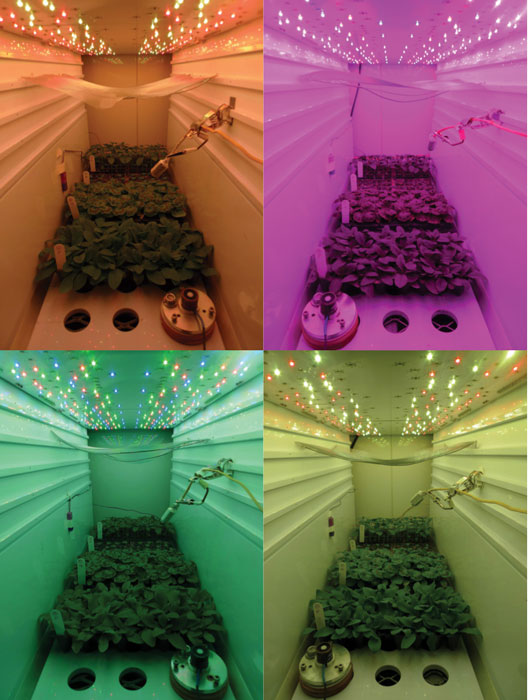

Figure 2. Research being performed with ornamental transplants inside

Figure 2. Research being performed with ornamental transplants inside

custom-designed LED growing modules at Michigan State University.

However, indoor production is expensive. Many indoor farmers report that their three greatest production costs are labor, electricity (for air conditioning and de-humidification) and depreciation of capital costs. The question is, can these high costs be offset by the production of more consistent and uniform transplants, reduced shrinkage, reduced usage of pesticides and growth retardants, and decreased young plant and finish crop times? Some growers are finding for some crops—especially expensive transplants in which shrinkage rate is high—the answer is yes.

Edibles vs. ornamentals

Indoor (vertical) farming is gaining steam in many parts of the world, particularly in North America, northern Europe, the Middle East and much of Asia. Indoor farming usually refers to the production of high-value vegetable crops, such as leafy greens (i.e., lettuce and kale). These crops have year-round demand, a short growth habit and a short production cycle. While there are some similarities with producing young ornamentals indoors, there are also differences.

First, the demand for most ornamental transplants is seasonable, so year-round indoor operation usually necessitates producing different crops during the year. Second, the characteristics desired for leafy greens (large leaves with consideration of taste, texture, leaf color and nutritional content) aren’t necessarily those for ornamentals (compact growth, well rooted, and early or late flowering). The light spectrum influences many of these quality parameters, but indoor lighting for leafy greens isn’t optimized for ornamentals.

In 2011, we started researching indoor LED lighting on seedling plugs using custom-designed LED growing modules (Figure 2). We’ve learned a lot about how different colors (wavebands) of light influence growth and subsequent flowering of floriculture crops. Research expanded in 2017 with the development of the Controlled Environment Lighting Laboratory at Michigan State University (Figure 3).

Figure 3. Research being performed with ornamental transplants in the Controlled Environment Lighting Laboratory at Michigan State University (https://goo.gl/A2xGAa).

Figure 3. Research being performed with ornamental transplants in the Controlled Environment Lighting Laboratory at Michigan State University (https://goo.gl/A2xGAa).

One of our focal points has been far-red light, which we cannot see, but plants perceive and respond to. Far-red light influences extension growth of leaves and stems, and for some plants, can influence flower initiation and development.

We’ve also learned that far-red interacts with other light wavebands, especially blue light, to regulate growth attributes. (Specific research-based information about the light spectrum will be presented in the next several articles of this series.)

Do your LED homework

There are several important considerations when selecting an indoor lighting system and below are some of the major ones. Many of these are also relevant to greenhouse supplemental lighting installations.

• Durability. Lighting fixtures should tolerate horticultural conditions, meaning they can tolerate high humidity and an occasional inadvertent splash of water. Ask about product guarantees, warranties and expected lifetimes.

• Lighting intensity. A target daily light integral for most young plants is 8 to 12 mol·m–2·d–1 for both greenhouse and indoor production. This can be achieved by delivering a photosynthetic photon flux density of 125 to 175 µmol·m–2·s–1 with a photoperiod of 16 to 20 hours. Lower intensities are usually more appropriate when transitioning tissue-cultured plants from vessels to propagation trays, for unrooted cuttings that are sensitive to dehydration or for some shade-growing plants such as ferns or some types of orchids.

• Lighting uniformity. Uniformity of both the light spectrum and intensity are essential for uniform growth of young plants. Horticultural LED fixtures often contain arrays of different LED wavebands, which when blended, emit a desirable light spectrum. However, if plants are placed too close to fixtures, the wavelengths may not be sufficiently mixed, creating spatial variability in the light spectrum. Uniform light intensity is similarly important, otherwise growth (and thus, water demand) will be greater for plants under higher light than under lower light.

• Fixture efficacy. This term refers to the efficiency of a fixture at converting electrical energy into photosynthetic photons of light and is reported in the unit of µmol·J–1. Until recently, the conventional fixture used to deliver indoor lighting was white fluorescent tubes. T8 fluorescents have an efficacy of about 0.85 µmol·J–1. Today, the most efficient LED fixtures for indoor applications are 2.0 µmol·J–1 or higher. This means that LEDs can consume less than half the amount of electricity to deliver a desired intensity, plus less than half the amount of waste heat that needs to be removed by an HVAC system. The fixture efficacy value is especially important for indoor lighting because they operate every day, usually for 16 to 20 hours, for most or all of the year.

• Cost. The number of LED fixtures needed to deliver a desired light intensity depends on the fixture characteristics and height above the crop. Work with a lighting company to generate a lighting plan given your specific operation. They’ll provide you with the number and spacing of the fixtures, and the projected intensity (and variability in intensity) emitted over a surface. Obtain multiple estimates from companies, ensuring you can make apples-to-apples comparisons. The cheapest quotation isn’t necessarily the most economical; consider the costs to install fixtures, as well as their operation costs and projected lifetime. (We’ll discuss how to estimate costs and return on investment in a later article in this series.)

• Customer service. Finally—yet importantly—work with reputable lighting companies with experience and expertise in horticultural lighting. Will their recommended fixture tolerate damp conditions? How will they respond if some fixtures stop working during the first or second year? Will the company still be in business if problems arise? Ask the company about their experiences with horticultural lighting, including specific references or grower testimonials. GT

Acknowledgments: We thank the American Floral Endowment, OSRAM Opto Semiconductors, OSRAM Innovation, Michigan State University’s AgBioResearch, and Floriculture Research Alliance partners and horticultural companies for supporting research and outreach programs at Michigan State and University of Florida.

Erik Runkle (runkleer@msu.edu) is Professor and Floriculture Extension Specialist and Yujin Park is a Post-doctoral Research Associate in the Department of Horticulture at Michigan State University. Mengzi Zhang earned a Master’s degree with Erik and is currently a Biological Scientist at the Mid-Florida Research & Education Center, University of Florida. Paul Fisher (pfisher@ufl.edu) is Professor and Extension Specialist at the University of Florida.