Supplemental Lighting

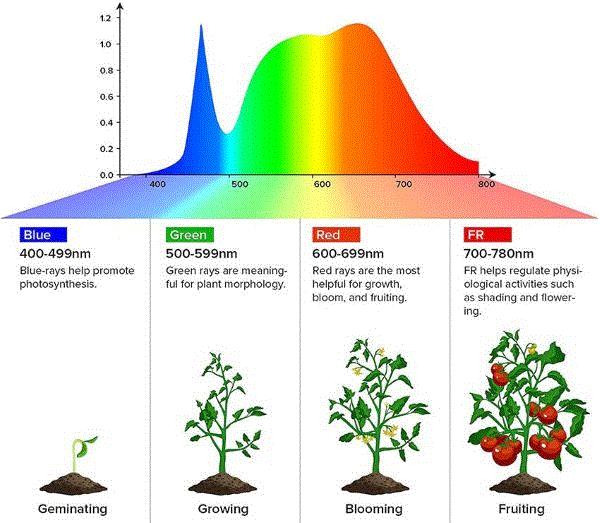

Now that it’s mid-November, daylight savings has ended and the sun is setting before the workday is over. For greenhouses, that shorter daylength means lighting becomes essential to maintaining healthy crop growth. I came across the graphic below the other day.

The spectrum shown is a typical output from a white LED fixture (likely two different color-temperature whites, given the two distinct peaks between 500 and 700 nm). Below the spectrum graph is an explanation of what each color does, or at least an attempt at one. But what does this look like in practice? Let’s look at Little Leaf Farms’ recent post highlighting their lighting system.

Photo Credit: Little Leaf Farms

You can clearly see they’ve opted for a hybrid array, the shotgun approach to spectrum. When in doubt, hit them all. In the photo, there are high-pressure sodium fixtures, pure-blue LEDs, a pinkish white spectrum and a heavier red spectrum. This isn’t to throw shade (pun intended?) at Little Leaf. In fact, I anticipate this array is highly effective for them, and here’s why.

When LED horticultural lighting first hit the market, it went all-in on the idea that chlorophyll primarily absorbs red and blue, so those were the only wavelengths that truly “mattered.” That ignored the world of photomorphogenic responses—put more simply, how plants change their growth form based on spectrum. Including wavelengths like far-red and green can help plants develop more advantageous architectures that capture more total light even if the photon capture is slightly less efficient, ultimately driving more biomass. Meanwhile, infrared wavelengths from HPS and other HID fixtures can strongly influence plant energy balance. They warm meristems, promoting faster growth, while cooler lower canopies reduce respiration. So what does this mean for you as a grower?

We haven’t even gotten to the most important part yet! While vertical farmers can have a lot of fun manipulating spectrum, in a greenhouse, sunlight still plays a dominant role; even in the cloudy, dark places like the Northeast. On cloudy days, electric lights supplement the sun. After sundown, though, your fixtures are the only source of photons. Maintaining a coherent lighting strategy across changing seasons and weather patterns becomes a genuine conundrum.

That’s why the Little Leaf setup makes sense, at least for the near future. A few things stand out. First, a hybrid array lets you take advantage of the infrared benefits of HPS while still leveraging the efficiency gains of LEDs. Balancing heat and light is critical. Second, notice that the far end of the greenhouse appears to lack blue light, while the area with fully grown lettuce is saturated in it. That’s likely intentional: blue light helps “finish” red-leaf varieties, bringing out that vibrant color. It only takes about two days to develop a deep red (check out 29:00–29:15 in this video, the whole thing is worth a watch). Pushing biomass early in the crop cycle, then adding color at the end, is an effective and energy-savvy strategy.

The last point to keep in mind is that lighting is expensive, both to install and to operate. The cheaper, brighter and more electrically efficient the fixture, the better your margins tend to be. Reliability and customer service absolutely matter, so factor that in. In my experience, intensity and efficiency usually come before spectrum, at least to a point.

Let’s have a look at what some of the leading light producers and innovators are working on in the greenhouse industry.

Signify and Grodan Tomato Trial

Signify and Grodan are entering the third year of their tomato trial, part of a holistic effort to reduce energy use without compromising fruit quality. The trial, based in the Netherlands, began in late September with a target light level of 350 µmol·m⁻²·s⁻¹, almost double the conventional 200 µmol·m⁻²·s⁻¹ used in many vine crop greenhouses.

This year’s work will also explore how light is delivered to the crop. Two scenarios, each providing the same daily light integral (DLI), will be compared: one using only top lighting, and another using a combination of top lighting and interlighting. Marcel Raats, plant specialist for Philips at Signify, expects the interlighting treatment to perform best, driven by the combined benefits of additional light AND increased canopy temperature.

Building on insights from the previous two years, Philips/Signify aim to continue refining their lighting strategies alongside their partners. Their holistic approach to optimizing energy, spectrum and crop physiology is not only groundbreaking, it’s essential for understanding how to get the most out of greenhouse lighting systems.

Read more here.

A peek at the trial in progress. Photo credit: Philips

XTi Lighting

Another interesting development in lighting is being pioneered by a company right in my backyard: XTi. They’re focusing on an aspect of lighting we often don’t think about, duty cycle. Duty cycle refers to the fraction of time a system is “on” during each cycle, and in lighting, it describes how quickly a fixture turns on and off, or essentially, how fast it “flickers.”

From a biological perspective, light receptors need a brief recovery period between absorbing one photon and being ready for the next. By manipulating duty cycle, it’s possible to either maximize or avoid activation of these light-sensing pathways, something that applies not only to plants, but to virtually all living systems.

XTi has been leading the charge in figuring out how to use this principle across an impressive range of species: plants, horses, cattle, birds and even people. What’s remarkable is that duty-cycle-based lighting can create measurable physiological effects while also saving energy, simply by pulsing light in a way that doesn’t disrupt biological function.

When you combine duty cycle with spectrum, this approach opens up a vast, and admittedly complex, set of possibilities for how light can be used to grow plants more efficiently and more effectively.

Learn more about XTi here.

Fluence Raptr 2

Fluence has released their next generation of top lighting, the Raptr 2. This 1050 watt fixture has an incredible 3500 µmol/s output, giving it a 3.6 µmol/J efficiency.

I noticed they still lead with the familiar “1:1 HPS replacement” on the front page of their product brochure; it’s not that I disagree with the idea—my hesitation is more like Mitch Hedberg’s take on turkey: “turkey ham, turkey pastrami, turkey bologna … someone needs to tell the turkeys, man, just be yourself.” The 1:1 line has also been a staple of LED marketing since the days when fixtures were 650 watts and 1625 µmol/s.

To be fair, it is impressive that these new fixtures draw power comparable to a classic 1000-watt HPS while delivering far more photons. But it’s worth remembering that lighting performance isn’t about individual fixtures in isolation, it’s about how the entire system works together.

And on that, that is one feature I really like about the Raptr 2. The ability to interface and control these lights on a 0-10 V system with your environmental controller is fantastic. In addition, there’s an option to run the red and white LED channels separate. I anticipate a more comprehensive lighting strategy will use more red in conjunction with sunlight, and a more complete spectrum with the whites at night.

Check out the fixture here.

Fluence's sleek new Raptr 2

Bowery Auction Open Now

From Jen Polanz:

If you’re looking for equipment, you have a couple of days left to peruse the Bowery Farming auction of more than $32 million in new, never-commissioned equipment through Second Bloom. The auction closes November 21 at 11 a.m. Eastern/10 a.m. Central, so don’t delay.

You’ll essentially find everything from breakroom supplies and facility infrastructure to control systems, lighting, precision irrigation and fertigation, automation and material handling, processing and packaging equipment and more. This equipment is from the Locust Grove, Georgia, facility that never opened.

“This facility represents the pinnacle of vertical farming technology—a $70+ million investment in brand-new, fully integrated systems that have never been used,” said Chris Lange, President of SecondBloom Auctions, in a media release about the auction. “For expanding operations, research institutions and technology integrators, this liquidation offers an unprecedented opportunity to acquire proven, commercial-grade equipment at a fraction of the original cost. We’re expecting significant interest from both domestic and international buyers.”

If you do buy, be prepared to pick up quickly; the window for equipment removal is December 1-18 at the site.

80 Acres Featured in Cincinnati’s Power 25

In what can only be described as a banner year for 80 Acres Farms, the Cincinnati Business Courier has named the company to its Power 25 list. The recognition comes on the heels of an exceptionally active stretch for the vertical-farming startup, a year that included raising $400 million in new capital, acquiring several facilities from Kalera, and announcing a strategic partnership with Soli Organic.

Despite this rapid expansion, 80 Acres has remained firmly rooted in the Cincinnati region, now employing more than 300 people and continuing to scale production, automation and distribution from its Ohio base. Their trajectory reflects not only local impact but also the increasing national presence of controlled environment agriculture.

With such accelerated growth, we hope to see 80 Acres continue carving out a strong and sustainable role in the vertical ag space. Read more about this here.

Dr. Jake Holley

Editor-at-Large

Inside Grower

This email received by 34,966 loyal readers!

Interested in advertising in Inside Grower? Contact Paul Black or Kim Brown and they'll show you how easy, effective and affordable it is.